Multi-male-die one-time extrusion forming method for spatial bending pipe

A technology for extrusion molding and bending pipes, which is applied in the field of multi-convex extrusion molding space bending pipes, which can solve the problems of not being able to prepare space bending pipes at one time, limited bending angle and direction of pipes, and wrinkled cross-sections, etc., to reach the surface The effect of good quality, good quality and smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

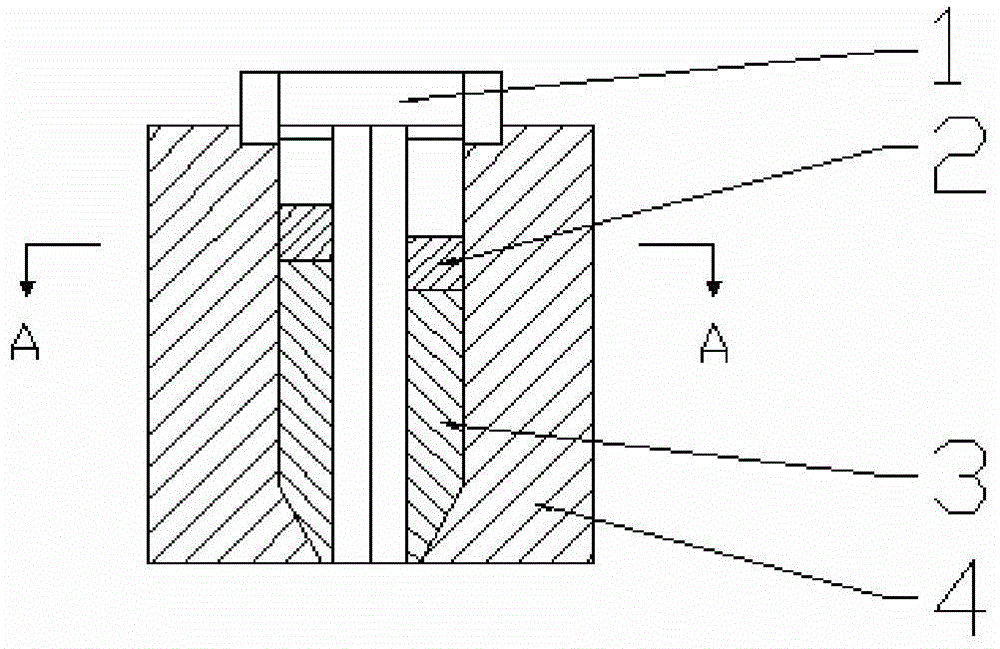

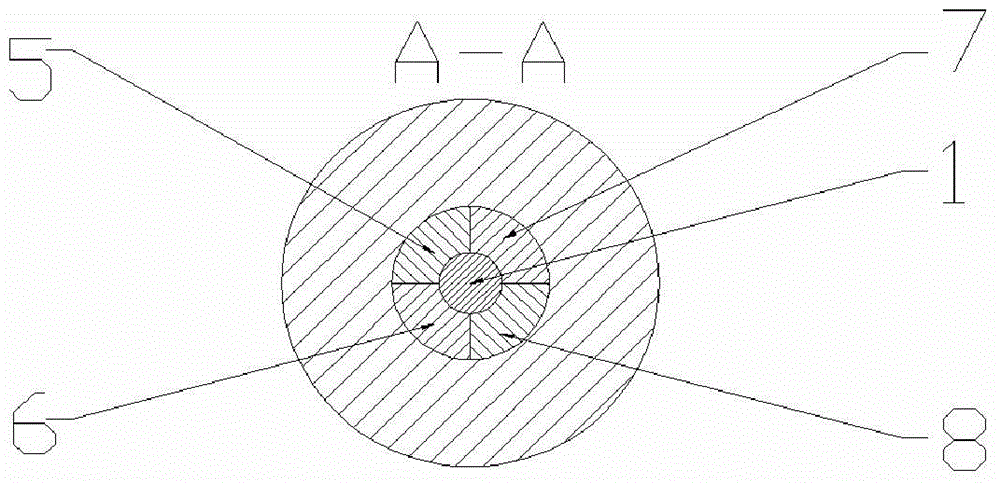

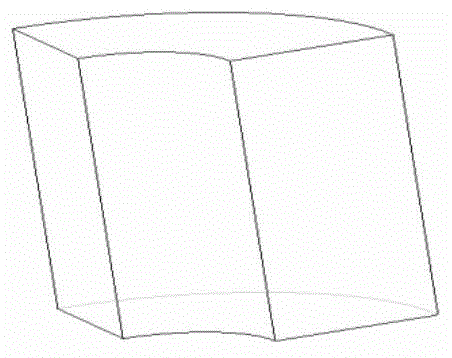

[0030] See attached figure 1 - attached Figure 6 , (1) In this embodiment, the blank 3 is a concentric aluminum alloy 1100 tube blank, and there is a central hole in the middle of the blank, which is convenient for the mandrel to pass through. The taper of the discharge end of the die is 59°, the height is 20mm, and the extrusion billet temperature is 300°C. The inner diameter of the elbow is 20mm, the wall thickness is 3mm, and the bending direction is unidirectional.

[0031] (2) The working procedure of the present embodiment is: the blank 3 is placed in the die 4, and then four punches 5, 6, 7, and 8 are put into the die 4 respectively, and the mandrel The upper end of 1 is fixed on the die 4 through a beam, the middle part of mandrel 1 is in contact with each punch and blank 3 according to zero-gap fit, and the lower end of mandrel 1 passes through the exit ends of each punch, blank 3 and die 4. The pressure is applied to the four punches through four groups of hydrau...

Embodiment 2

[0034] See attached figure 1 - attached Figure 6 , (1) In this embodiment, the blank is 3 concentric aluminum alloy 1100 tube blanks, and there is a central hole in the middle of the blank, which is convenient for the mandrel to pass through. The taper of the discharge end of the die is 59°, the height is 20mm, and the extrusion billet temperature is 25°C. The inner diameter of the elbow is 20mm, the wall thickness is 3mm, and the bending direction is multi-directional.

[0035] (2) The working procedure of the present embodiment is: the blank 3 is placed in the die 4, and then four punches 5, 6, 7, and 8 are put into the die 4 respectively, and the mandrel The upper end of 1 is fixed on the die 4 through a beam, the middle part of mandrel 1 is in contact with each punch and blank 3 according to zero-gap fit, and the lower end of mandrel 1 passes through the exit ends of each punch, blank 3 and die 4. The pressure is applied to the four punches through four groups of hydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com