Fully-automatic tractor used for small cables

A fully automatic, traction machine technology, applied in the direction of cable laying equipment, etc., can solve the problems of unsafe construction personnel, unsatisfactory continuous construction, increased safety hazards, etc., to achieve work efficiency and cable penetration Stable and smooth laying, improving the effect of continuous construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

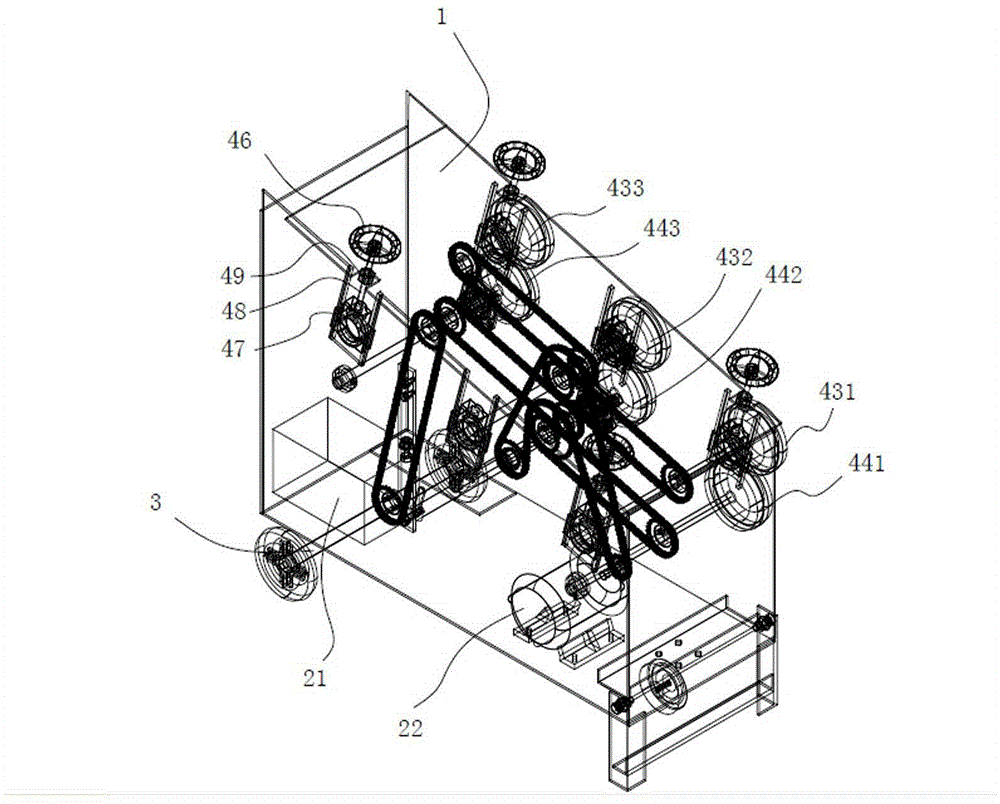

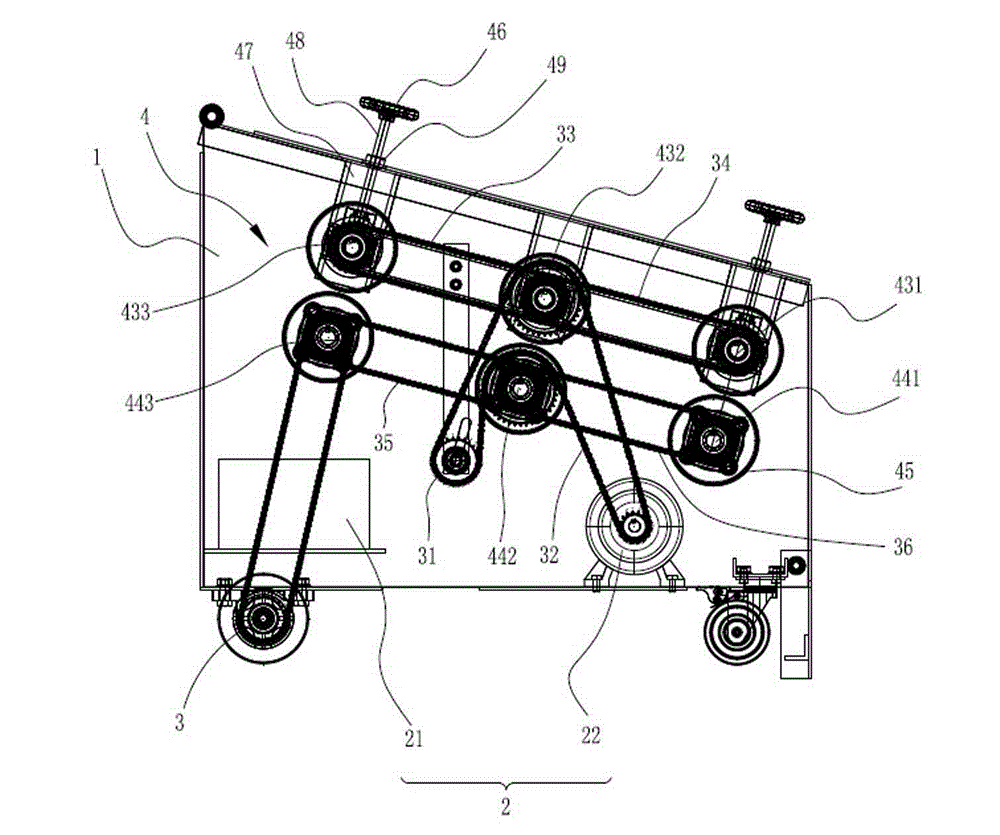

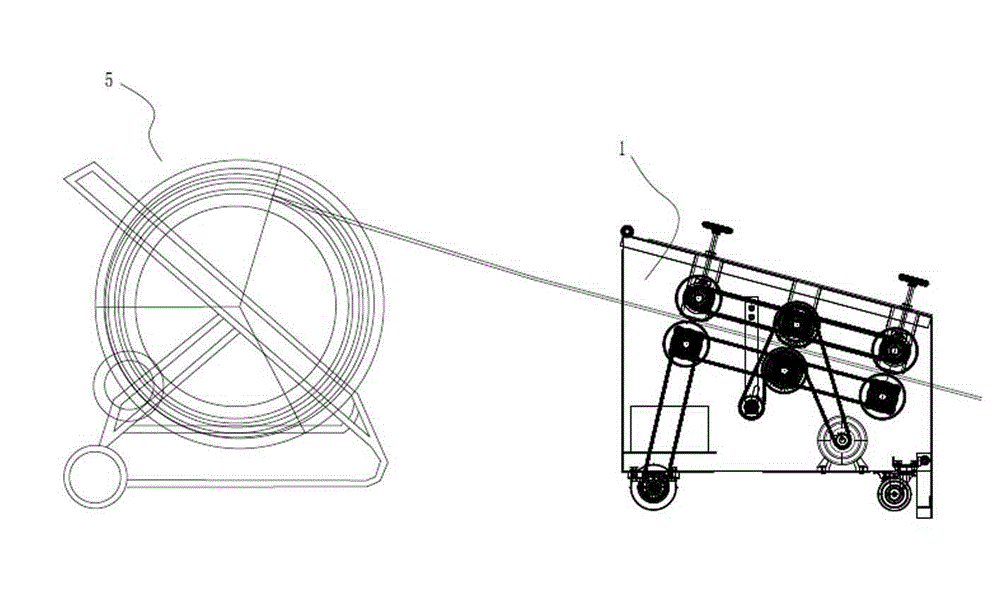

[0030] Such as Figure 1 to Figure 3 As shown, it is a fully automatic pulling machine for small cables disclosed by the present invention, which includes a frame 1, on which an electric drive mechanism 2, a transmission mechanism and a conveying mechanism 4 are arranged, and the electric drive mechanism 2 passes through a transmission The mechanism is connected to the conveying mechanism 4, and the conveying mechanism 4 has three groups. The conveying mechanism 4 includes an upper pressing wheel 41, a lower pressing wheel 42, an upper rotating shaft 43 and a lower rotating shaft 44, and the upper rotating shaft 43 and the lower rotating shaft 44 are all pivotally arranged on the frame 1 , the upper pinch roller 41 and the lower pinch roller 42 are installed on one side of the frame 1 by the upper rotating shaft 43 and the lower rotating shaft 44 respectively, a certain gap is spaced between the upper pinch roller 41 and the lower pinch roller 42 and the direction of rotation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com