Automatic small cargo shelving car

A technology for automatic shelving and goods, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of poor flexibility, large area and high cost, and achieve the effect of low cost, strong adaptability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

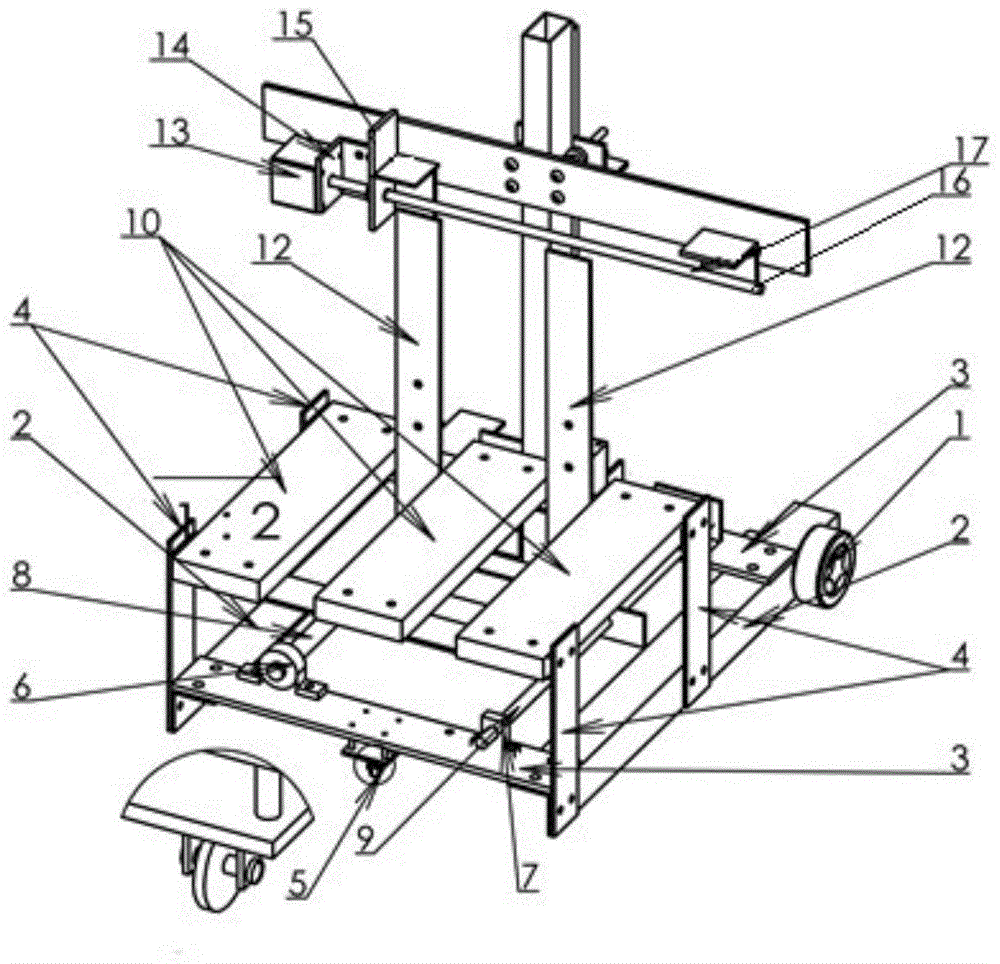

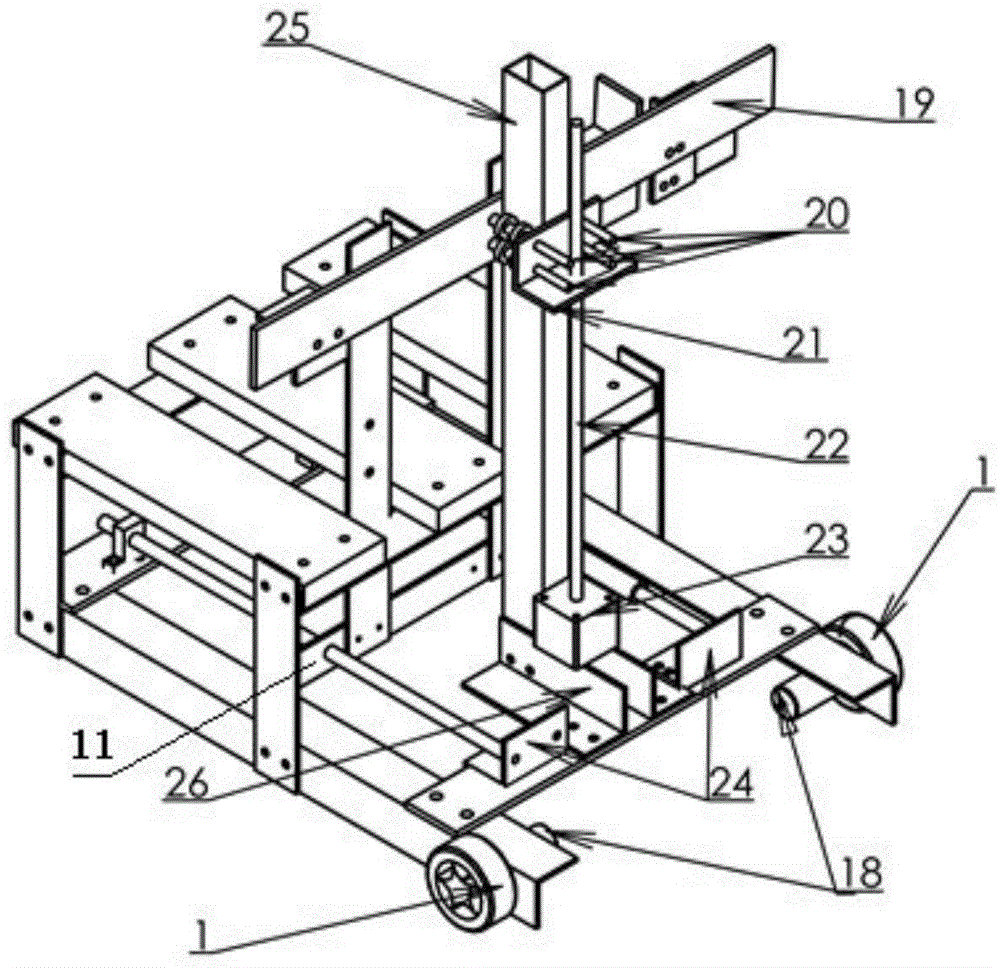

[0023] Such as Figure 1-2 As shown in the figure, the automatic loading vehicle for small goods includes two parts: the main mechanism of the vehicle body and the power drive adjustment mechanism.

[0024] Described car body body mechanism comprises rear wheel 1, left and right chassis 2, front and rear chassis 3, vertical support 4, universal wheel 5, cargo temporary storage rack 10, cargo storage rack 17, DC motor b18, angle aluminum 24.

[0025] The power-driven adjustment mechanism includes an x-axis drive mechanism, a y-axis drive mechanism, and a z-axis drive mechanism; the x-axis and y-axis are horizontal directions perpendicular to each other, and the z-axis is a vertical direction.

[0026] The x-axis drive mechanism includes a stepping motor a13, a fixed support 14, an x-axis push plate 15, and a lead screw a16.

[0027] The y-axis drive mechanism includes a DC motor a6, a smooth shaft support 7, a lead screw b8, a smooth shaft 9, a y-axis horizontal push plate 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com