Lathe spindle indexing locking mechanism

A technology of a lathe spindle and a locking mechanism, which is applied in automatic/semi-automatic lathes, turning equipment, metal processing machinery parts, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

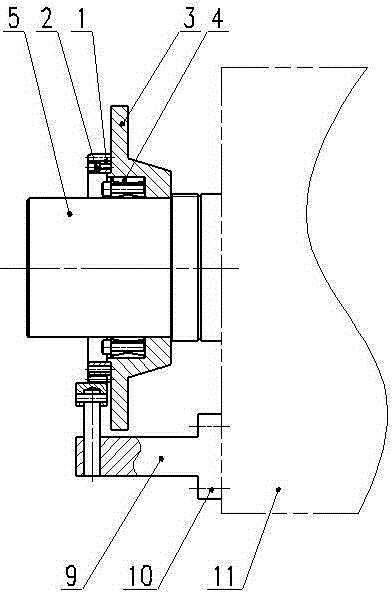

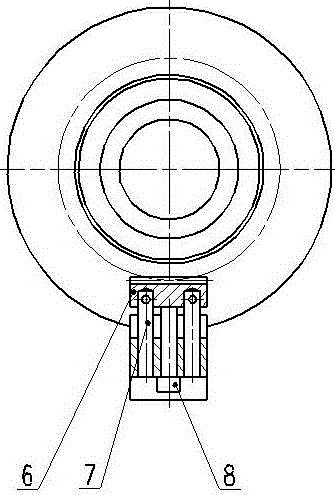

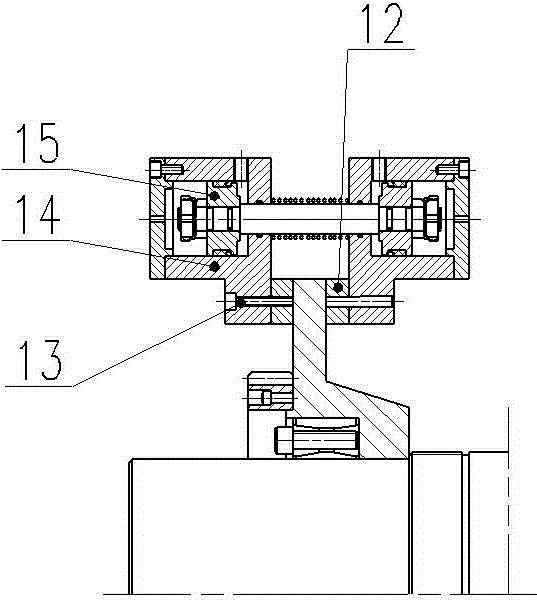

[0021] Such as Figure 1 to Figure 3 As shown, the indexing and locking mechanism of the lathe spindle includes an indexing plate fixed relative to the lathe spindle 5, an indexing plate positioning mechanism for realizing position locking and unlocking of the indexing plate, a brake disc 3 fixed relative to the lathe spindle, and a brake disc 3 respectively located on the brake disc. Brake pads 12 on both sides and a brake pad drive mechanism that makes the two brake pads approach or move away from each other. Both the axis of the indexing disc and the axis of the brake disc coincide with the axis of the main shaft of the lathe.

[0022] The indexing disk is a ring gear 1, and the indexing disk positioning mechanism includes a rack 6 cooperating with the ring gear and a rack moving mechanism for realizing the engagement or disengagement of the rack and the ring gear. The rack moving mechanism includes a base 9 fixed on the bedside box 11, an adjusting screw 8 pierced on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com