Aerodynamic heat flow measuring device and method for plume field of engine in vacuum chamber

A measuring device and engine technology, which is applied in the field of vacuum plume field, can solve the problems such as the difficulty of measuring aerodynamic heat in vacuum plume field, and achieve the effects of reducing the possibility of interference, avoiding damage, and short transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

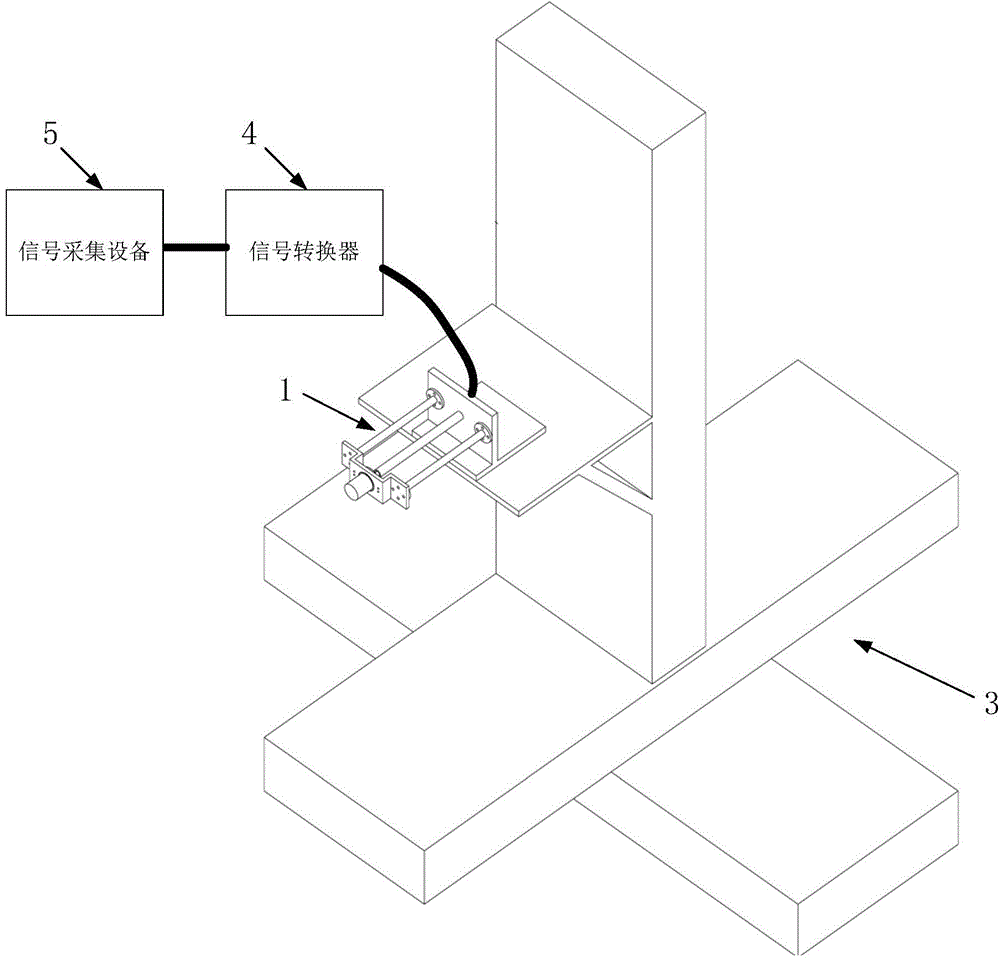

[0026] The present invention is aimed at the aerodynamic heat flow measurement device of the engine plume field in the vacuum chamber, including a bracket 1, a heat flow sensor 2, a three-dimensional moving device 3, a signal converter 4 and a signal acquisition device 5, such as figure 1 shown.

