Single tube self-absorption type particle spray gun nozzle

A self-priming, particle technology, used in coatings, devices for coating liquids on surfaces, etc., can solve the problems of inability to achieve mechanization, many basic theoretical studies, and low utilization of fillers, so as to improve the spraying effect and quickly repair. The level of the application, the expansion of the application field, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

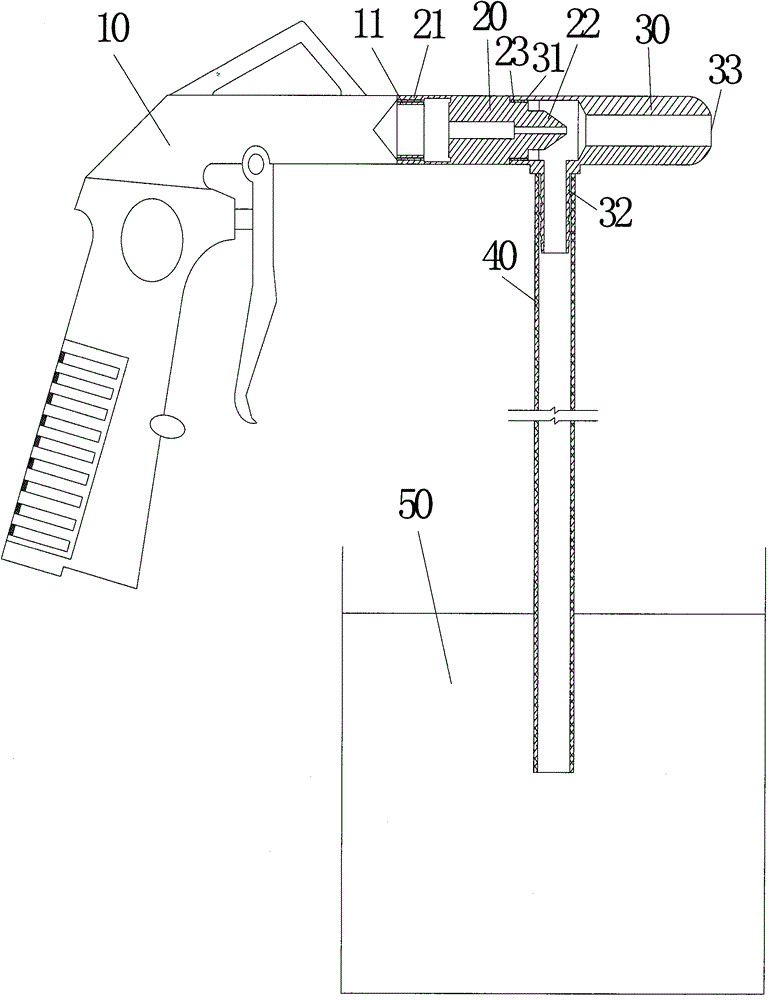

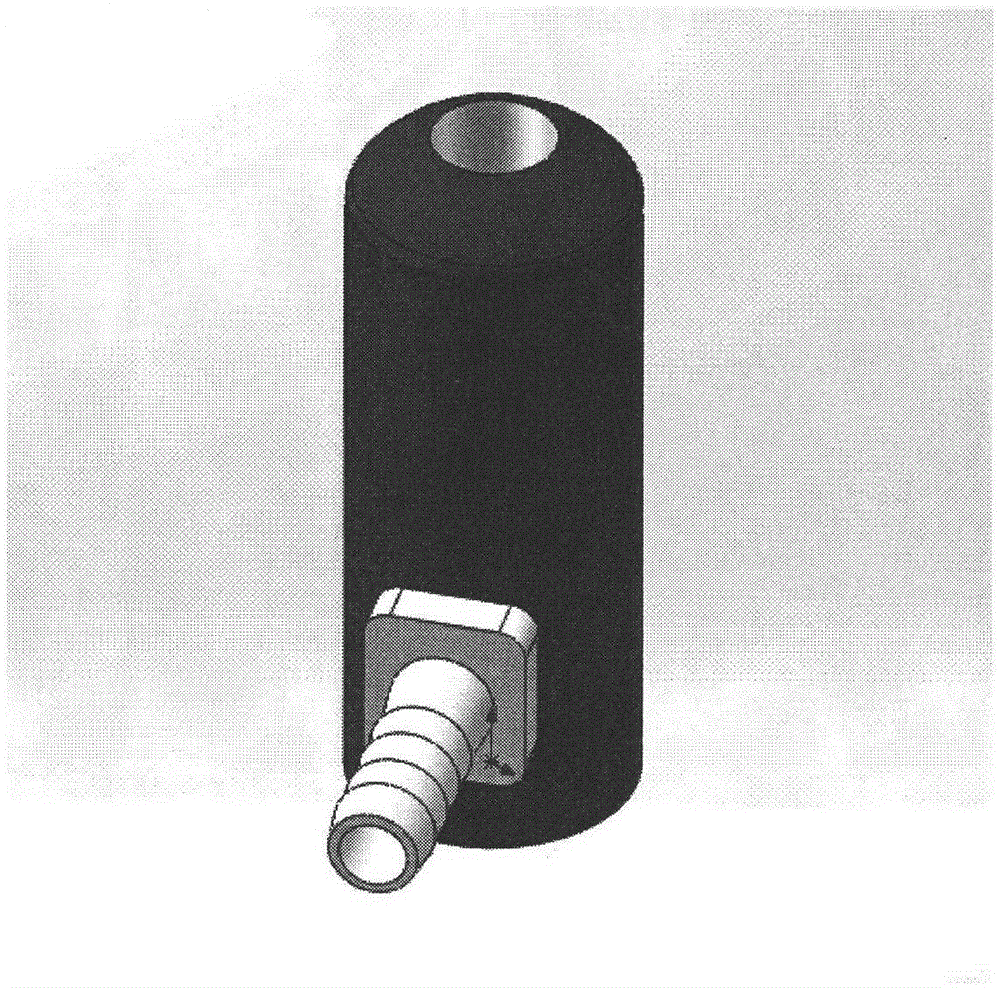

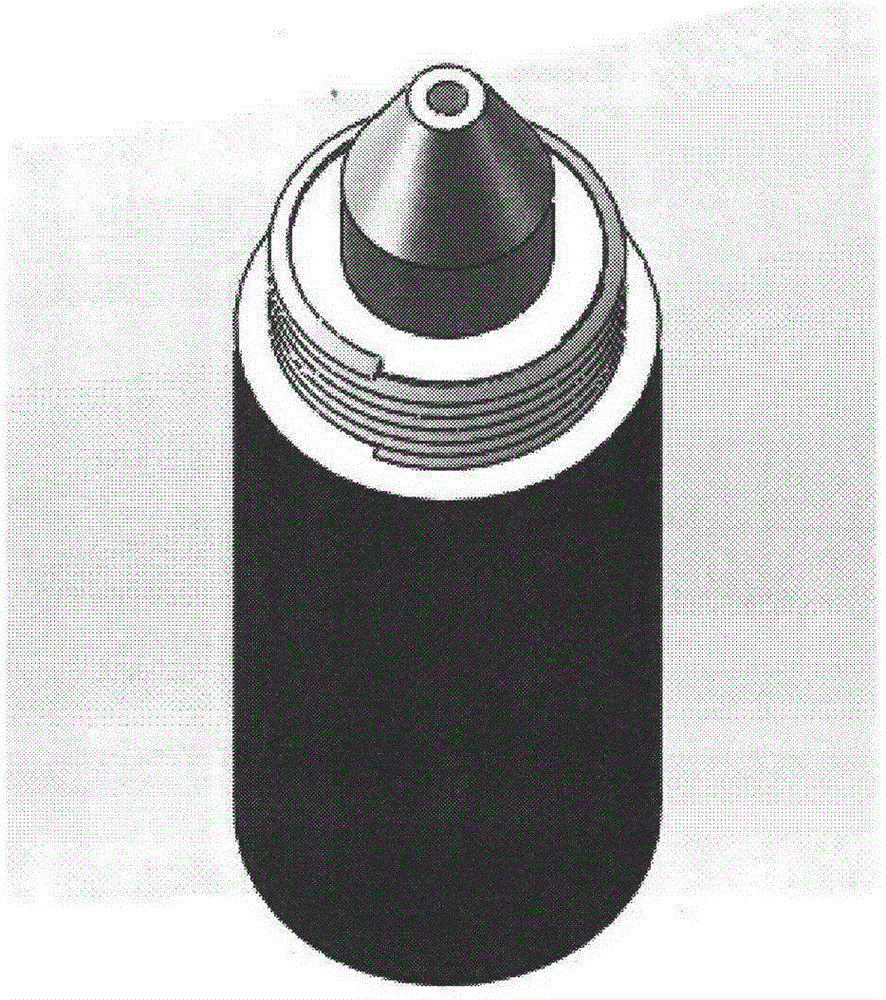

[0021] figure 1 It is a combined sectional view of the present invention, which mainly includes a paint spray gun 10 that needs to be connected with an air compressor, and its head is provided with an external thread 11. Screw onto spray gun. The spray head mainly includes two parts, the jet joint 20 and the nozzle 30, and the elevation appearance of the jet joint is as follows: figure 2 As shown, the elevation appearance of the nozzle is shown in image 3 shown. One end of the spray joint 20 has an internal screw hole 21 and the spray gun thread 11 to be screwed, and the other end is provided with a through air hole 22. The front end is conical, and an external thread 23 is arranged at the root of the conical air hole. The inner screw hole 31 is screwed to connect the nozzle for spraying solid particles to the spray head. A pipe joint 32 extending downward is provided on the nozzle, and the pipe joint is socketed with the supply rubber hose body 40, and the rubber hose b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com