Pre-warning system and pre-warning method for inclination of temper mill

A kind of early warning system and technology of tempering machine, which is applied in the field of tempering machine, can solve problems such as the inclination of the tempering machine, and achieve the effect of reducing broken belts, avoiding losses, and speeding up the early warning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

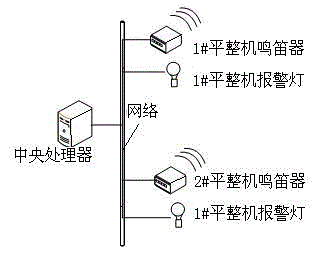

[0027] See figure 1 , an early warning system for the inclination of the temper mill, which includes a central processor 1 responsible for the analysis and prediction of the inclination of the temper mill, and the central processor simultaneously monitors the rolling force of the driving side of the roll and the rolling force of the operating side and the driving side and operation of the roll It also includes the alarm lamp 2 and whistler 3 controlled by the central processor. There are two groups of alarm lamps and whistlers, which are respectively located on both sides between No. 1 and No. 2 leveling machines and Set close to the strip walking position.

[0028] The early warning method of the slope early warning system of the grader comprises:

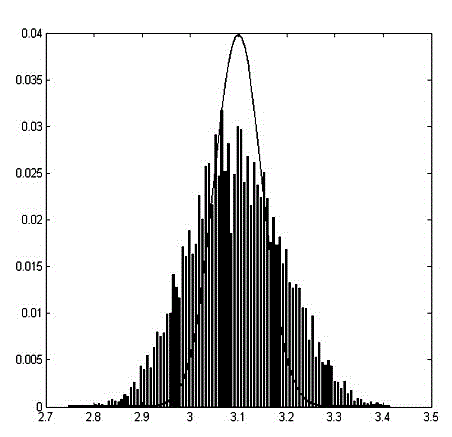

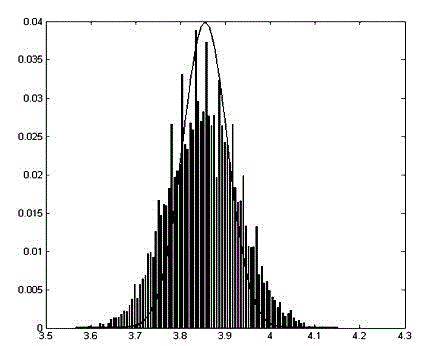

[0029] Step 1, the central processing unit analyzes the inclination of the temper mill, including extracting the following production rules to judge the occurrence of roll inclination faults. In order to reduce false positives, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com