Calibration method of laser galvanometer processing system under guidance of binocular stereoscopic vision

A technology of binocular stereo vision and laser galvanometer, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of low precision of laser processing, achieve accurate visual feedback laser processing, easy to operate and stable sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

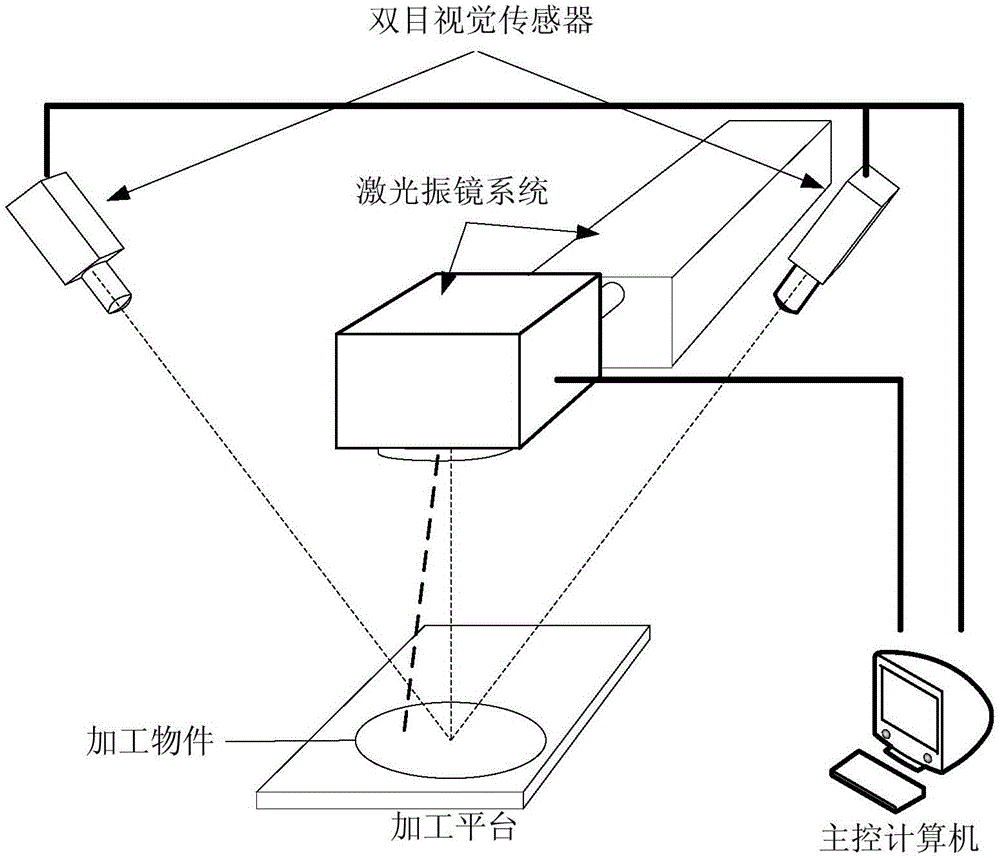

[0024] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0025] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

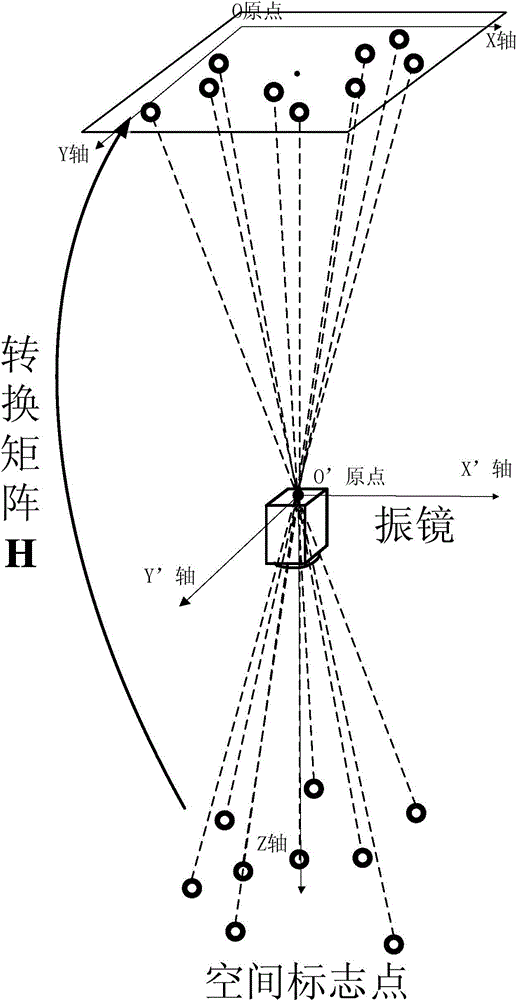

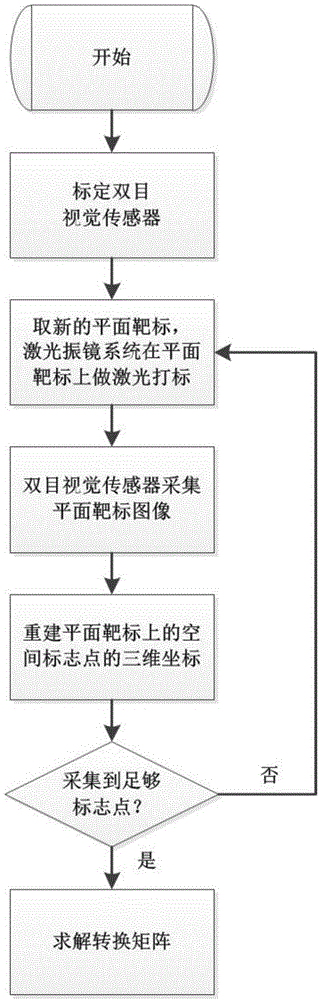

[0026] A calibration method for a laser galvanometer processing system guided by binocular stereo vision, which obtains dense marker points through laser marking within the depth of field of the laser galvanometer processing system, and then uses the three-dimensional coordinates of these marker points and their position in the laser The corresponding relationship of the two-dimensional coordinates in the laser galvanometer processing graphics coordinate system of the galvanometer processing system can accurately solve the mapping relationship between the binocular vision sensor and the laser galvanometer processing system, and improve the processing accuracy of visual feedback.

[0027] Since the galvanometer system ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com