sorting device for logistics

A sorting device and logistics technology, applied in grading, solid separation, sending objects, etc., can solve the problems of complex structure, reduced work efficiency, trouble, etc. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

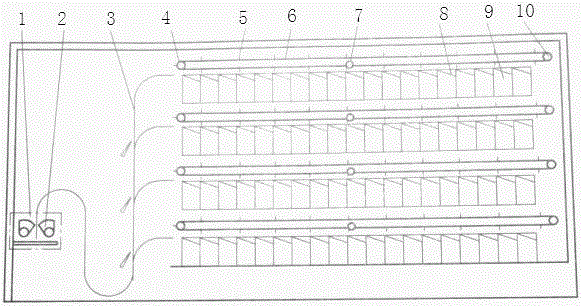

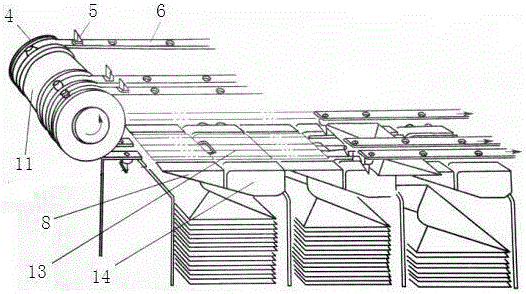

[0016] see figure 1 , figure 2 , a sorting device for logistics, the sorting device includes a steering mechanism 1, a sector wheel 2, a rotary layer 3, a driving wheel 4, a synchronous hole belt 6, a splitter 8, a hull 14, a slideway 13 and The driven wheel 10, one end of the steering mechanism 1 is connected to the sector wheel 2, and the other end is connected to the rotary layer 3, the driving wheel 4 drives the synchronous hole belt 6, and the hull 14 is arranged between the driving wheel 4 and the driven wheel 10 Between, the hull 14 is provided with a slideway 13 and a splitter 8 . The entire equipment has a compact structure, and through the mutual cooperation of the driving wheel, driven wheel, hull, and synchronous hole belt of the splitter, orderly movement on the slideway is ensured, constant speed ratio is achieved, meshing conveying includes entry, and the sorting is completed quickly and orderly. Pick a job.

Embodiment 2

[0018] see figure 1 , figure 2 , as an improvement of the present invention, the sorting device further includes a push finger 5 , and the push finger 5 is fixed on the synchronous hole belt 6 . The push finger 5 is arranged on the synchronous hole belt 6 according to a certain distance, the push finger 5 is fixed on the synchronous hole belt 6 through the push finger support, and the push finger is arranged on the push finger support through a hinge pin or a torsion spring. On the seat, it can be turned up along the direction of the belt. When the package is jammed, the push finger will automatically turn up due to resistance, thus playing a protective role. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0020] see figure 1 , figure 2 , as an improvement of the present invention, the sorting device further includes a dragging mechanism 7, and the dragging mechanism 7 is arranged on the synchronous hole belt 6. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com