Anvil clamping device for hydraulic forging press

A technology of clamping device and hydraulic press, which is used in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc. The effect of replacement, easy installation, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

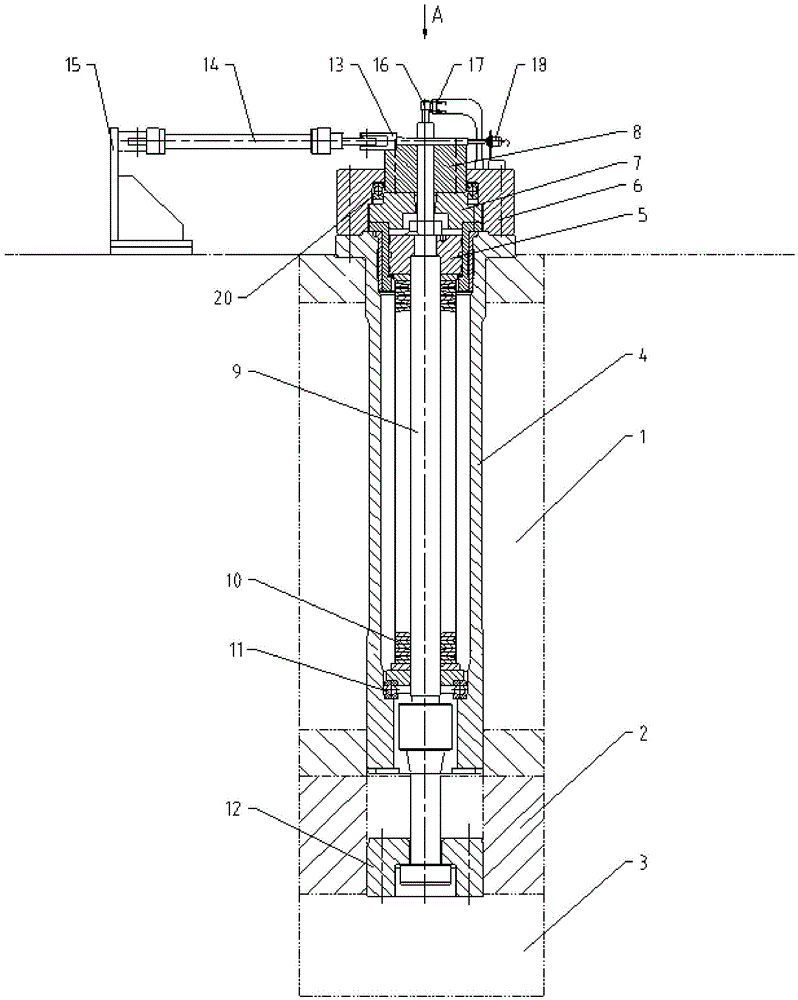

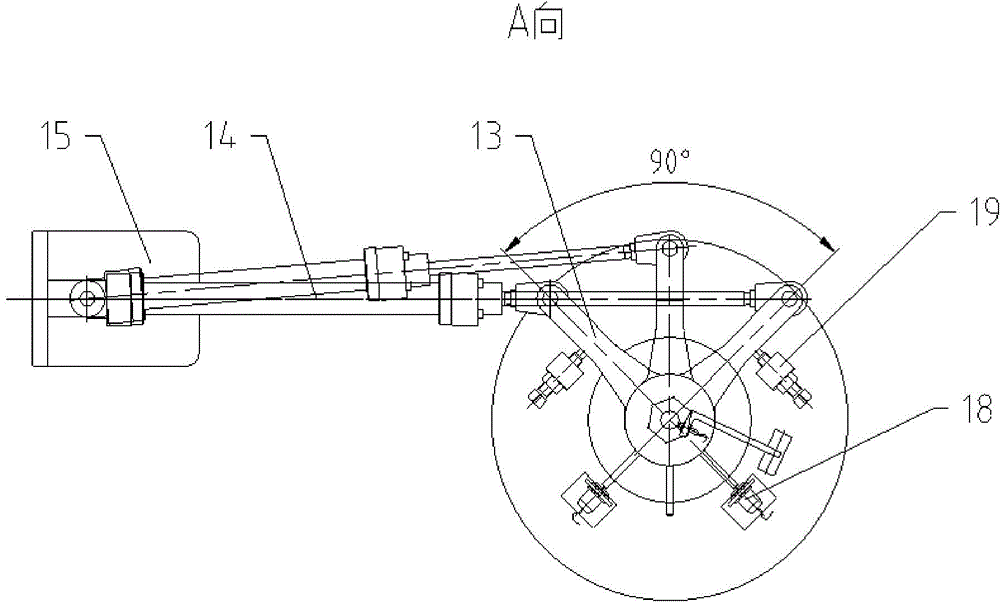

[0015] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, an upper anvil clamping device for a forging hydraulic press can realize quick replacement, rotation and clamping of the upper anvil during the operation of the forging hydraulic press. When the forging hydraulic machine is ready to work, fix the connecting block 12 on the upper anvil 3 and put it in place under the movable beam 1 of the hydraulic machine. The oil cylinder 4 is filled with hydraulic oil, and the piston 5 pushes the pull rod 9 to overcome the clamping force of the disc spring group 10 and move downward. , the pull rod 9 is a T-shaped structure. When the T-shaped head passes through the connecting block 12 and reaches the position, the proximity switch A17 sends a signal, and the oil cylinder 4 stops moving. After that, the hydraulic cylinder 14 pushes the connecting rod 13 to drive the rotating block 8 to rotate, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com