Fuel cell stack fixed structure convenient for adjustment

A technology for fuel cell stacks and fixed structures, which is applied in the direction of fuel cells, fuel cell groups, fuel cell components, etc. It can solve the problems that the stack cannot be guaranteed to be uniformly stressed, the fixing effect cannot be guaranteed, and the screws are easy to loosen, etc. , to achieve the effect of eliminating loosening, solving loosening and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

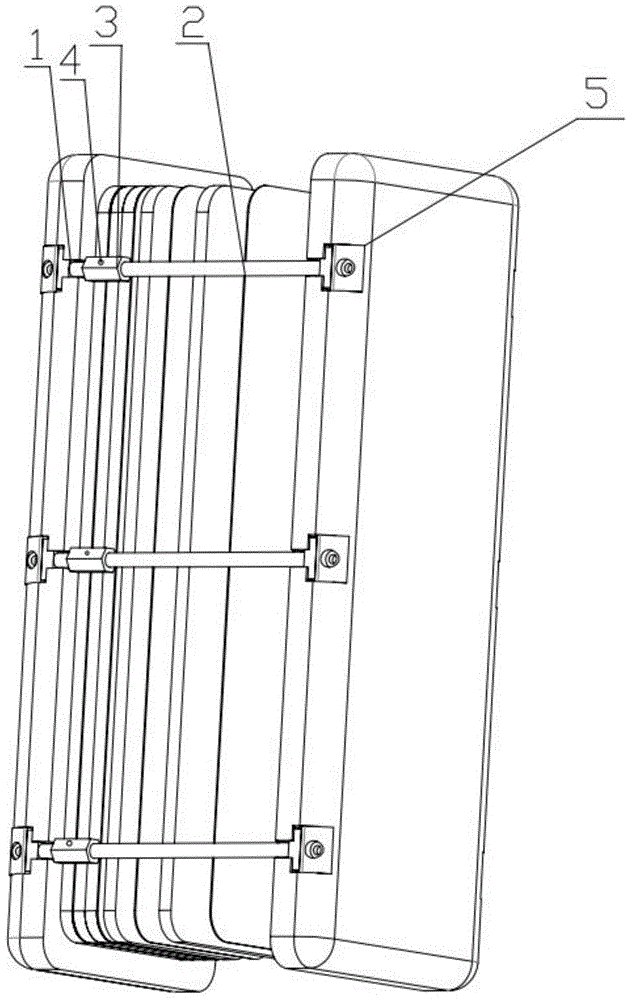

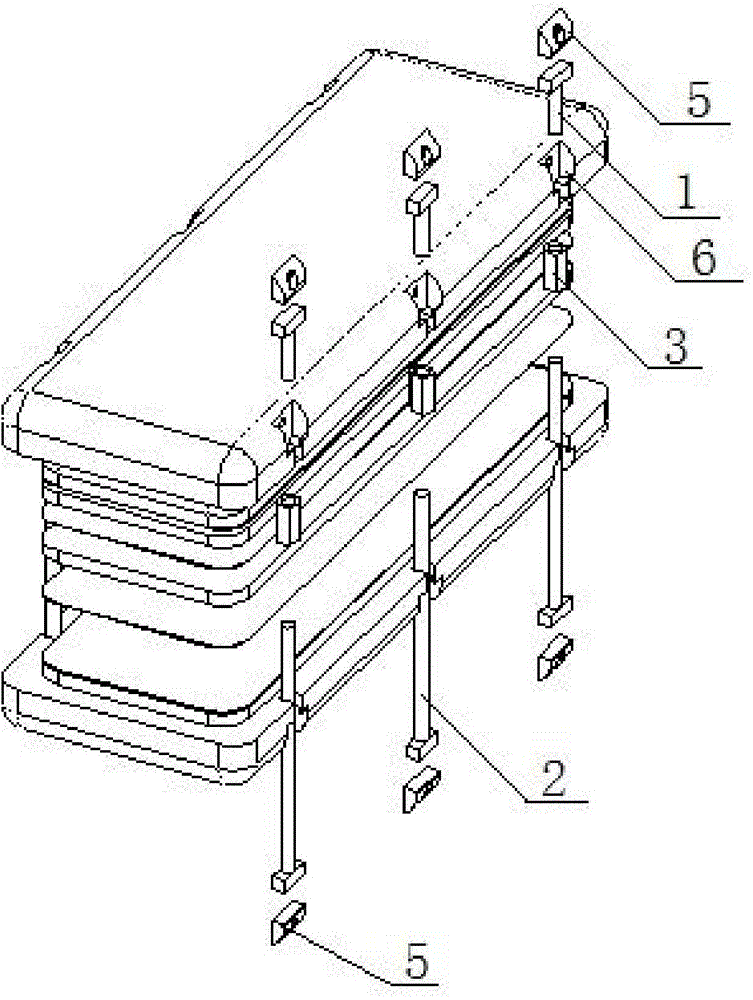

[0022] Example 1: Such as figure 1 , figure 2 The easy-to-adjust fuel cell stack fixing structure shown includes end plates arranged at both ends of the fuel cell stack in the stacking direction, and 6 sets of T-shaped screw rods 1, T-shaped screw rods 2, and connecting nuts 3 for fixing and connecting the end plates. , Set screw 4 and limit block 5, 6 groups are evenly distributed on both sides of the long side of the end plate, that is, there are 3 groups on the long side of each side, arranged in the upper, middle and lower.

[0023]T-shaped screw 1 and T-shaped screw 2 are made of stainless steel. The total thickness of the fuel cell stack is 520mm. The length of T-shaped screw 1 is 1 / 5 of the total thickness of the fuel cell stack. / 5. According to the number of fuel cells contained in the fuel cell stack, the selected T-shaped screw 1 and T-shaped screw 2 have a diameter of 5 mm and a thread of M5. The inner thread of the connecting nut is matched with T-shaped scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

| Wall thickness size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com