Micro-hotplate device and sensor comprising such micro-hotplate device

A technology of micro-hot plate and gas sensor, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., and can solve problems such as non-existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

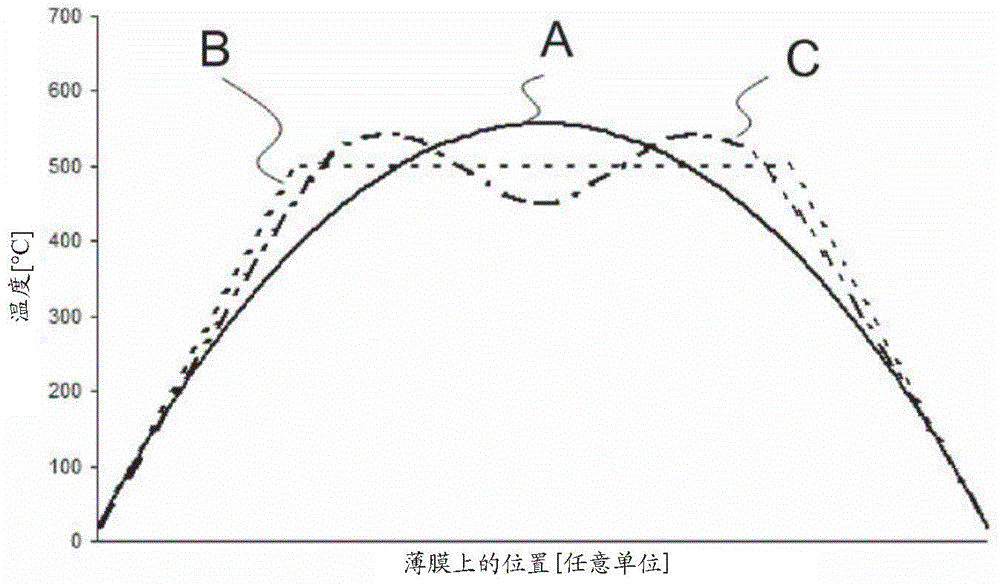

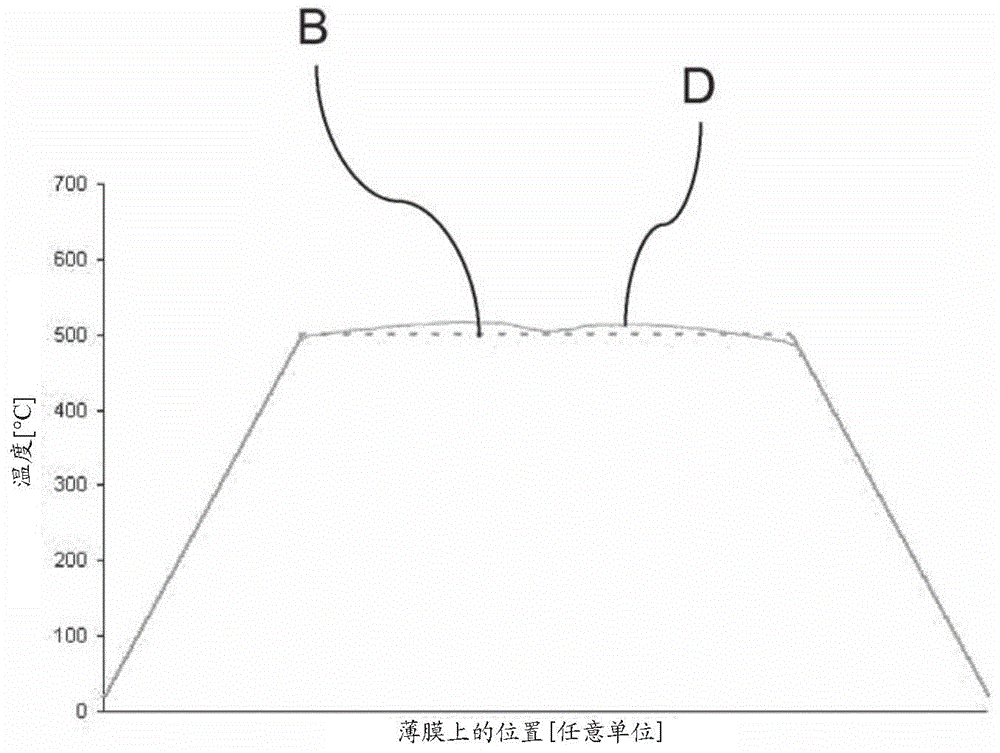

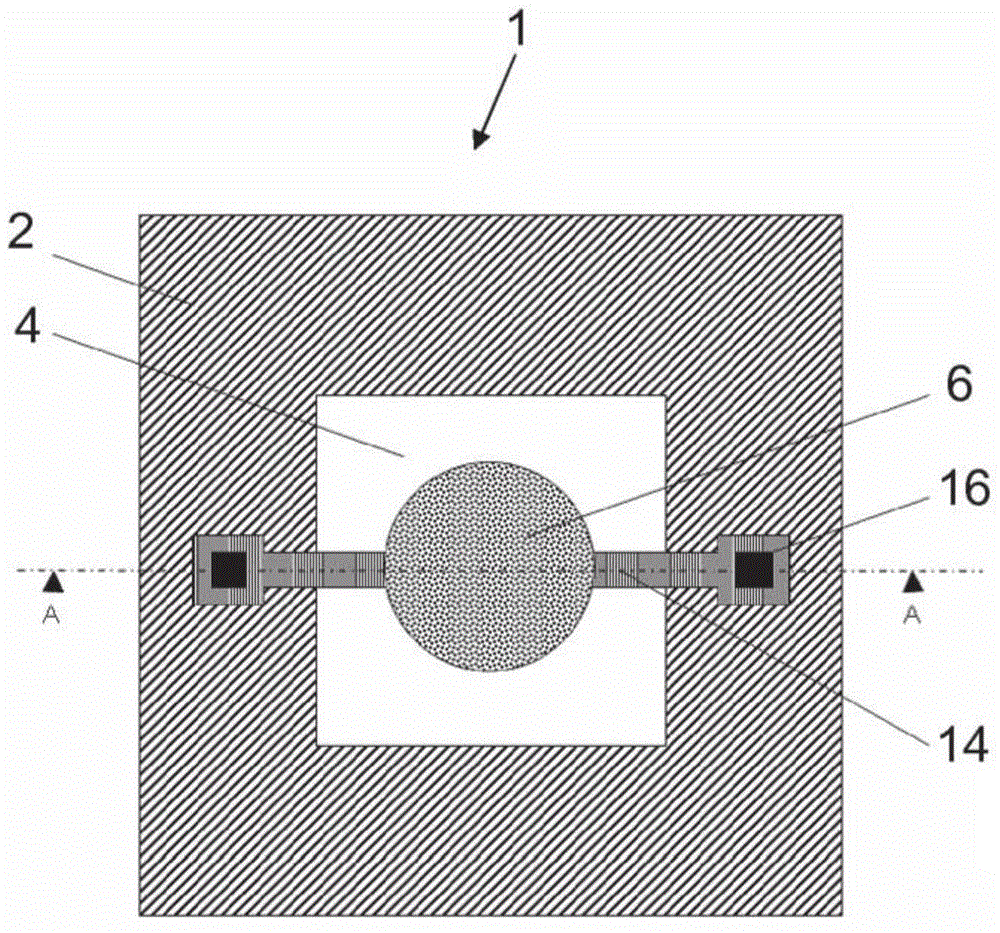

[0026] refer to figure 2 and image 3 , the micro-hot plate device 1 of the present invention comprises:

[0027] rigid frame 2;

[0028] a membrane 4 extending across said rigid frame 2;

[0029] an independent (ie not electrically connected) active region 6 comprising at least one active layer 8;

[0030] heating structures 10, deposited on the thin film 4 and designed to heat said active layer 8 to a given desired temperature;

[0031] a dielectric layer 12 for isolating the active layer from the heating structure; and

[0032] Contact tracks 14 and bonding pads 16 are used to connect the heating structure 10 .

[0033] The micro-hotplate is used for sensors, and more particularly for gas sensors. Depending on the sensor type, various combinations of passive and active layers can be deposited on the heating structure to achieve sensor functionality.

[0034] The lateral dimensions of the thin film 4 are generally in the range of 100 micrometers to several millimeter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com