Coupling filter material replacement biological filter

A filter and biological technology, applied in the direction of biological water/sewage treatment, special treatment targets, water/sludge/sewage treatment, etc., can solve problems affecting the installation of filter elements, and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

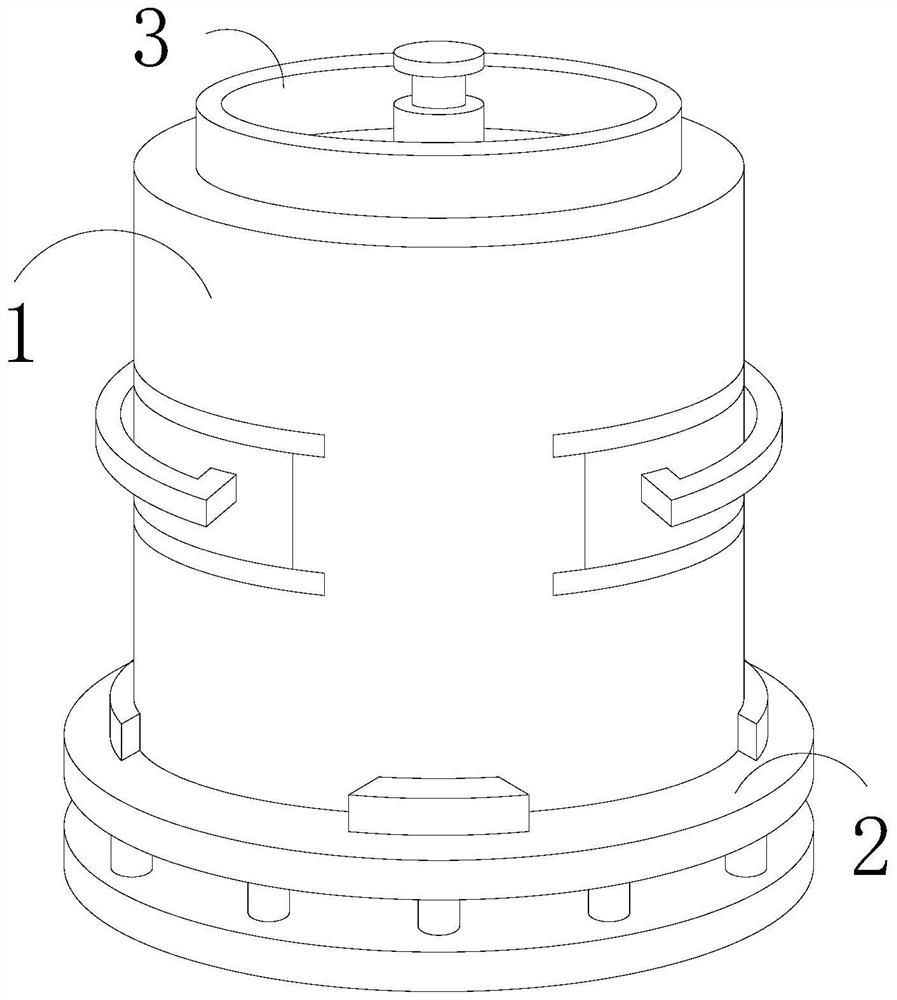

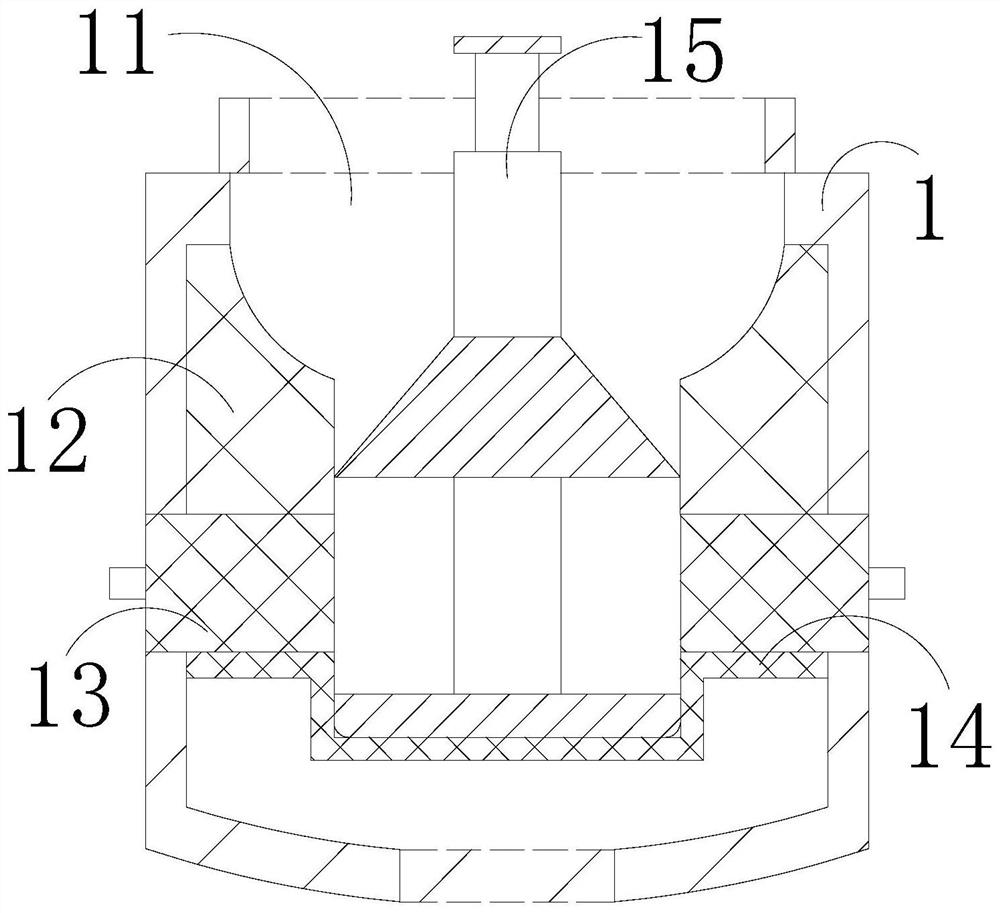

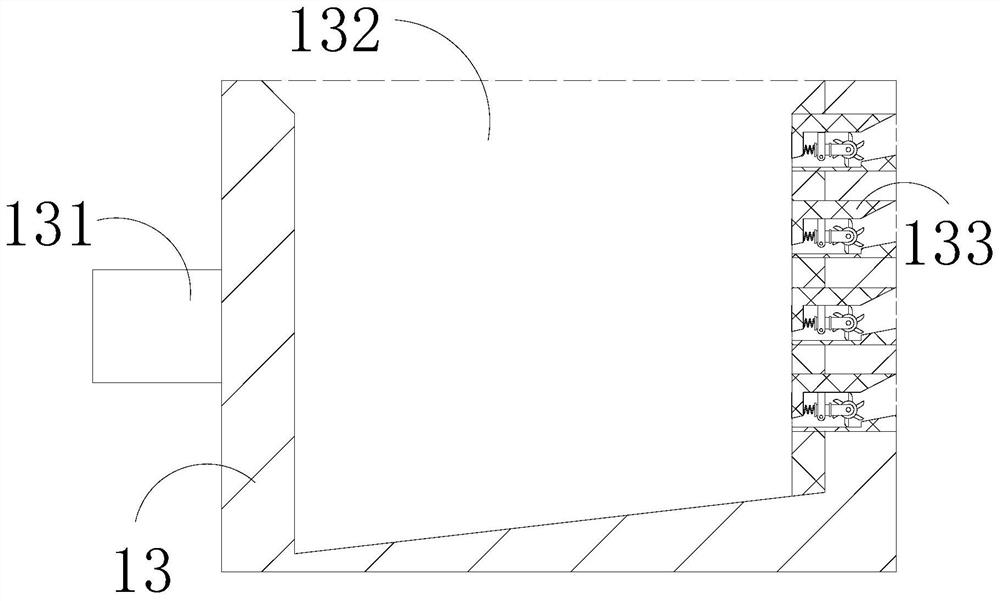

[0029] The invention provides a coupling filter material replacement biological filter, the structure of which includes a filter cartridge 1, a base 2, and an interface 3. The bottom of the filter cartridge 1 is embedded on the upper surface of the base 2, and the bottom of the interface 3 is connected to the filter by welding. The top of the cartridge 1, the filter cartridge 1 includes a filter chamber 11, a filter screen 12, an isolation block 13, a filter plate 14, and a filter element 15, the filter chamber 11 is embedded in the filter cartridge 1, and the filter screen 12 is embedded in the On the inner wall of the filter chamber 11, the spacer block 13 is connected to the inside of the filter cartridge 1 through movable engagement and is located directly below the filter screen 12, the filter plate 14 is connected to the inner wall of the filter chamber 11 by welding, and the bottom of the filter element 15 is close to the On the upper surface of the center of the filter ...

Embodiment 2

[0035]The invention provides a coupling filter material replacement biological filter, the structure of which includes a filter cartridge 1, a base 2, and an interface 3. The bottom of the filter cartridge 1 is embedded on the upper surface of the base 2, and the bottom of the interface 3 is connected to the filter by welding. The top of the cartridge 1, the filter cartridge 1 includes a filter chamber 11, a filter screen 12, an isolation block 13, a filter plate 14, and a filter element 15, the filter chamber 11 is embedded in the filter cartridge 1, and the filter screen 12 is embedded in the On the inner wall of the filter chamber 11, the spacer block 13 is connected to the inside of the filter cartridge 1 through movable engagement and is located directly below the filter screen 12, the filter plate 14 is connected to the inner wall of the filter chamber 11 by welding, and the bottom of the filter element 15 is close to the On the upper surface of the center of the filter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com