Double-control-valve multi-sealing-tape fuel nozzle

A technology of fuel nozzles and sealing strips, which is applied in fuel injection devices, engine components, machines/engines, etc., and can solve problems such as variable injection hole area, flexible adjustment of fuel injection rules, reduced sealing reliability, and over-positioning. , to improve the fuel atomization effect and meet the effect of flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

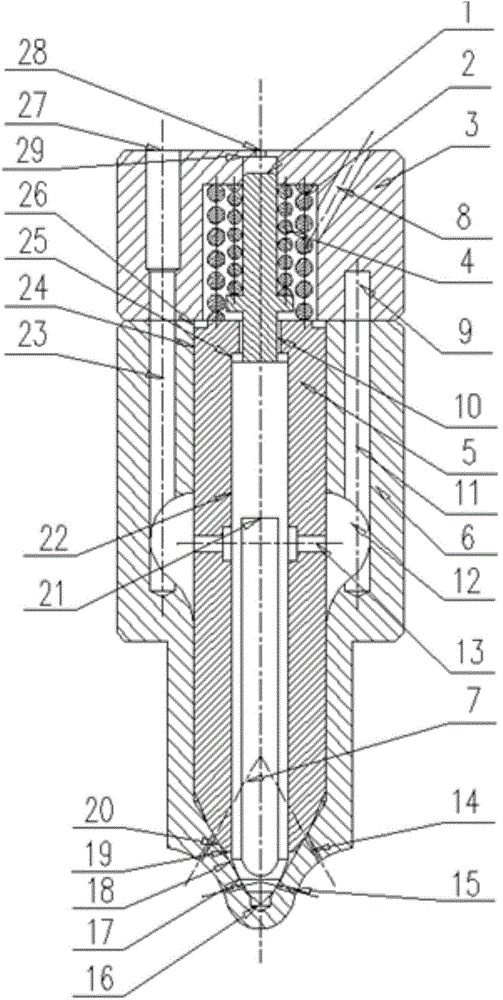

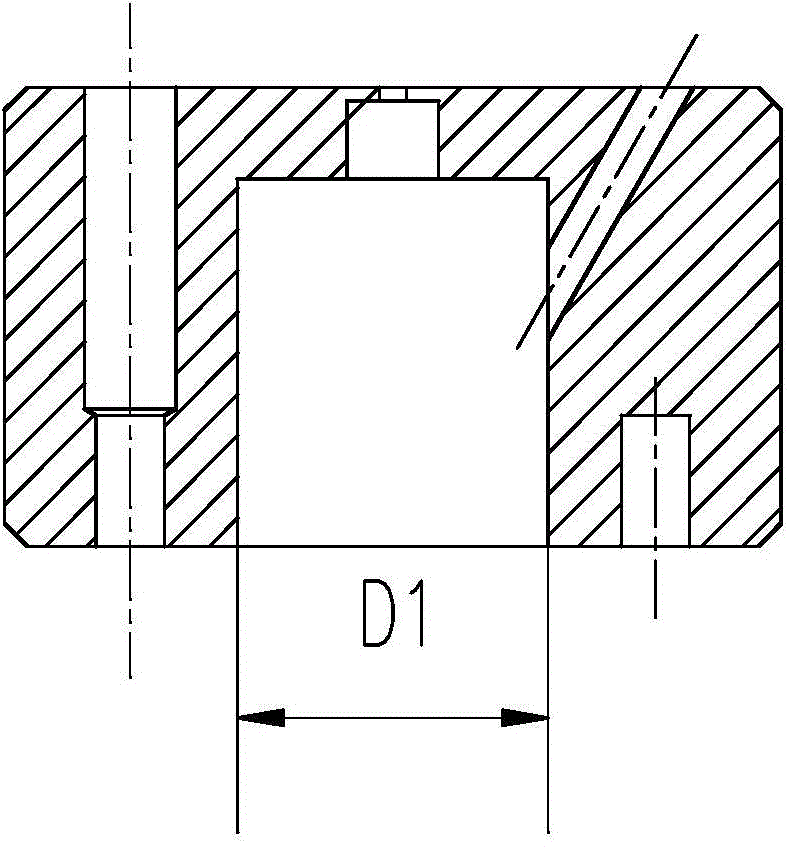

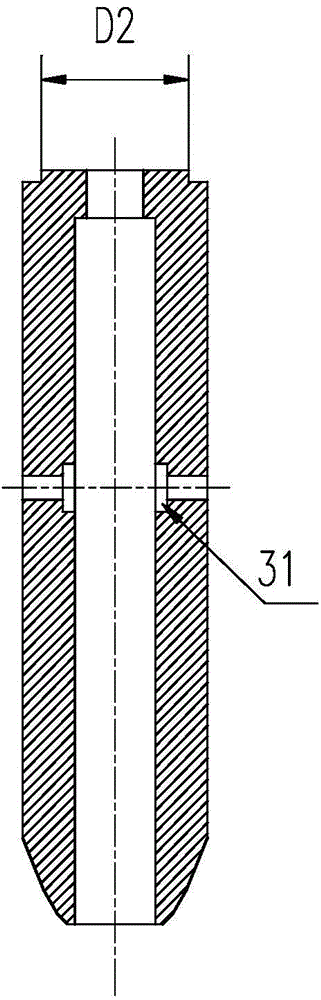

[0031] A dual control valve multi-seal with fuel nozzles, such as Figures 1 to 8 As shown, it includes a nozzle body 6, a sleeve valve 5, a needle valve 7 and an adapter seat 3. The inner cavity of the nozzle body 6 is equipped with a sleeve valve 5, and the sleeve valve 5 is slidingly fitted with the nozzle body 6. The sleeve valve 5 The needle valve 7 is assembled in the inner cavity, and the needle valve 7 is slidingly matched with the sleeve valve 5. The gap between the outer surface of the needle valve 7 and the inner hole of the sleeve valve 5 forms a volume cavity 30; An outer mating surface 24 for high-pressure fuel sealing is formed, and the inner circle of the sleeve valve 5 forms an inner mating surface 22 with the needle valve 7;

[0032] The lower end of the nozzle body 6 is sequentially provided with a main spray hole 15 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com