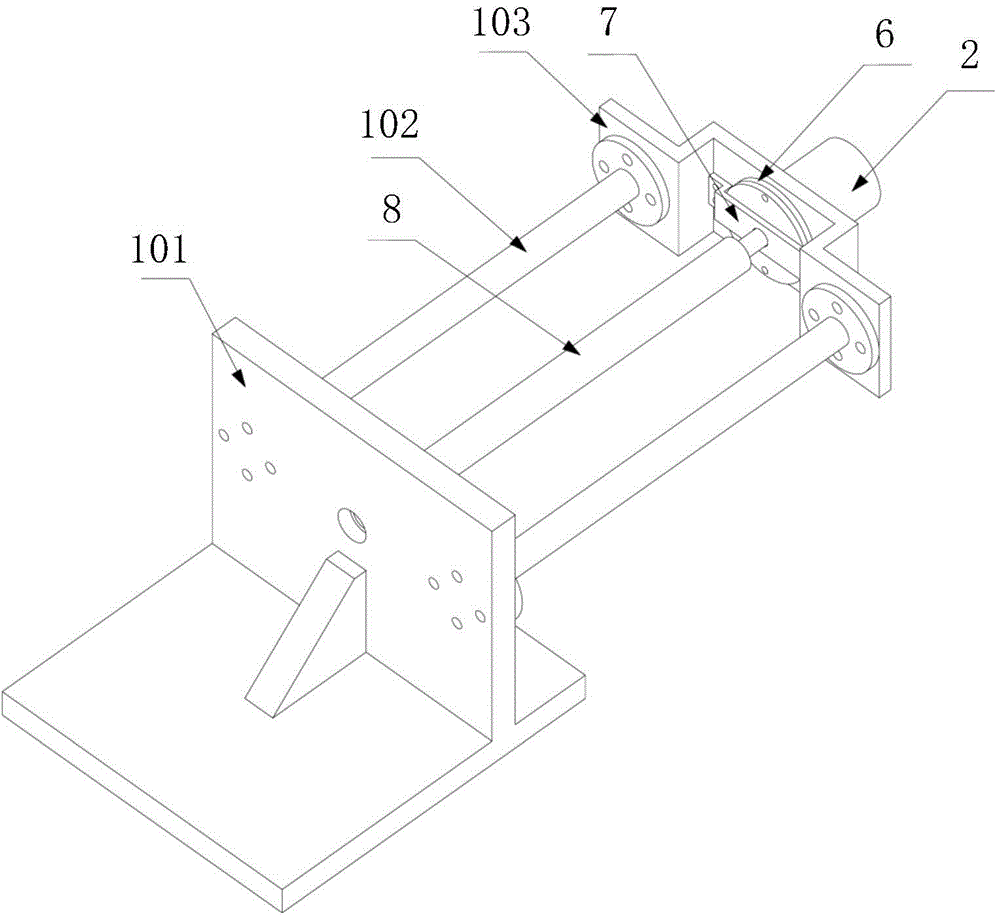

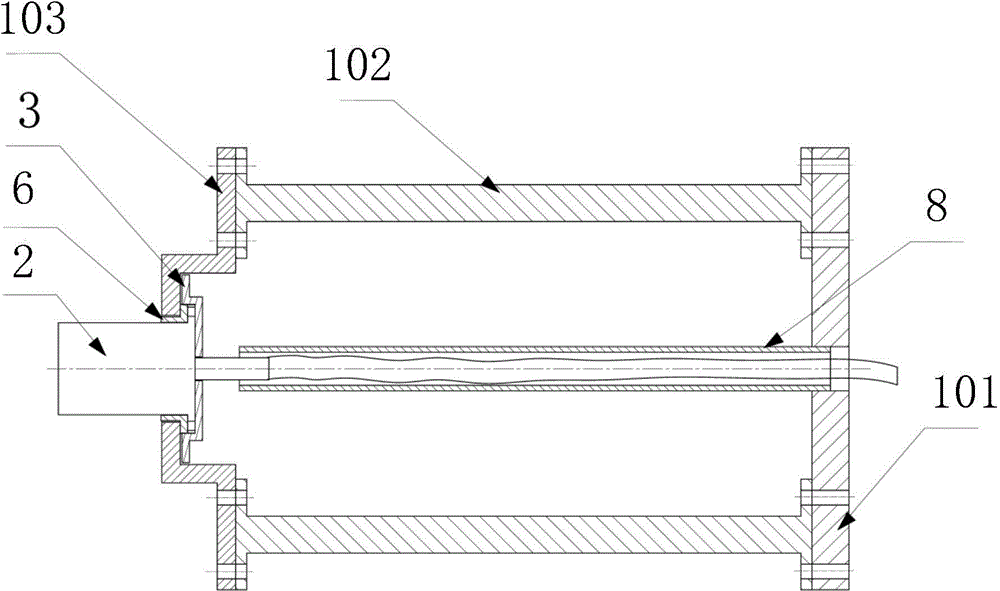

[0027] Wherein, the bracket 1 includes a mounting base 101 , a connecting rod 102 and a sensor fixing plate 103 . The mounting base 101 is made of stainless steel and has a horizontal fixing surface and a vertical connecting surface. There are two connecting rods 102 made of stainless steel with through holes processed at both ends for connecting the mounting base 101 and the sensor fixing plate 103 . The front ends of the two connecting rods 102 are fixedly connected to the vertical connection surface, and the rear ends are fixedly connected to the sensor fixing plate 103 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com