Anti-deformation fixing clamp for automobile door handle

A technology for fixing fixtures and preventing deformation. It is used in manufacturing tools, workpiece clamping devices, etc., which can solve the problems of scrapped workpieces, easy upturning at both ends, and improper installation, and achieve the effect of preventing parts from upturning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

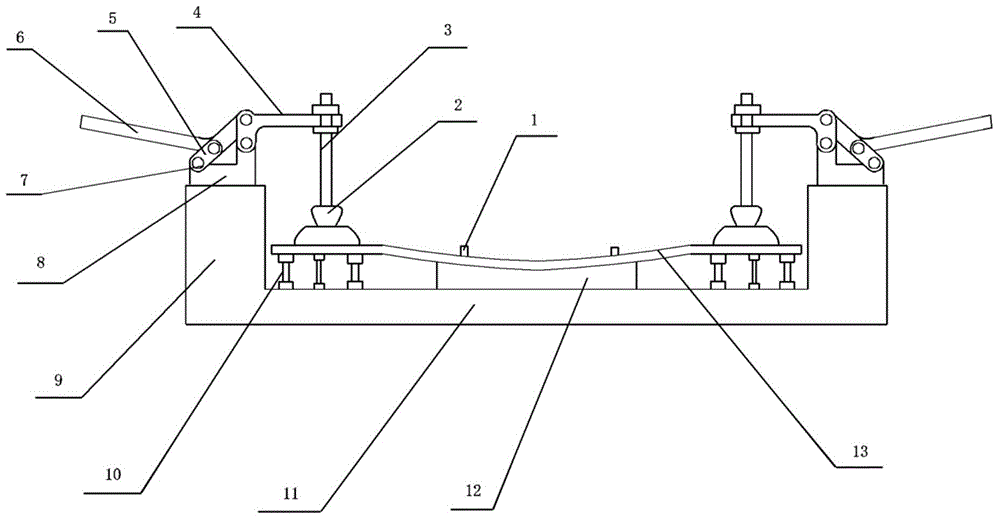

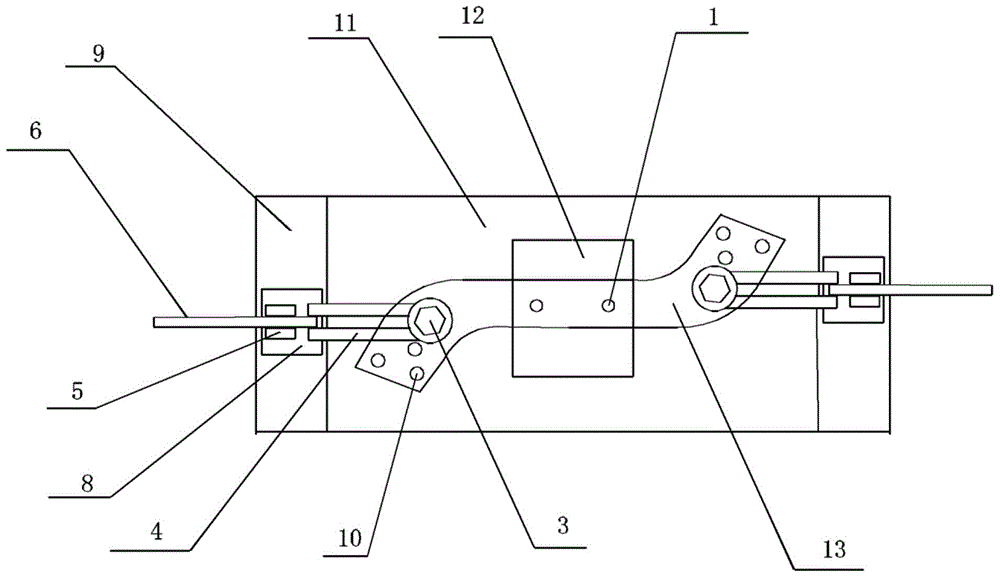

[0011] The anti-deformation fixing fixture of the automobile door handle includes a splint groove bottom plate 11, two side walls 9 and a pressing device. The middle position of the splint groove bottom plate 11 has an inherent arc-shaped tray 12, and two positioning pins are arranged on the arc-shaped tray 12. Column 1 has three support bolts 10 on the bottom plate 11 of the plywood groove near the two side walls; the pressing device is fixed on the side wall 9, and the pressing device includes a bracket 8, a pressure hammer 2, a handle 6, and an L-shaped The connecting rod 4 and the in-line connecting rod 5, the pressure hammer 2 are fixed on the L-shaped connecting rod 4 through the bolt 3.

[0012] Described handle 6 and L-shaped connecting rod 4, handle 6 and inline connecting rod 5, L-shaped connecting rod 4 and support 8, inline connecting rod 5 and support 8 are all connected by horizontal rotating shaft 7.

[0013] The door handle part 13 is placed on the arc-shaped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com