Wide and flat or semicontinuous wide and flat magnesium alloy ingot blank molding method

A sheet forming, semi-continuous technology, applied in the high-strength magnesium alloy forging forming process, can produce large-scale fields, can solve the problems of low room temperature plasticity, poor forming ability, small size of hot-rolled sheets, etc., achieve low energy consumption and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

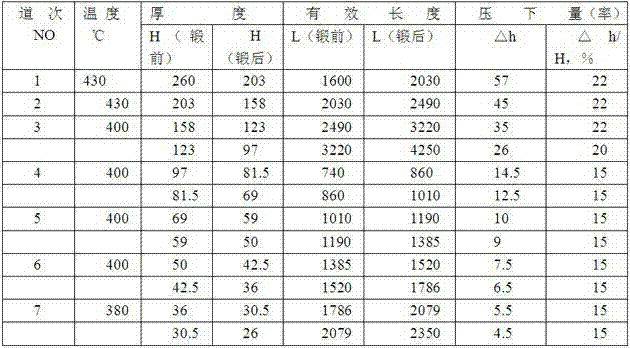

[0013] The following is an example to illustrate the production of magnesium alloy plates with product specifications of 28mm×1800mm×2100mm combined with the brand AZ31B.

[0014] 1. Ingot preparation: remove the oxide skin on the surface of wide flat magnesium alloy ingots with length, width and height of 260mm, 740mm and 1800mm, and then blunt the corners of the ingot.

[0015] 2. Homogenization treatment: place the billet at a temperature of 390°C for 20 hours.

[0016] 3. Billet heating: heat the billet to a surface temperature of 430°C, and hold for 4 hours.

[0017] 4. Forging:

[0018] A forging anvil with a continuous length and limited width with a groove is used. The groove is provided with a draft angle of 5-15°, and the size and shape of the hammerhead match the forging anvil.

[0019] Put the workpiece in the forging anvil, and under the action of the hammer head, forging is carried out in a step-by-step, multi-pass forging method. The forging ratio is not less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com