LED secondary optical lens and manufacturing method thereof

A secondary optical lens and lens technology, which is applied in the field of optical lenses, can solve problems such as energy waste, affecting light output efficiency, and affecting the physical shape of injection molding products, and achieves the effect of uniform spot and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

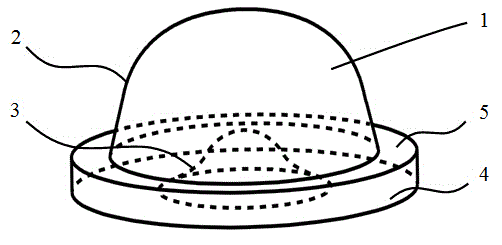

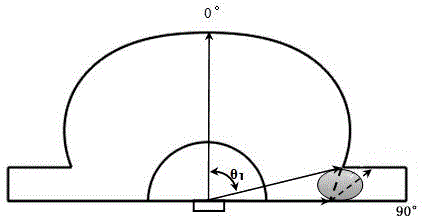

[0037] like Figure 1 to Figure 5 As shown, a LED secondary optical lens includes a lens body 1, and the middle part of the lens body 1 is provided with a convex lens outer curved surface 2, a lens inner curved surface 3 concave in the lens, and the convex lens outer curved surface 2 The starting end is connected with a pancake-shaped lens installation ring, the surface where the lens installation ring intersects with the outer curved surface of the lens is the installation surface 5, and the surface opposite to the installation surface is the base surface 4, and the convex lens outer surface 2 The outer curved surface curve 21 and the outer curved surface straight line 22 smoothly connected with the outer curved surface curve rotate around the central axis of the lens. The outer curved surface straight line 22 intersects the mounting surface 5, and the outer curved surface curve 21 intersects the lens central axis.

[0038] Since the part on the outer curved surface of the le...

Embodiment 2

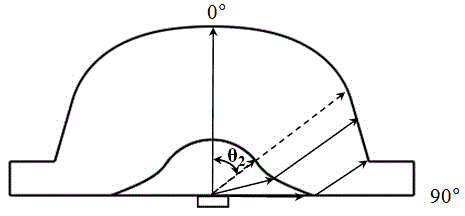

[0049] like Figure 1 to Figure 7 As shown, a LED secondary optical lens includes a lens body 1, and the middle part of the lens body 1 is provided with a convex lens outer curved surface 2, a lens inner curved surface 3 concave in the lens, and the convex lens outer curved surface 2 The starting end is connected with a pancake-shaped lens installation ring, the surface where the lens installation ring intersects with the outer curved surface of the lens is the installation surface 5, and the surface opposite to the installation surface is the base surface 4, and the convex lens outer surface 2 The outer curved surface curve 21 and the outer curved surface straight line 22 smoothly connected with the outer curved surface curve rotate around the central axis of the lens. The outer curved surface straight line 22 intersects the mounting surface 5, and the outer curved surface curve 21 intersects the lens central axis.

[0050] Since the part on the outer curved surface of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com