Intelligent high-speed cargo conveying system of pipeline train

A train control system and train technology, applied in the field of cargo conveying systems in the logistics industry, can solve the problems of large resource input consumption, high consumption cost, and the ability to quickly deliver difficult goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention are described in conjunction with the accompanying drawings.

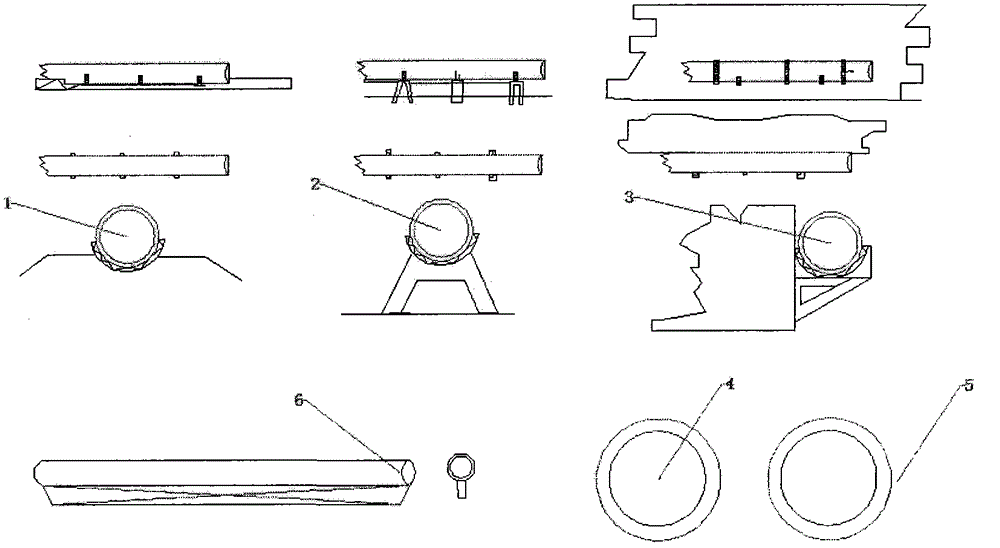

[0043] figure 1 Shown: 1-road laying, 2-overhead laying, 3-suspension laying, 4-pipe diameter 1.2M-1.7M, 5-pipe thickness 0.06M-0.18M, 6-long pipe laying, using concrete materials or synthetic Material pours fixed composition.

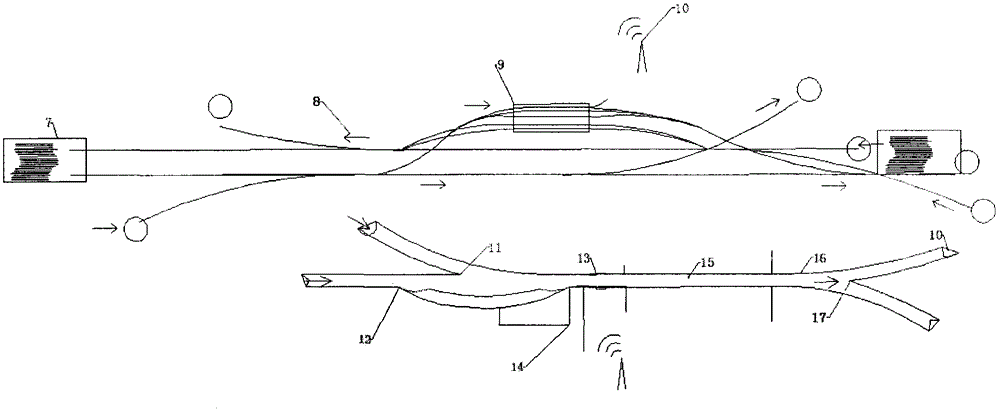

[0044] figure 2 Shown: 7-train station, 8-pipeline train one-way lane, 9-train station and maintenance center, 10-pipeline train exit, 11-pipeline confluence point, 12-pipeline maintenance port, 13-train deflation point, 14 -Train maintenance service center, 15-Pipeline sealing section, 16-Train transportation pipeline, 17-Pipeline diversion section. According to the steps in the pipeline laying process figure 1 Continue to lay pipelines along the destination, and set up at least one distribution station and maintenance center every 50KM-100KM.

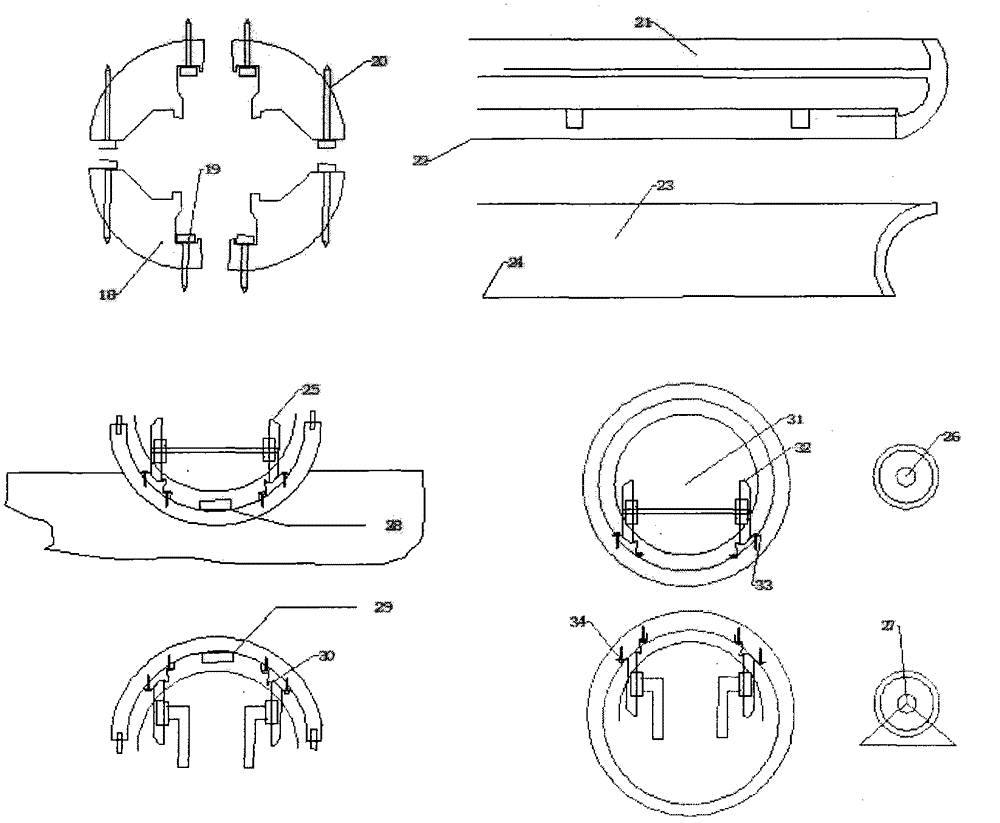

[0045] image 3 Shown: 18-power rail under the track, 19-rail fixing device, 20-sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com