A cooling method for continuous casting slab

A cooling method and continuous casting slab technology, applied in the field of iron and steel metallurgical continuous casting, can solve problems such as huge investment, uneven structure, damage to steel properties, etc., to reduce segregation of alloy elements and harmful elements, dense as-cast structure, and improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

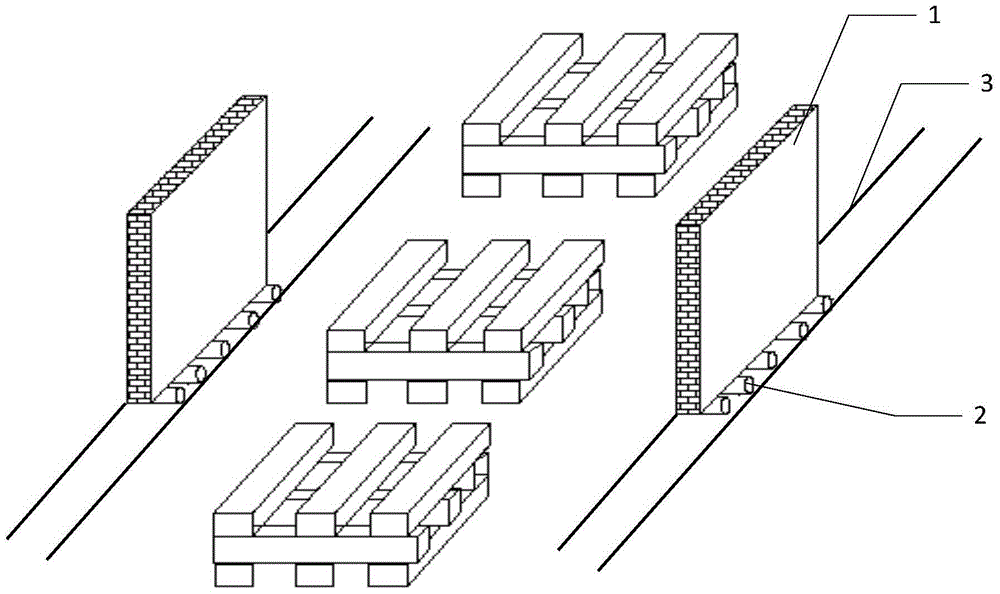

Image

Examples

Embodiment 1

[0045] When casting steel types with C%0.08, Si%0.26, Mn%1.45, P%0.018, S%0.008, V%0.040, Ti%0.020, divide the 100t slab of the same heat into two parts, one of which is Conventional mode cooling and stacking cooling, another batch is cooled in the preheated slow cooling controlled stack with the cooling device and cooling method described in the present invention, and the continuous casting slab low structure, segregation degree and The gas content of continuous casting slab N, H and O content were analyzed and compared.

[0046]Using the cooling device and cooling method of the present invention: the low-magnification microstructure results show that the central segregation of the steel is 0.5, the fine equiaxed grain area accounts for 12.1% of the total area of the continuous casting slab, and the columnar grain area accounts for 43.9% of the total area of the continuous casting slab. The equiaxed grain area accounts for 43.6% of the total area of the continuous casti...

Embodiment 2

[0050] When casting steel grades with C%0.09, Si%0.24, Mn%1.42, P%0.012, S%0.006, Nb%0.029, V%0.022, Ti%0.016, divide the 100t slab of the same heat into two parts, Wherein one batch is cooled by stacking in a conventional manner, and the other batch is cooled in the preheated slow cooling controlled stack by the method of the present invention, and the continuous casting slab low structure, segregation degree and The gas content of continuous casting slab N, H and O content were analyzed and compared.

[0051] Using the cooling device and cooling method of the present invention: the low-magnification microstructure results show that the steel center segregation is 0.5, the fine equiaxed grain area accounts for 12.3% of the total area of the continuous casting slab, and the columnar grain area accounts for 42.6% of the total area of the continuous casting slab. The equiaxed grain area accounts for 44.8% of the total area of the continuous casting slab, and the segregatio...

Embodiment 3

[0055] When casting steel grades with C% 0.08, Si% 0.26, Mn% 1.45, P% 0.018, S% 0.008, Nb% 0.030, Cr% 0.035, Ni% 0.035, Cu% 0.065, Ti% 0.013, the same furnace The 100t slab is divided into two parts, wherein one batch is cooled by stacking in a conventional manner, and the other batch is cooled in the preheated slow cooling controlled stack by the method of the present invention, respectively for the continuous casting after slow cooling The billet low-magnification structure, segregation degree and continuous casting billet gas content N, H, O content were analyzed and compared.

[0056] Using the cooling device and cooling method of the present invention: the results of the low-magnification structure show that the central segregation of steel is 0.5, the fine equiaxed grain area accounts for 11.8% of the total area of the continuous casting slab, and the columnar grain area accounts for 44.0% of the total area of the continuous casting slab. The equiaxed grain area acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com