Automatic molding and casting device for home appliance base products

A product and modeling technology, which is applied in the field of V-method casting aluminum alloy home appliance molds and automatic molding casting devices for home appliance base products. It can solve the problems that the model cannot be coated, the quality of castings is difficult to guarantee, and the operation efficiency is low, so as to facilitate rapid processing. Forming, improving the quality of castings, and good sand mold quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

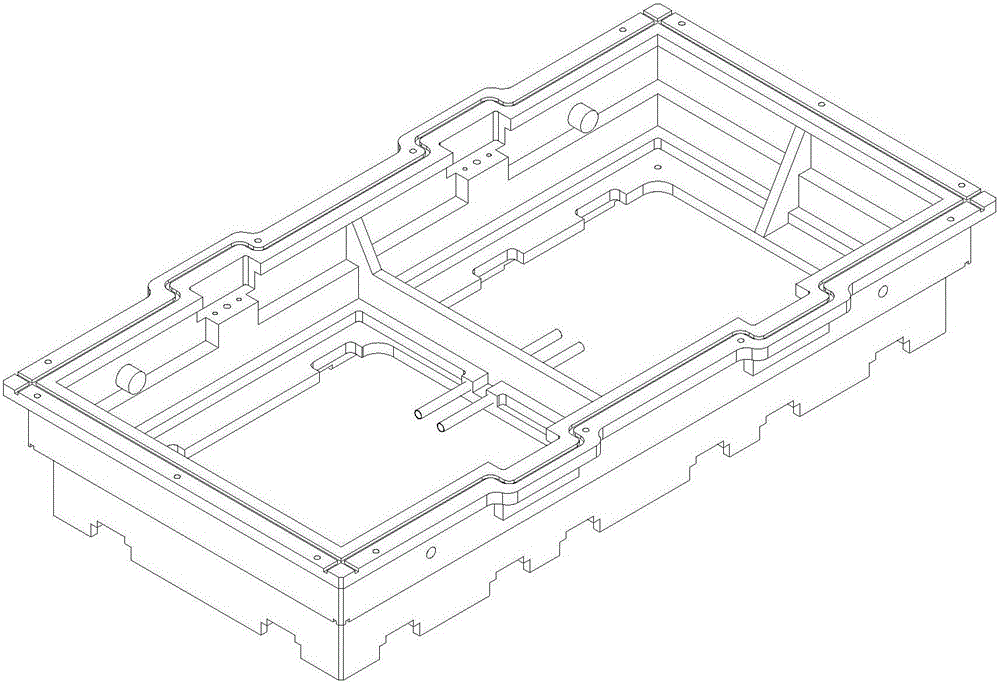

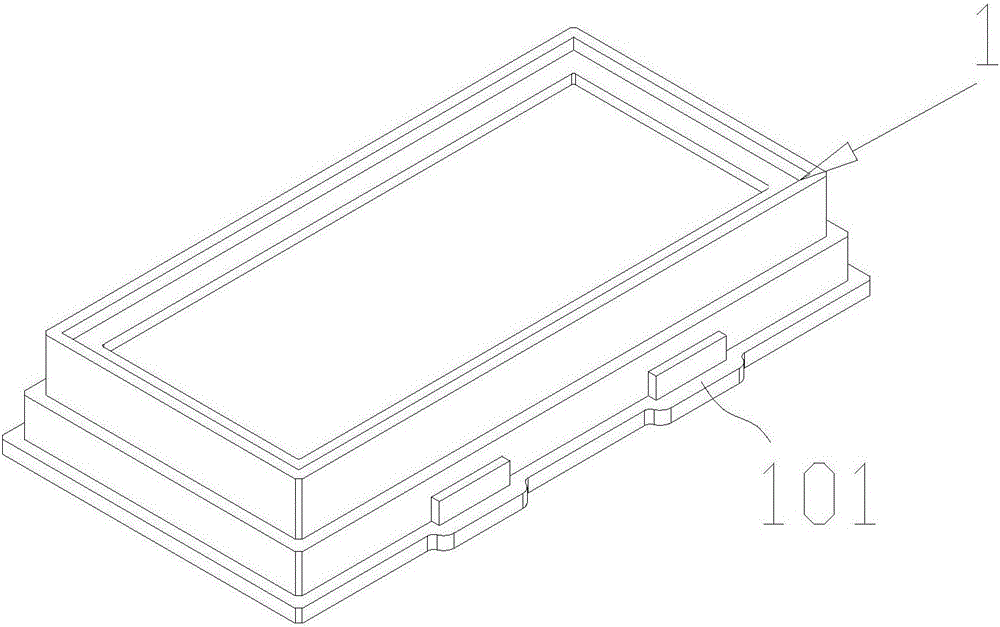

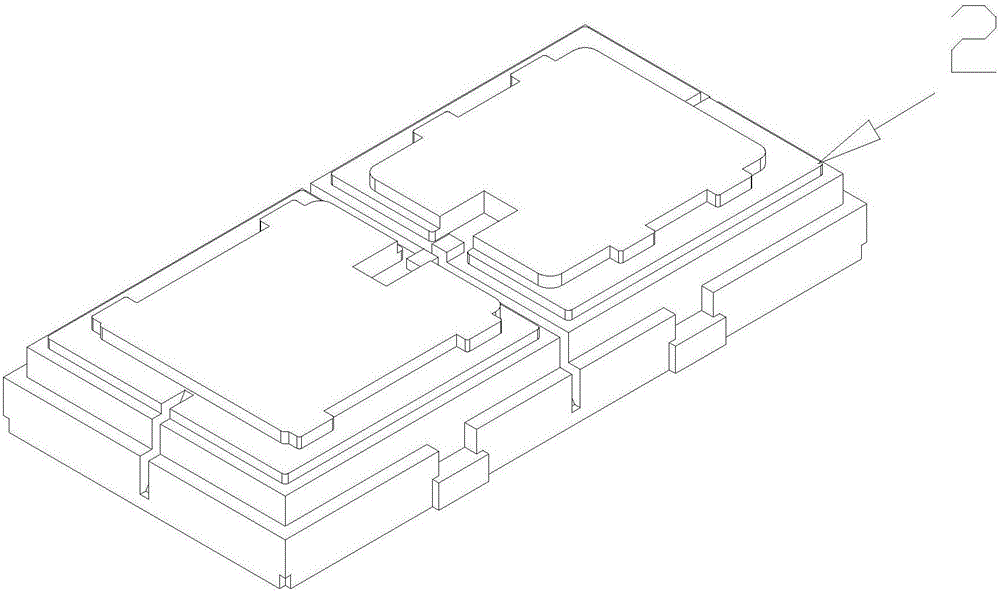

[0040] Such as Figure 1-4 As shown, an automatic molding and casting device for home appliance base products includes a base, a vacuum molding table panel 3 and a sand box. The base is set on the vacuum molding table panel 3. The mold model 2 and the lower mold model 1, the upper mold model 2 is set in the lower mold model 1, the upper mold model 2 and the lower mold model 1 are obtained by parting the base, and the parting surface is selected as the bottom surface of the base, in order to facilitate the modeling Operation, the upper die model 2 is made into a convex shape with the parting surface as the zero point, so that the upper die model 2 and the lower die model 1 are both convex. Both sides of bottom edge of lower mold model 1 are outwardly provided with projections 101, which are convenient to take the model after the molding. The middle of the upper mold model 2 is provided with a hole for connecting the wooden rod of the casting system, and the lower mold model 1 ...

Embodiment 2

[0049] 1. Make the base three-dimensional ( figure 1 As shown) use 3D software to carry out the mold splitting operation, choose the mold parting surface as the bottom surface, and the separated models are the lower mold model 1 and the upper mold model 2, and the upper mold model 2 is the inner shape, but for the convenience of modeling Operation, therefore, the upper die model 2 should be made into a convex shape with the parting surface as the zero point, so that the lower die model 1 and upper die model 2 models are both convex.

[0050] 2. Send the output of the lower mold model 1 and the upper mold model 2 to the model processing workshop for processing, and the obtained casting model is to be cast;

[0051] The materials used in the above-mentioned casting models (lower mold model 1 and upper mold model 2) are made of the following components in parts by weight: 100 parts of ABS, 8 parts of plastic plasticizers, 5 parts of straw powder, monocyclic carboxylic acid 1.5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com