A Simple and Efficient Wet Magnetic Separation Method

A magnetic separation and wet technology, applied in wet separation, chemical instruments and methods, magnetic separation, etc., can solve the problems of uneven axial slurry flow distribution, long axial length of the tank body, and difficult magnetic separation process. Achieve the effect of solving the problem of magnetic mass inclusion, convenient feeding and unloading, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

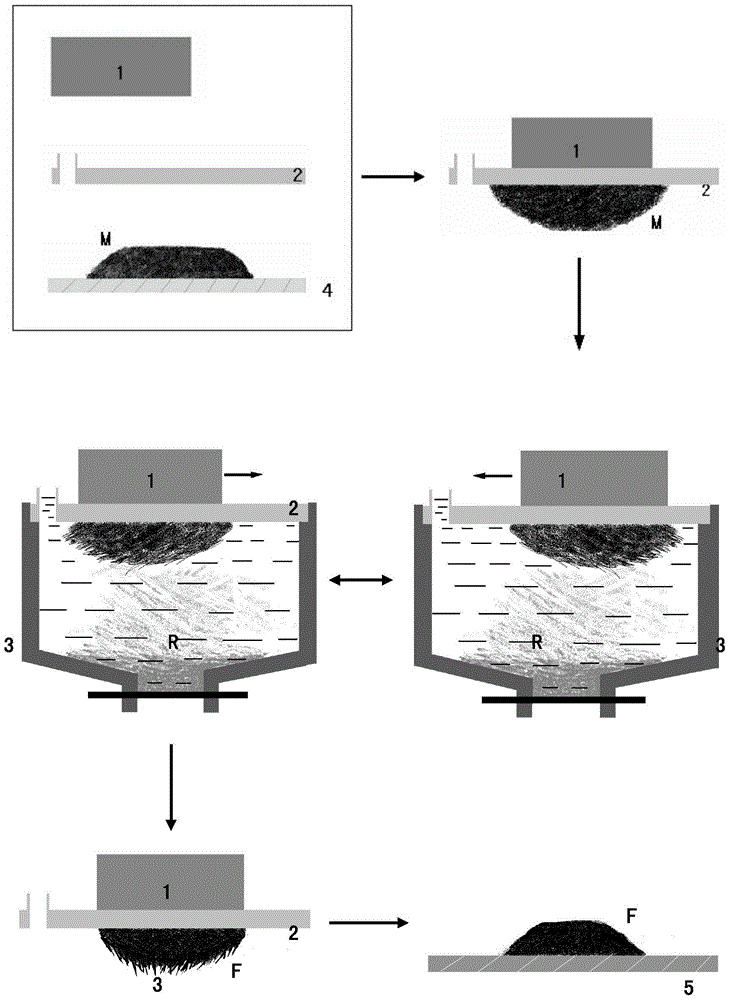

[0030] like figure 1As shown, a simple and high-efficiency wet magnetic separation method for ore powder with a tailings discharge port at the bottom of the tailings receiver. The ore powder to be separated is 49.58% iron, including magnetic iron and hematite, with a particle size of 75 μm The following accounts for 80% of iron ore.

[0031] The glass partition 2 is equipped with a liquid level port; the tailings receiver 3 is a wide-mouth plexiglass container with a groove on the upper end. The magnetic induction intensity generated by the magnet is 180mT-270mT when there is no water on the other side of the partition. Before sorting, use the magnet 1 to suck the iron ore powder M to be separated from the raw material carrier plate 4 through the partition 2, and then move the magnet 1, the partition 2 and the iron ore powder M to the tailings receiver 3 as a whole Fix the partition on the tailings receiver 3, add water from the liquid level port until the liquid level of th...

