Digital die-free sand mold extrusion forming machine

A technology of extrusion molding and forming machines, applied in molding machines, casting molding equipment, metal processing equipment, etc., can solve problems such as cost increase, achieve cost saving, save time for replacing the overall mold, and shorten the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

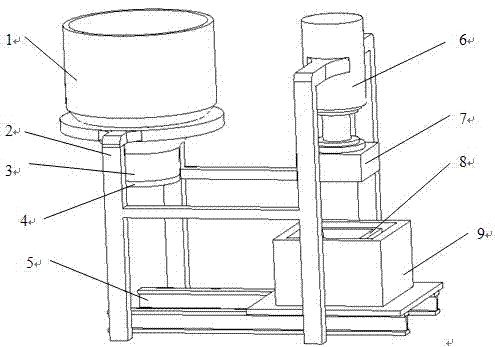

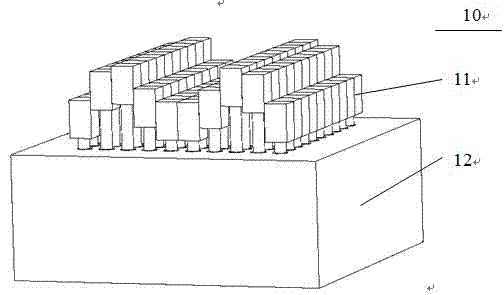

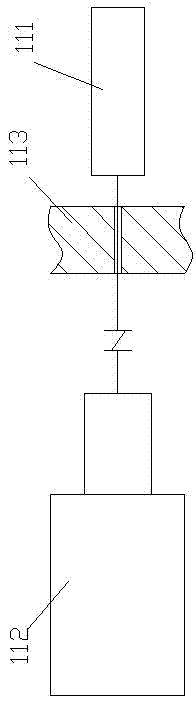

[0030] See attached figure 1 , 2 , The digital moldless sand extrusion molding machine of the present invention includes a molding machine support (2), an extrusion molding workbench and a pressing plate (7). The pressing plate is controlled by a motor (6), which can be lifted and lowered. The motor (6) is fixed on the bracket (2), and the pressing plate (7) is connected under the motor (6); the extrusion forming workbench includes Auxiliary box (9), sand box (8), extrusion platform (10), the auxiliary box (9) is installed on the guide rail (5) and can slide along the guide rail (5); the extrusion platform ( 10) It includes an extrusion array (11) and a control box (12), the bottom of the extrusion array (11) is installed in the control box (12); the sand box (8) is installed in the auxiliary box (9 ) bottom, a complete sand box is formed with the extrusion platform (10) as the bottom of the box.

[0031] The digital moldless sand extrusion molding machine of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com