A double-ear wedge-shaped clamp for die-forged load-bearing cables

A technology of wedge-shaped wire clips and load-bearing cables, applied in the direction of overhead lines, can solve the problems of difficult casting defects, hidden hidden dangers in safe and reliable operation, complex workpiece structure, etc., to eliminate hidden safety hazards, improve manufacturability, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

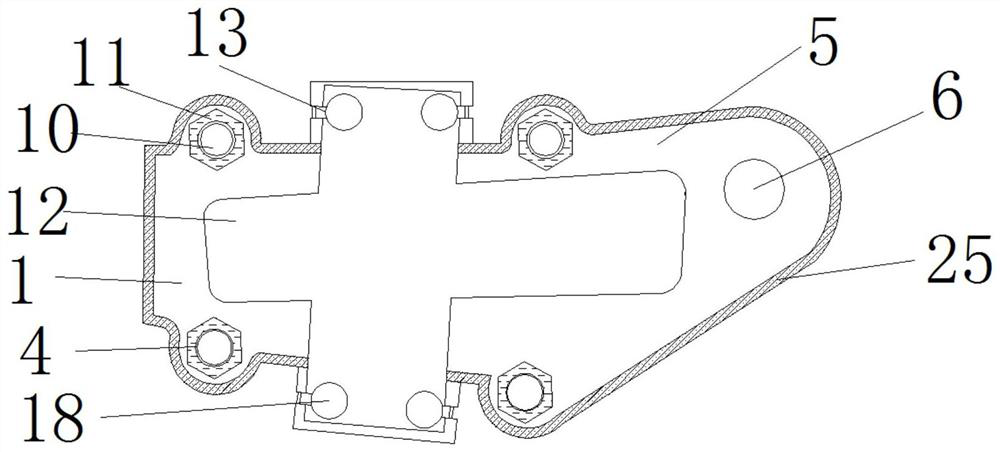

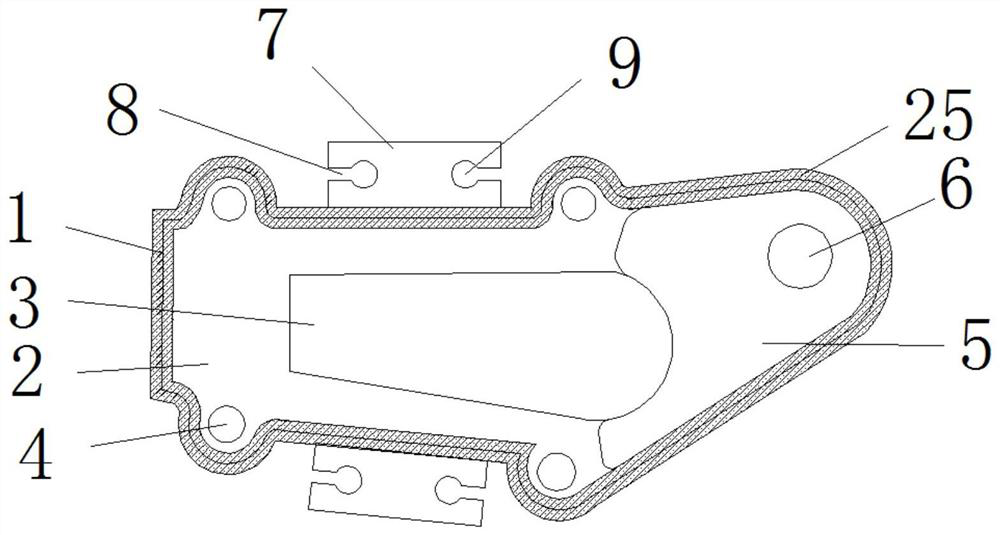

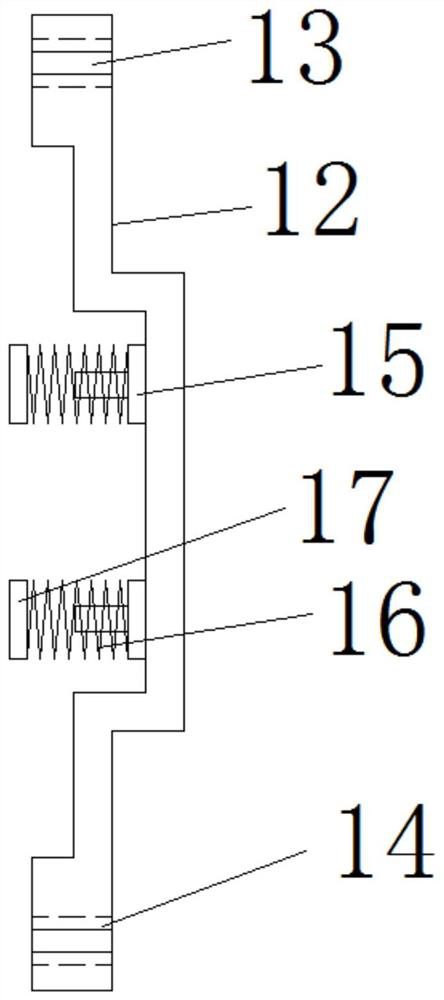

[0025] Embodiment one, such as Figure 1-5 As shown, according to the embodiment of the present invention, a double-ear wedge-shaped clamp for die-forging load-bearing cables includes a double-ear wedge-shaped clamp 1, and two double-ear wedge-shaped clamps 1 are arranged symmetrically. The sides of the clamp 1 in the circumferential direction are clamped and provided with elastic connectors 25, and a wedge cavity 2 is provided in the double-ear wedge-shaped wire clamp 1, and a wedge block 3 is provided in the wedge cavity 2. The double-ear wedge-shaped The top and the bottom of the clamp 1 are provided with two threaded holes 4, the threaded holes 4 are provided with bolts 10, the bolts 10 are provided with nuts 11, the bolts 10 and the nuts 11 connect the two The double-eared wedge-shaped wire clamp 1 and the elastic connector 25 in the middle are fixed together. One side of the double-eared wedge-shaped wire clamp 1 is provided with a connecting ear 5, and the middle part o...

Embodiment 2

[0026] Embodiment 2, the connecting ears 5 on the two double-eared wedge-shaped clamps 1 form double ears, and the connecting ears 5 and the double-eared wedge-shaped clamp 1 are integrally structured. It is not difficult to see from the above design that the design of the ears is relatively conventional, so no detailed description will be given.

Embodiment 3

[0027] Embodiment 3, the elastic connecting piece 25 is made of elastic metal material, the elastic connecting piece 25 is matched with the side of the double ear wedge clamp 1, the first chute 8 is connected with the second chute The specification of 13 is identical, and the specification of described draw-in slot one 9 is identical with described draw-in slot two 14. It is not difficult to see from the above design that the design of the elastic connector is relatively conventional, so no detailed description will be given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com