Ground glass flange filter

A technology of filter and grinding mouth, which is applied in the direction of gravity filter, etc., can solve the problems that cannot be directly measured, and the shape of the sediment is irregular, and achieve the effect of convenient disassembly, uniform thickness and tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

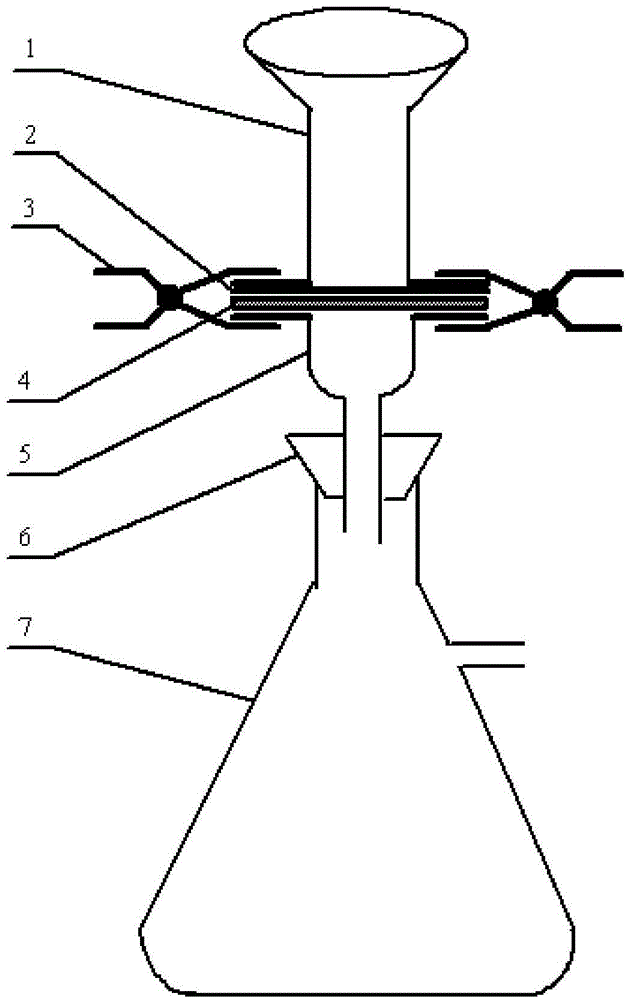

[0019] Such as figure 1 Shown is a ground glass flange filter of the present invention, the ground glass flange filter includes a ground feed liquid flange 1 and a ground support flange 5, a ground feed liquid flange 1 and a ground support method The flange 5 is docked; between the grinding mouth liquid flange 1 and the grinding mouth support flange 5, there is a perforated organic glass disc 4; between the grinding mouth liquid flange 1 and the perforated organic glass disc 4 Round filter paper 2.

[0020] Thus, the present invention adopts butted ground glass flanges and a perforated plexiglass disc between the two flanges to ensure that the thickness of the precipitated sample after filtration is uniform, and the precipitated sample on the filter paper sheet can be directly filtered after filtration. It can measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com