Novel granulation machine

A pellet machine, a new type of technology, applied in mechanical equipment, transmission parts, gear transmission and other directions, can solve the problems of waste of raw materials and space, small arc overlap coefficient, unstable transmission ratio, etc., to save space, circular arc The effect of large overlap coefficient and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

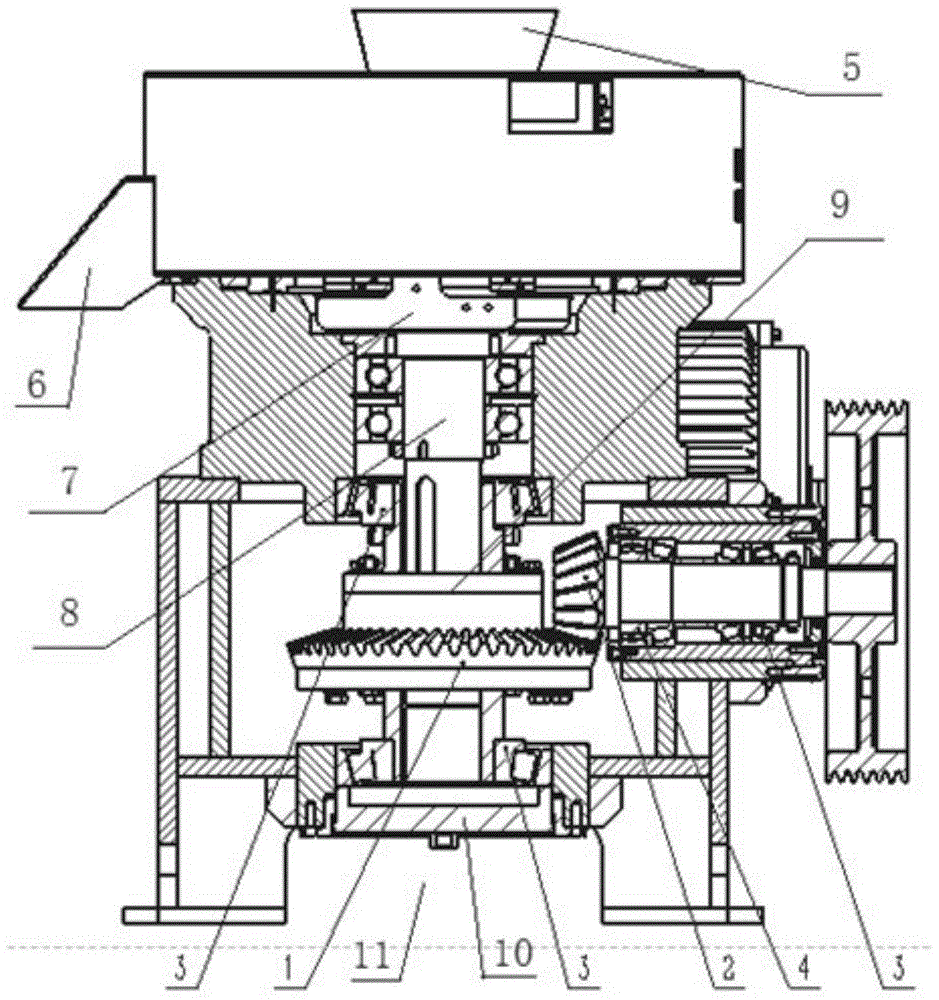

[0014] Such as figure 1 As shown, the present invention proposes a novel granulator, the first gear 1, the second gear 2, the first bearing 3, the second bearing 4, the feed port 5, the discharge port 6, the machine head 7, the main shaft 8, the nut 9. Spindle threaded lower cover 10 and bearing seat 11, spindle threaded lower cover 10 is installed on the upper end of bearing seat 11, main shaft 8 is installed on main shaft threaded lower cover 10 through first bearing 3, first gear 1 is sleeved on main shaft 8 The outer periphery of the second gear 2 is toothed with the first gear 1, and the second gear 2 is installed on the pellet machine body through the second bearing 4, and the upper end of the machine head 7 is provided with a feed port 5 and a discharge port 6. A nut 9 is provided at the joint between the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com