Strip steel edge defect detection identification method

A strip steel edge and defect detection technology, applied in the field of cold rolling manufacturing industry, can solve problems such as difficulty in automatic identification technology, and achieve the effect of improving detection precision and accuracy, and accurate and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the strip steel edge defect detection and identification method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] High-precision laser surface topography measurement technology has developed rapidly in recent years. Today, the measurement accuracy and scanning frequency of civilian-level line laser technology have reached 0.01mm and 30Hz, respectively, which basically meet the conventional industrial requirements. The strip edge defect recognition technology developed based on laser surface topography measurement technology has important academic value and engineering significance for improving the quality of high-performance cold-rolled sheet in my country and developing and forming high-precision defect detection technology.

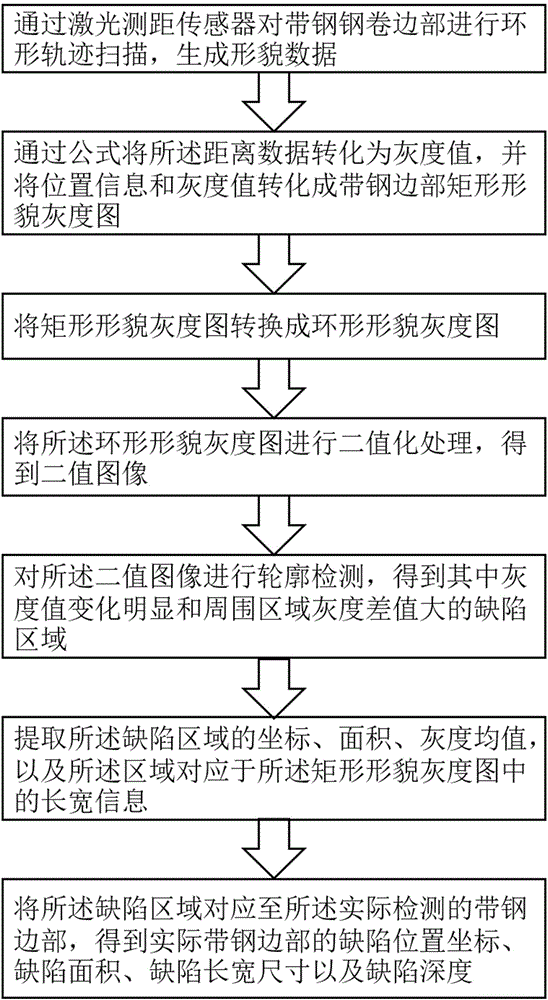

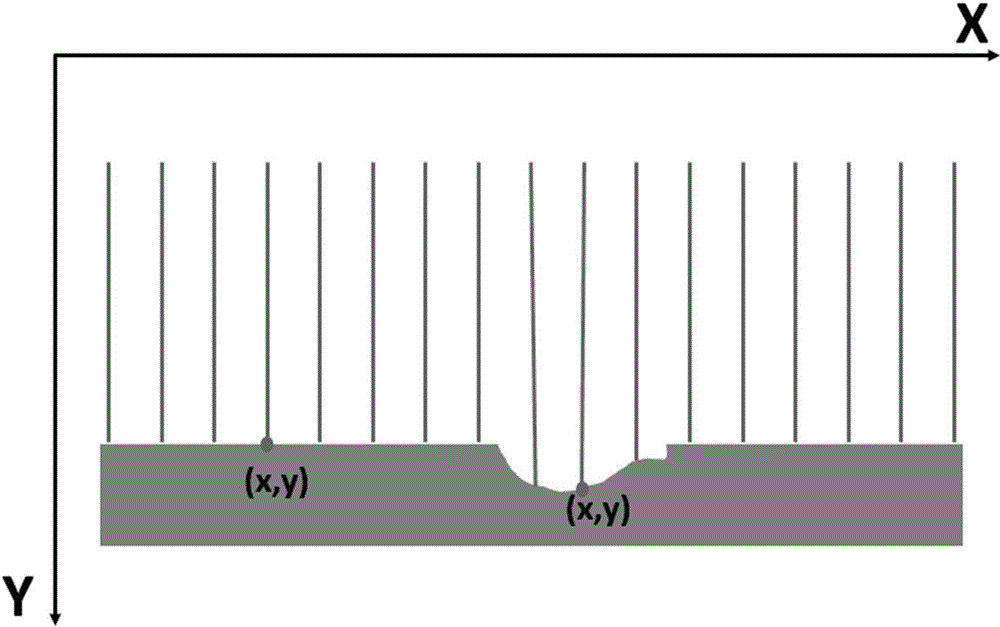

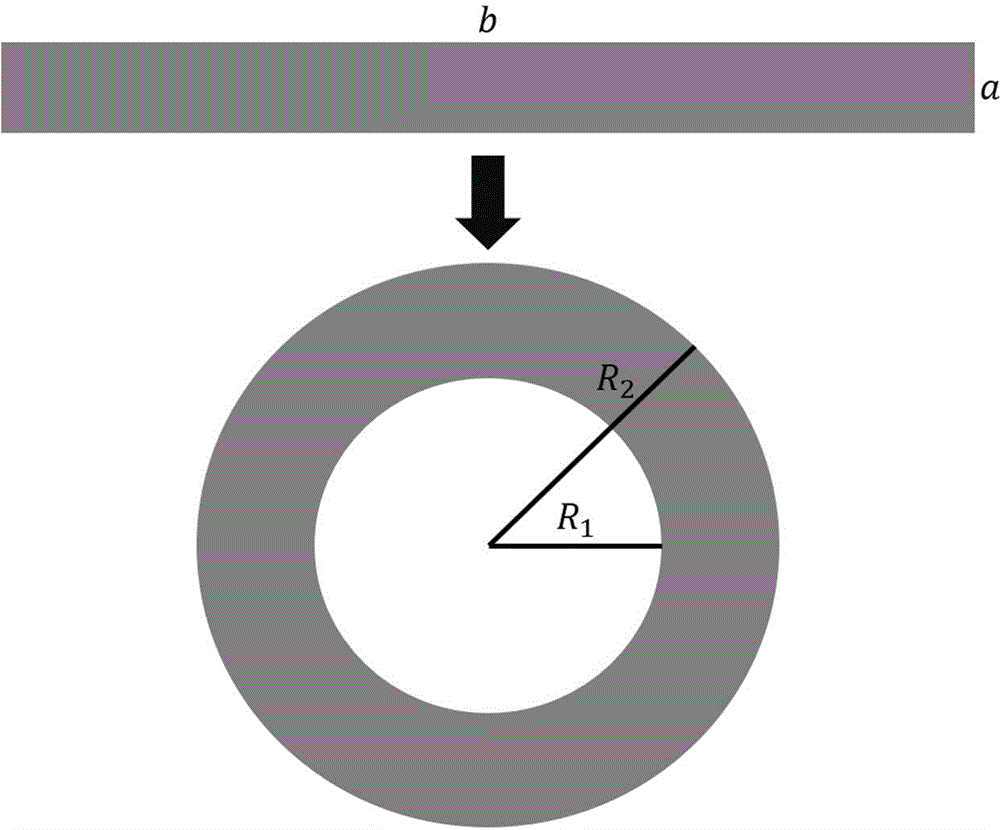

[0034] See attached figure 1 , the strip edge defect detection and identification method of the present invention comprises the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com