Double-stator direct-drive wind generating set in impeller locking mode

A technology of wind turbines and double stators, which is applied to wind turbine components, wind turbines, wind turbines in the same direction as the wind, etc., can solve the problems of small stator operation space, increased power generation load, large friction between gears, etc. Achieving the effect of large activity space, mitigation of impact force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

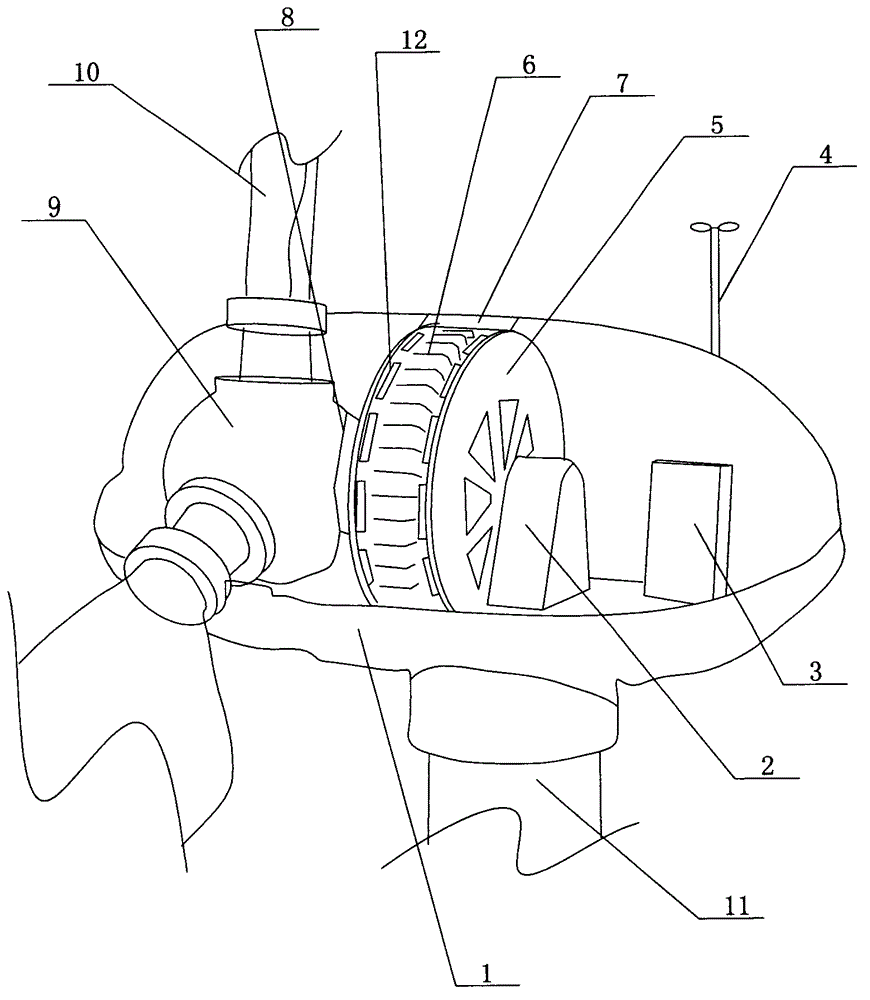

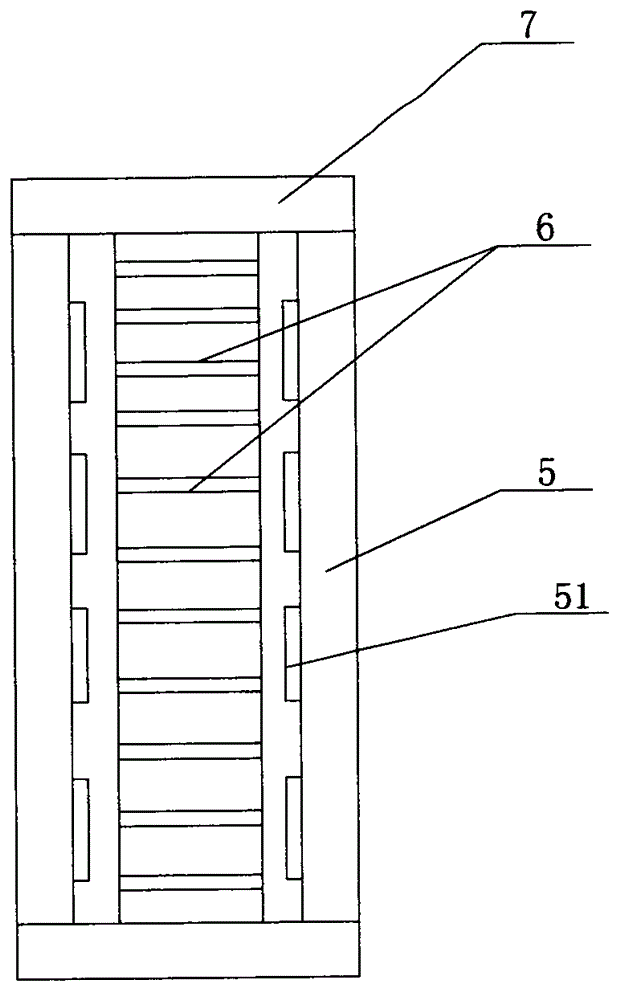

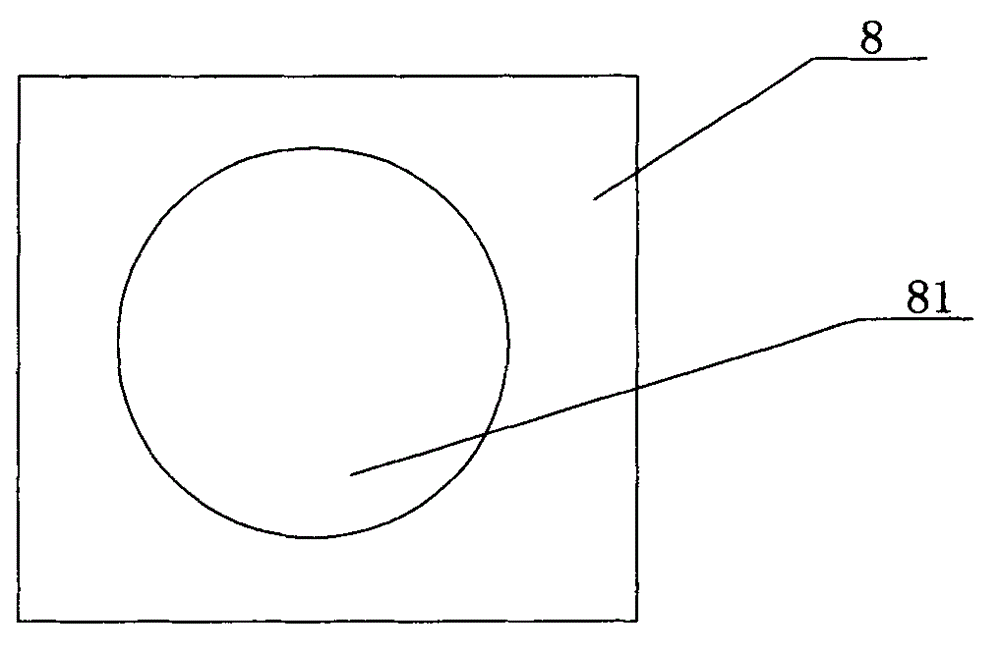

[0020] see Figure 1 to Figure 3 , the specific embodiment adopts the following technical solutions: it includes a nacelle shell 1, a yaw motor 2, an electrical cabinet 3, an anemometer 4, a disk rotor 5, an intermediate stator 6, an outer stator 7, a locking device 8, and a wheel hub 9 , impeller 10, tower 11; the nacelle shell 1 is arranged on the tower 11, is provided with electrical cabinet 3 in the nacelle shell 1, and the anemometer 4 on the outside of nacelle shell 1 is connected with electrical cabinet 3, and one side of electrical cabinet 3 is provided with There is a yaw motor 2, the yaw motor 2 is connected to the right side of the disc rotor 5, the locking device 8 is connected to the left side of the disc rotor 5, several intermediate stators 6 are uniformly arranged in the middle of the disc rotor 5, and the outer stator 7 is sleeved on the outer wall of the middle stator 6, the hub 9 is connected to the locking device 8, and one end of several impellers 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com