Noise reduction device of range hood

A technology for range hoods and noise reduction, which is applied to the removal of oil fumes, parts of pumping devices for elastic fluids, mechanical equipment, etc., which can solve problems such as insignificant noise reduction effects, troublesome design, and fan system interference. Achieve good versatility and adaptability, reduce transmission to the outside world, and solve noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

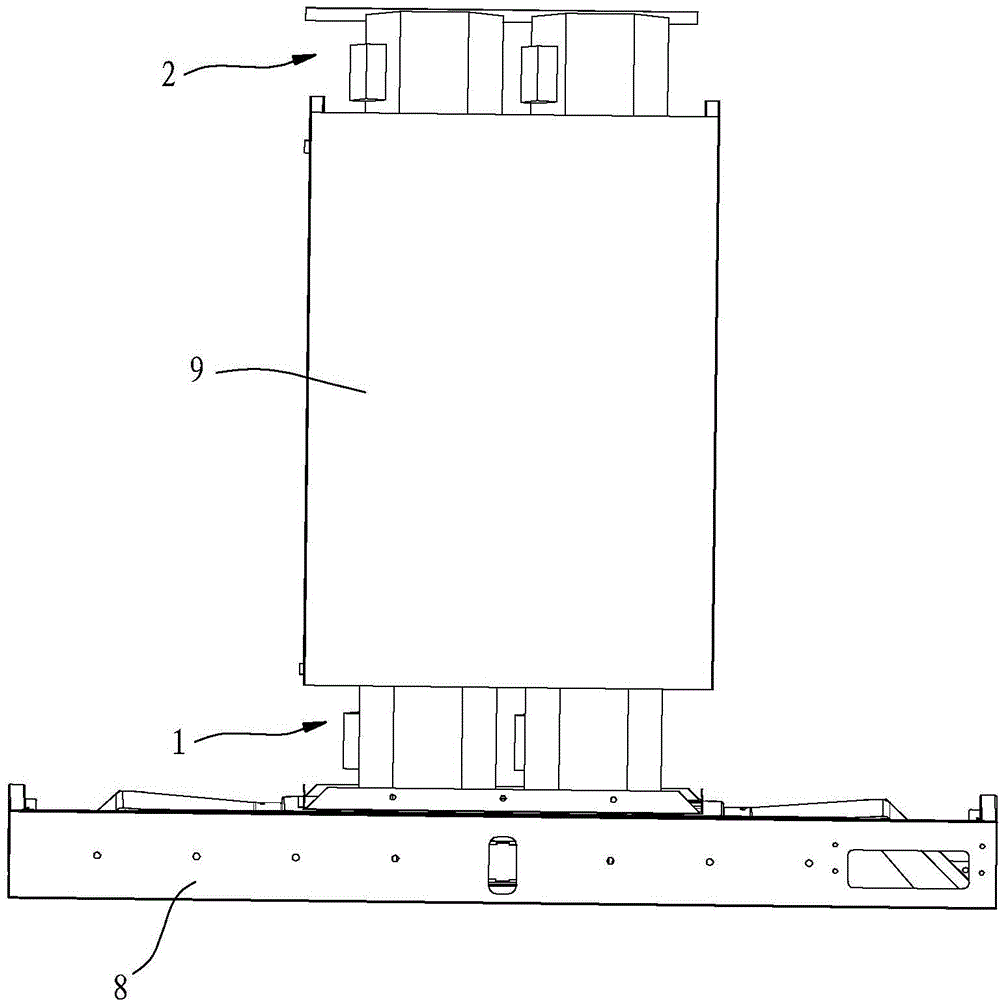

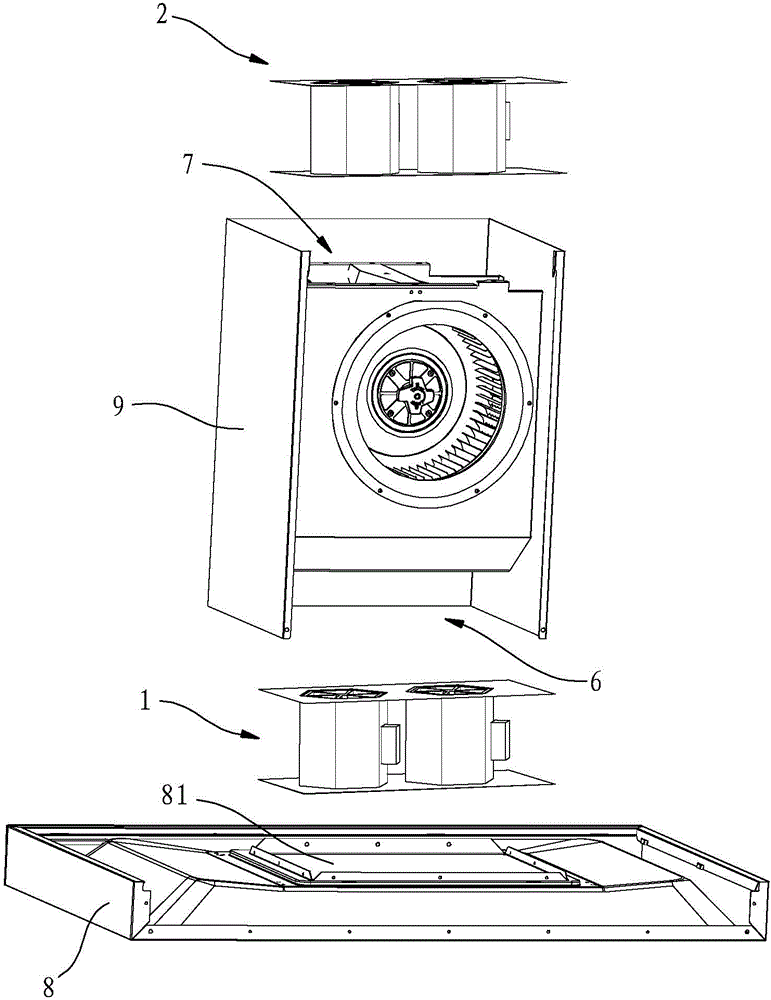

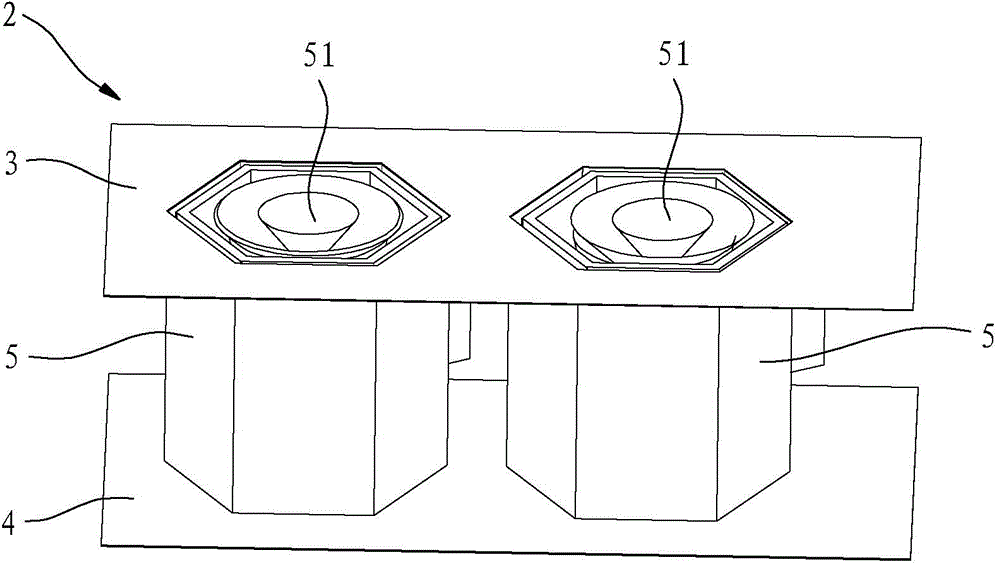

[0026] Such as Figure 1 to Figure 7 As shown, the noise reduction device of the range hood in this embodiment includes two groups of noise reduction devices, the lower noise reduction device 1 is detachably installed on the air inlet 6 of the fan, and the upper noise reduction device 2 is detachably installed on the air outlet 7 of the fan. , the user can freely disassemble and assemble according to the needs, has good versatility, and has good self-adaptability to the noise of any fan system. In this embodiment, the upper noise reduction device 2 and the lower noise reduction device 1 both include an upper mounting plate 3, a lower mounting plate 4 and two noise reduction units 5, and the two noise reduction units 5 in the lower noise reduction device 1 are respectively located at the sides of the air inlet 6 of the fan. On the left and right sides, the two silencing units 5 in the upper silencing device 2 are respectively located on the left and right sides of the air outle...

Embodiment 2

[0036] Such as Figure 8 As shown, the noise reduction device in this embodiment is only provided with a lower noise reduction device 1 at the air inlet 6 of the fan, and the lower noise reduction device 1 also includes two noise reduction units 5, and the structure of the noise reduction unit 5 is the same as that in Embodiment 1. The structure of the sound-absorbing unit is the same and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com