Embodiment 2

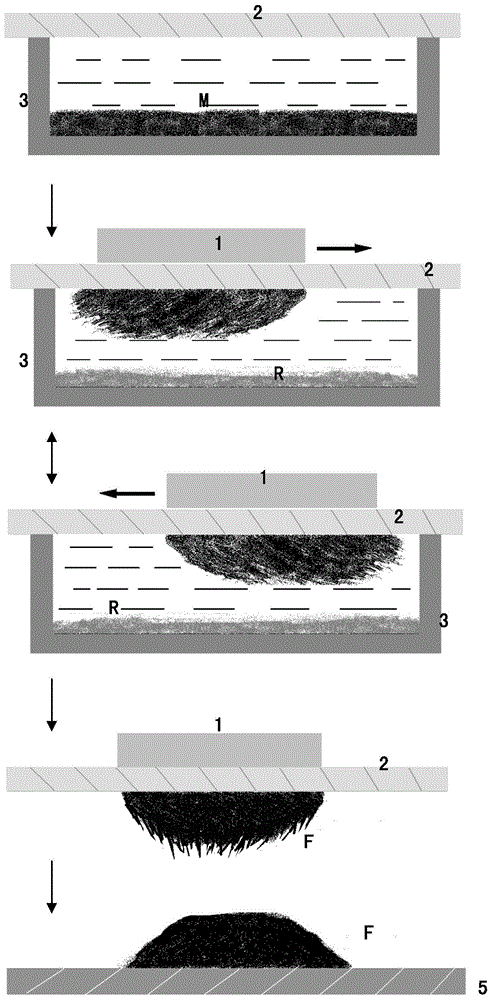

[0033] like figure 2 As shown, a simple high-efficiency wet magnetic separation ore powder method using a wide-mouth flat-bottomed tank as a tailings receiver. The ore powder to be selected is 30.81% iron grade, including magnetic iron, false hematite, hematite , 75% of the low-grade iron ore has a particle size below 75 μm.

[0034] The tailings receiver 3 is a glass wide-mouth flat-bottom tank with a height of 18mm. The magnetic induction intensity generated by the magnet 1 is 180-270mT when there is no water on the other side of the glass partition. Put the iron ore powder M in the tailings receiver 3, fill it with water, cover the glass partition 2, place the magnet 1 on the partition 2, form a magnetopolymer and sort it, and use the magnet for cleaning during the sorting process 1. Suction the concentrate F through the partition 2 and separate it from the tailings receiver 3. After the tailings slurry is discharged into the tailings pond, rinse with ring water and fill ...

Embodiment 3

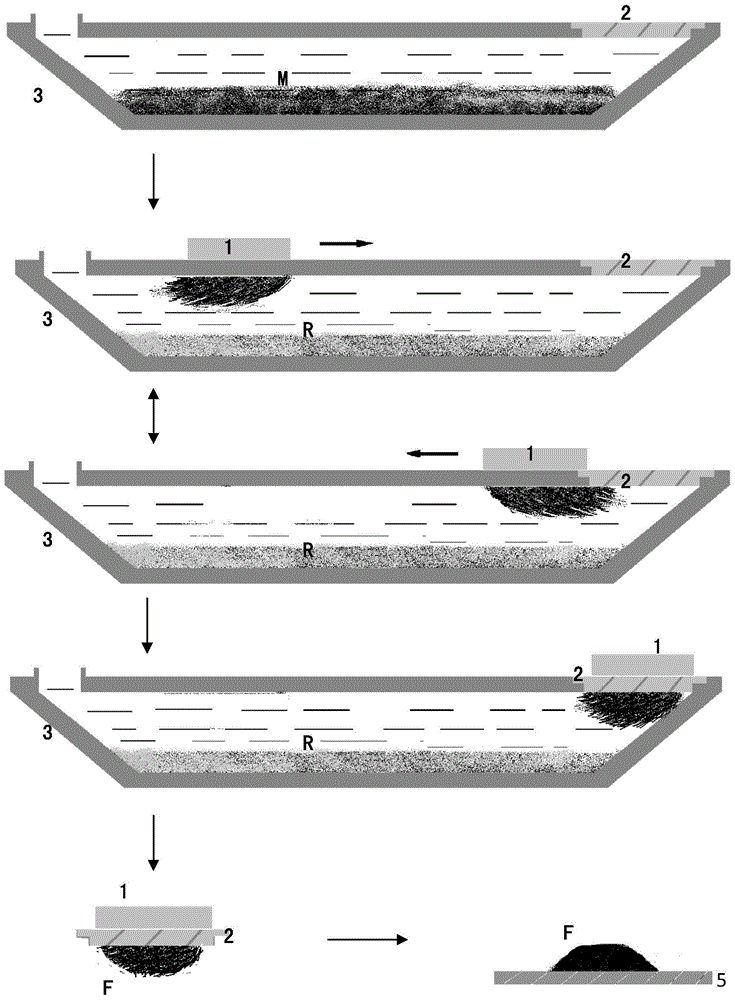

[0036] like image 3 Shown, a kind of method of simple and efficient wet magnetic separation slurry with container wall as partition, the ore powder to be separated is iron grade 43.43%, including magnetic iron, hematite, and the iron ore whose grain size is below 75 μm accounts for 86%.

[0037] The tailings receiver 3 is a plexiglass flat-bottomed container with a liquid level port and a concentrate outlet on the top. The upper container wall of the tailings receiver 3 acts as a partition, and the plexiglass partition 2 is used for suction after sorting. Reserve and transfer the concentrate, the height of the sorting space is 23mm, and the magnetic induction intensity generated by the magnet is 190-300mT when there is no water on the other side of the partition. Fill the tailings receiver 3 with the slurry to be selected, fix the partition 2 on the tailings receiver 3, place the magnet 1 on the area of the tailings receiver 3 that acts as a partition, and form a magnetopol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com