Automatic control method used for defrosting a heat pump for a vehicle

a technology of automatic control and heat pump, which is applied in the direction of refrigeration components, transportation and packaging, light and heating equipment, etc., can solve the problems of reducing the efficiency of the heat pump, increasing the electricity consumption for the same performance level, and reducing the performance for the same level of electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0047]FIG. 5 is a flow diagram showing the main steps of the method of the invention,

[0048]FIG. 6 is a flow diagram showing the sub-steps of the defrosting operation of FIG. 5, and

second embodiment

[0049]FIG. 7 is a flow diagram showing the main steps of the method of the invention, and

third embodiment

[0050]FIG. 8 is a flow diagram showing the main steps of the method of the invention.

DETAILED DESCRIPTION OF AT LEAST ONE EMBODIMENT

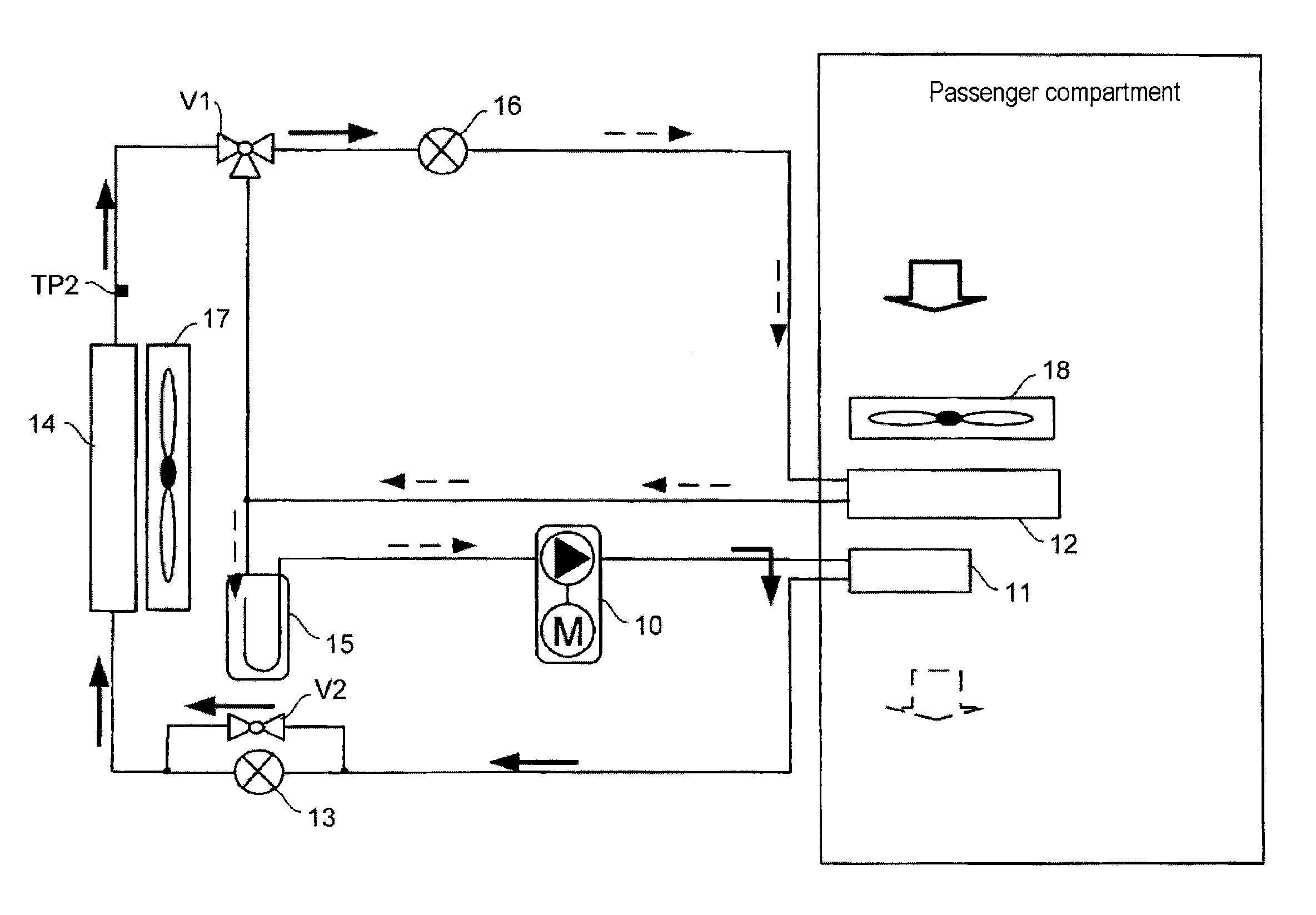

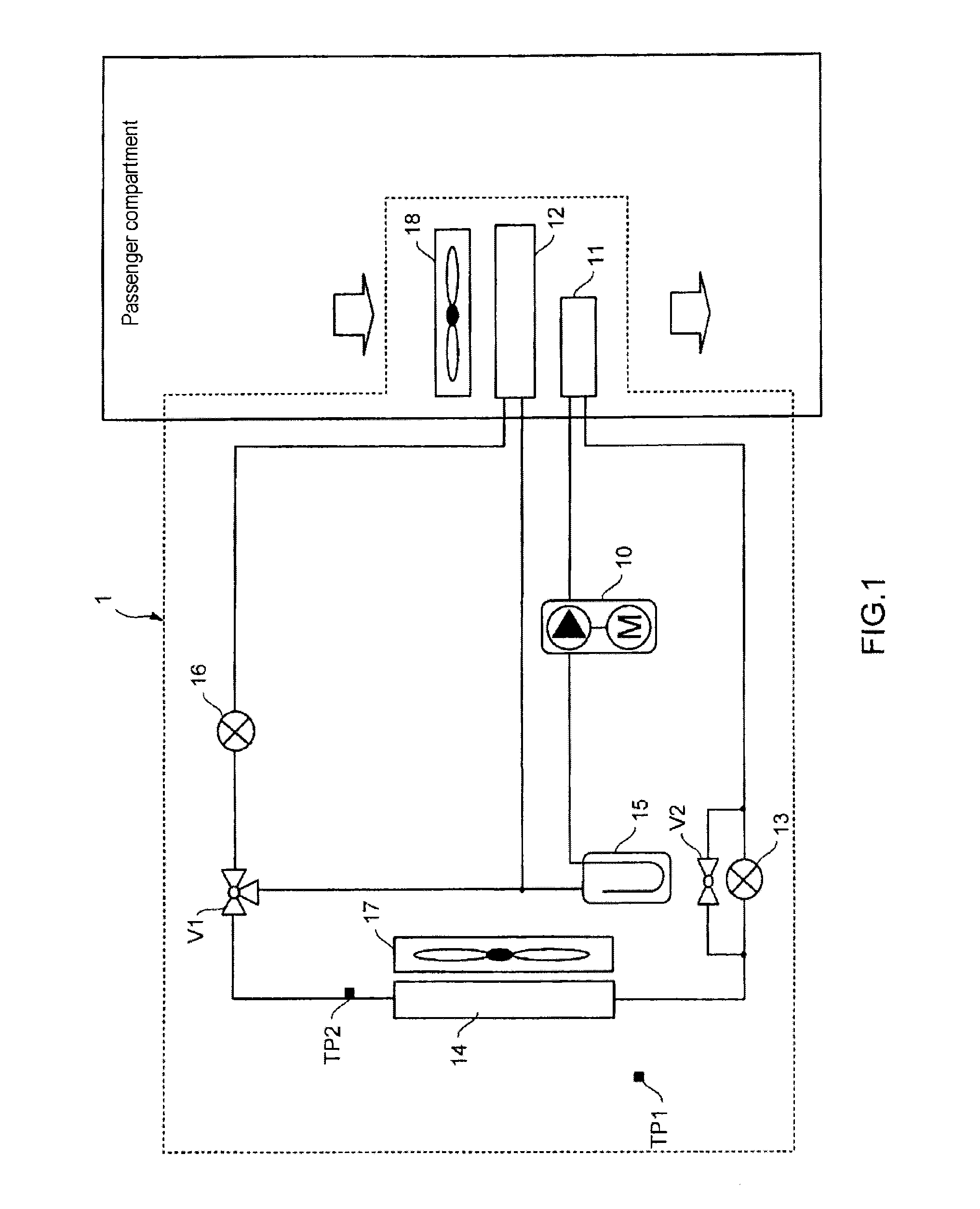

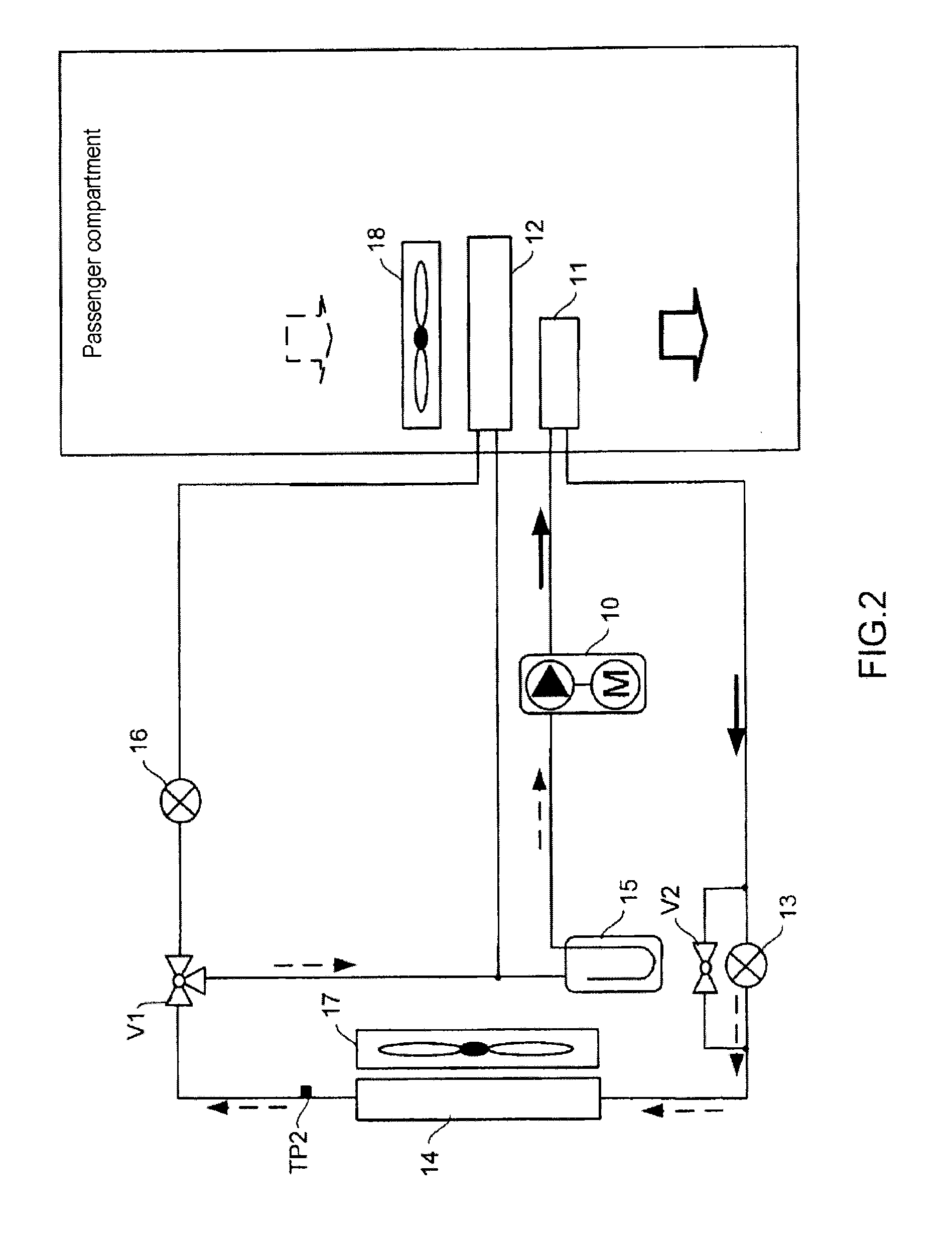

[0051]FIG. 1 shows a heat pump system 1 for which the method of the invention can be used. This system includes a compressor 10, an internal heat exchanger 11 forming an internal condenser in heating mode, another internal heat exchanger 12 forming an internal evaporator in air conditioning mode, an expansion valve 13 for the heating mode, an external heat exchanger 14 forming an evaporator in heating mode, an expansion valve 16 for the air conditioning mode, and an accumulator 15. These various components have a refrigerant fluid flowing through them. Valves V1 and V2 are also provided to modify the path of a refrigerant fluid through these various components according to one of the following operating modes of the system:[0052]in heating mode, the system heats the internal air of the passenger compartment of the vehicle; this operating mode is shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com