vehicle pneumatic tires

A technology for pneumatic tires and vehicles, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., can solve the problems of limited wet characteristics and ice grip characteristics, and achieve good handling characteristics, simple implementation, The effect of good ice grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

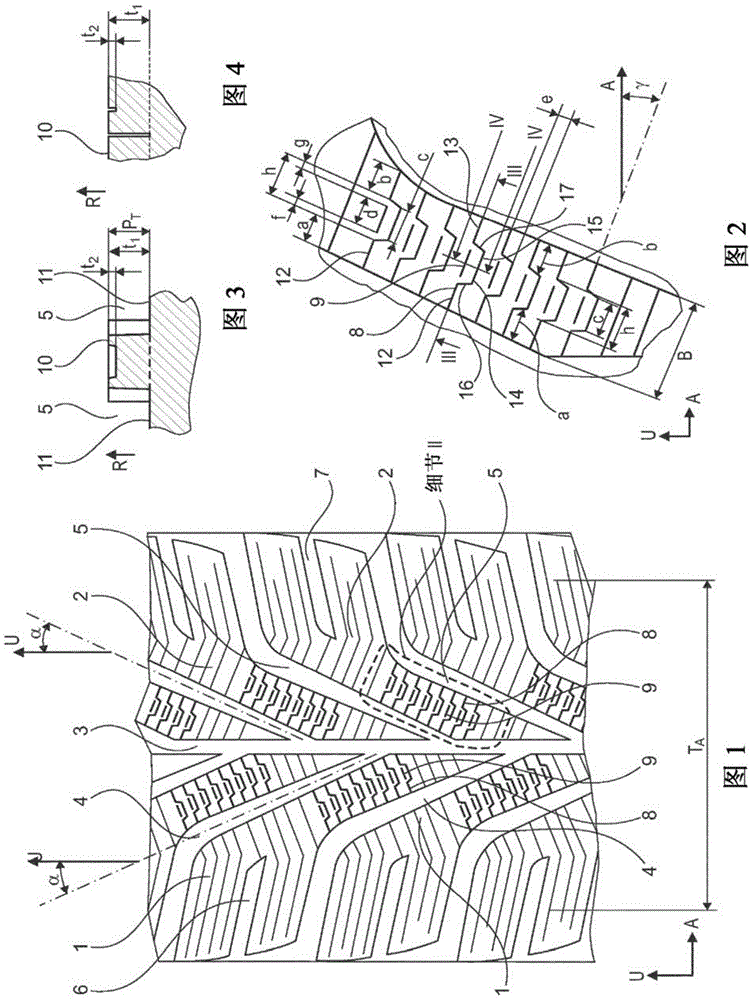

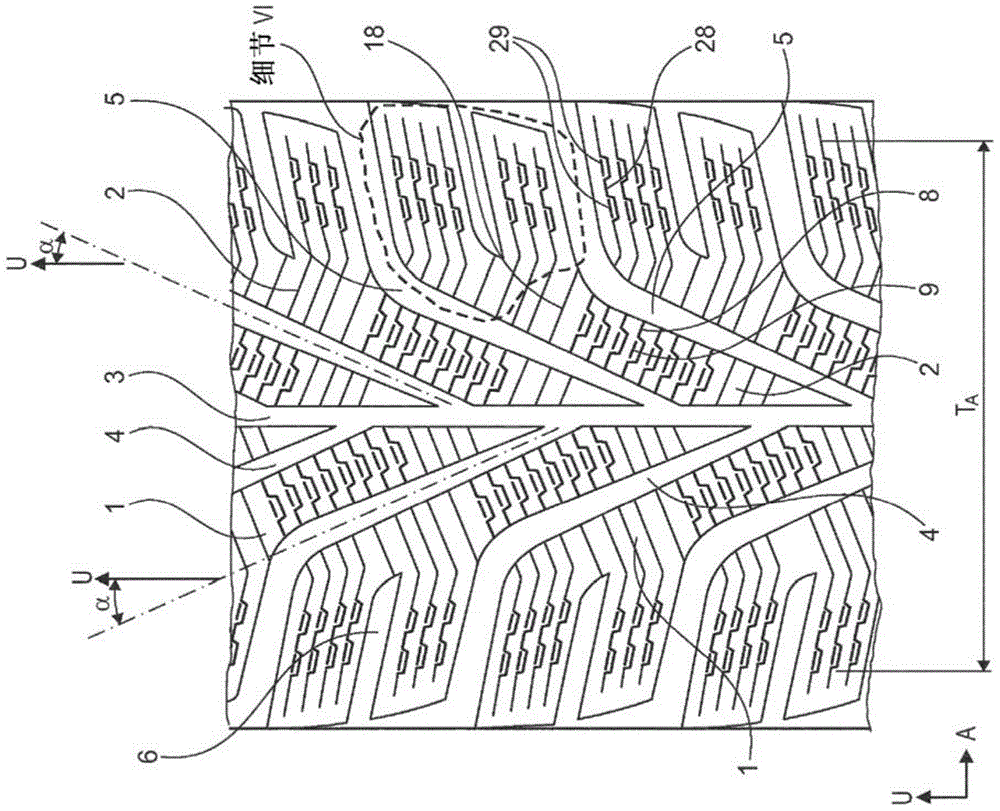

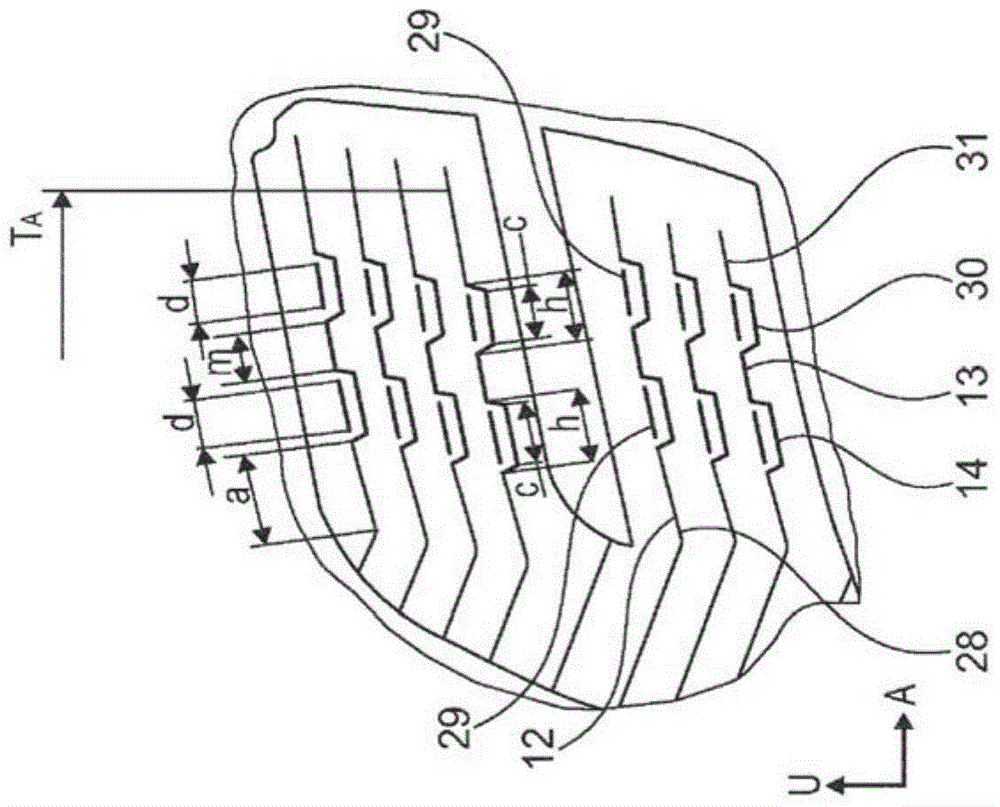

[0024] 1 to 4 show a tread pattern of a vehicle pneumatic tire for passenger cars (PKW), which has a tread pattern oriented in the circumferential direction U of the vehicle pneumatic tire and a central circumferential groove 3 extending circumferentially, which divides the tread pattern into two tread halves arranged adjacent to each other in the axial direction A of the vehicle pneumatic tire middle. The tread halves shown on the right in FIG. 1 are distributed over the circumference of the vehicle pneumatic tire and form rib-shaped, radially raised tread elements 2 of known type arranged one behind the other in the circumferential direction U , these tread elements each extend in the axial direction A starting from the circumferential groove 3 to a position in the right shoulder outside the bottom support surface width TA and stop there. The bottom bearing width TA is the width of the part of the tread in contact with the ground which complies with the E.T.R.T.O. interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com