Pneumatic flange type triple-biased butterfly valve

A pneumatic method and butterfly valve technology, applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of poor sealing performance, high cost, and troublesome operation of butterfly valves, and achieve the effects of good sealing performance, reduced waste, and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

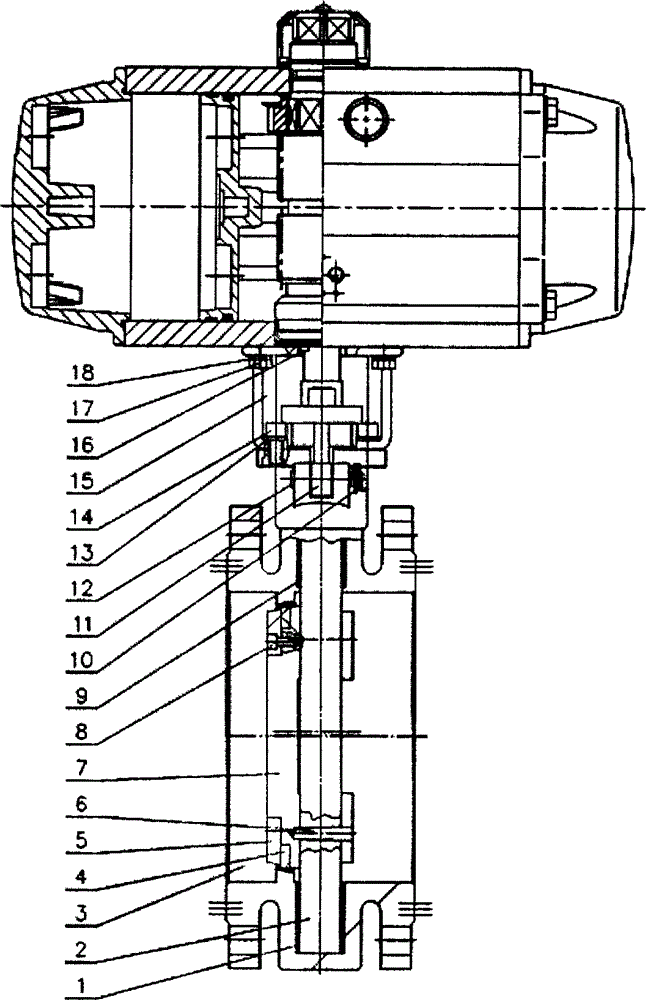

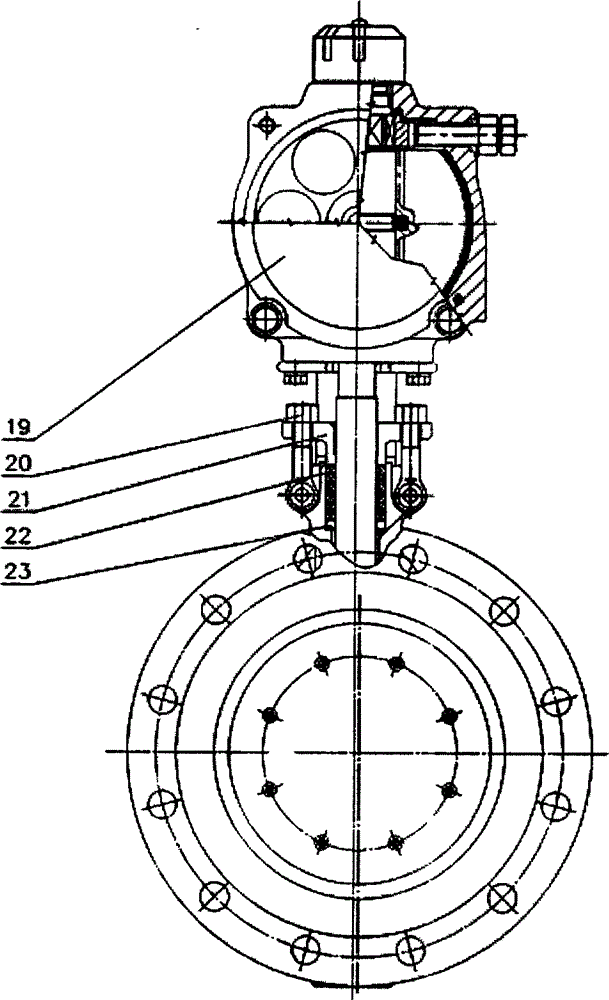

[0013] Such as figure 1 and figure 2 As shown, a pneumatic flanged three-way butterfly valve includes a valve stem 2, a valve body 3, a disc 7 and a pneumatic actuator 19. One end of the valve stem 2 is connected to the valve body 3, and the other end of the valve stem 2 is connected to a pneumatic actuator. 91, the valve stem 2 between the valve body 3 and the pneumatic actuator 19 is provided with a bracket 15 and a packing gland 21 from top to bottom. 17 and key 16 are fixed and locked with the pneumatic actuator 19, the upper part of the valve stem 2 in the valve body 3 is provided with a shaft sleeve 2 9, the lower part of the valve stem 2 in the valve body 3 is provided with a shaft sleeve 1, and the valve body 3 is provided with a shaft sleeve 1. There is a disc plate 7 on one side of the middle of the rod 2, and the disc plate 7 is pressed externally with the disc plate gland 5. The disc plate 7 and the disc plate gland 5 are fixedly connected by screws 18, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com