Full-automatic laser welding device for battery production

A welding equipment, fully automatic technology, applied in the direction of welding equipment, welding equipment, laser welding equipment, etc., can solve the problems of low solder joint position accuracy, difficult positioning, small PCB board size, etc., to improve welding and detection efficiency, Improve the product yield rate and realize the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

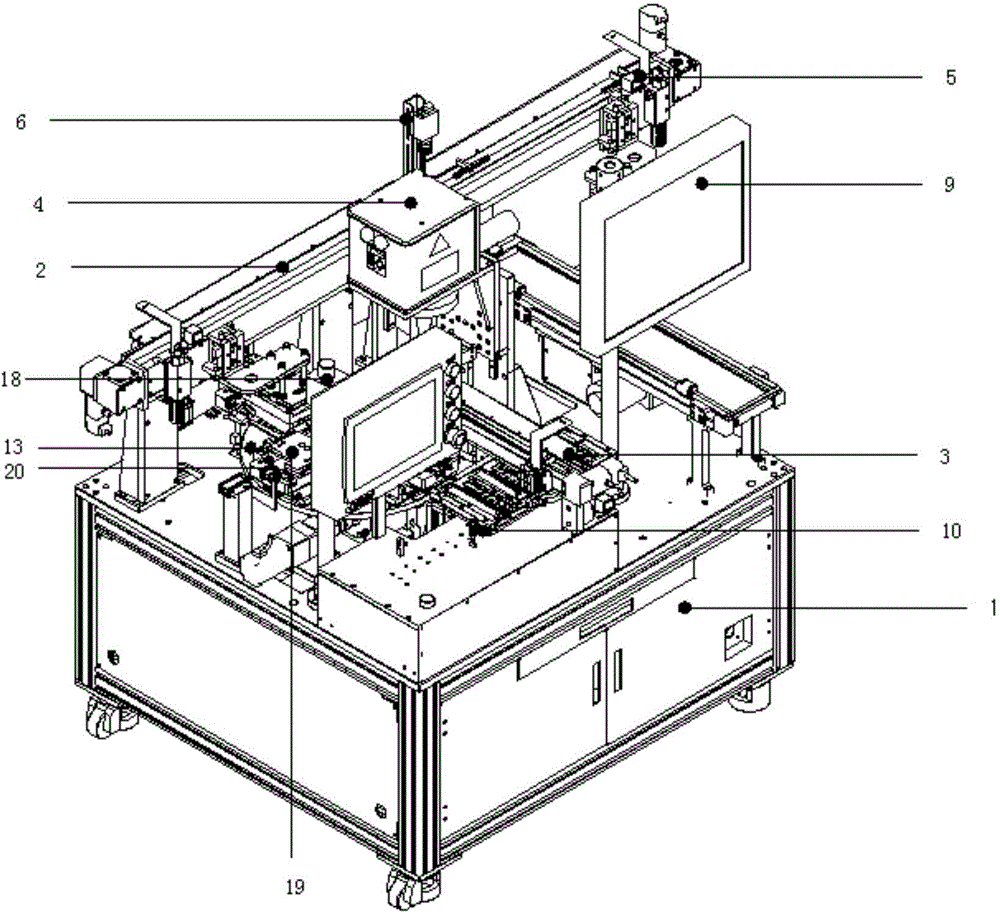

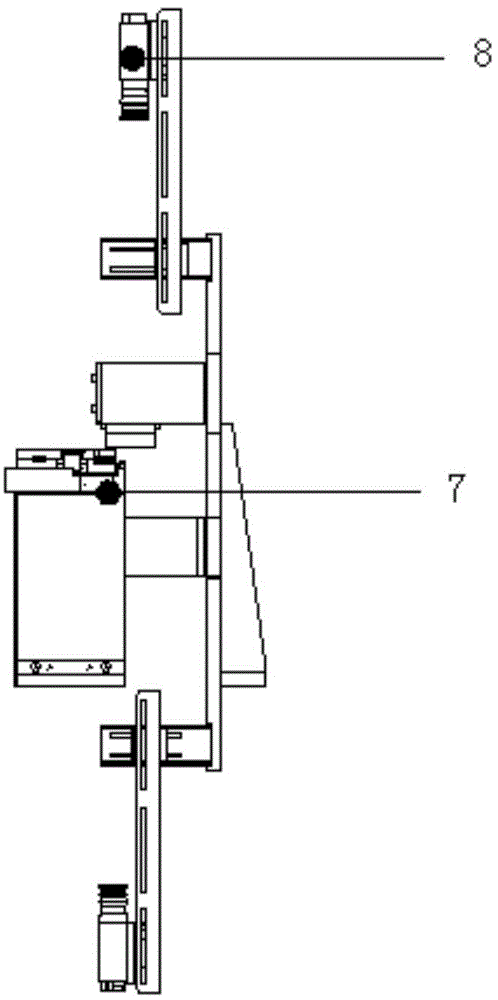

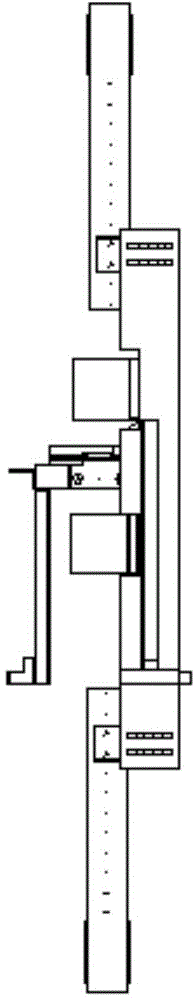

[0021] Embodiment: A fully automatic laser welding device 4 for battery production, including a frame 1, a product feeding device 2, a PCB board feeding device 3, a clamping fixture, a laser welding device 4, a feeding device 5 and a controller , the clamping jig is fixed on the frame 1, the clamping jig is provided with first and second positioning devices and a gland, wherein the first positioning device can fix and position the clip 19 with the battery installed, and the second positioning The device can fix and position the PCB board 20, the gland can keep the battery on the first and second positioning devices closely attached to the soldering part of the PCB board 20, and the product feeding device 2 can place the clip 19 with the battery on the clamping device. On the first positioning device of the tool, the PCB board feeding device 3 can place the PCB board 20 on the second positioning device, and the laser beam of the laser welding equipment 4 can just be projected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com