Circulating type stereoscopic warehouse

A three-dimensional warehouse, circulating technology, applied in the warehouse field, can solve the problems of vibration, high noise, long material picking time, large motor power loss, etc., to reduce vibration and noise, improve warehouse space utilization, and reduce electrical power loss. and the effect of using energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

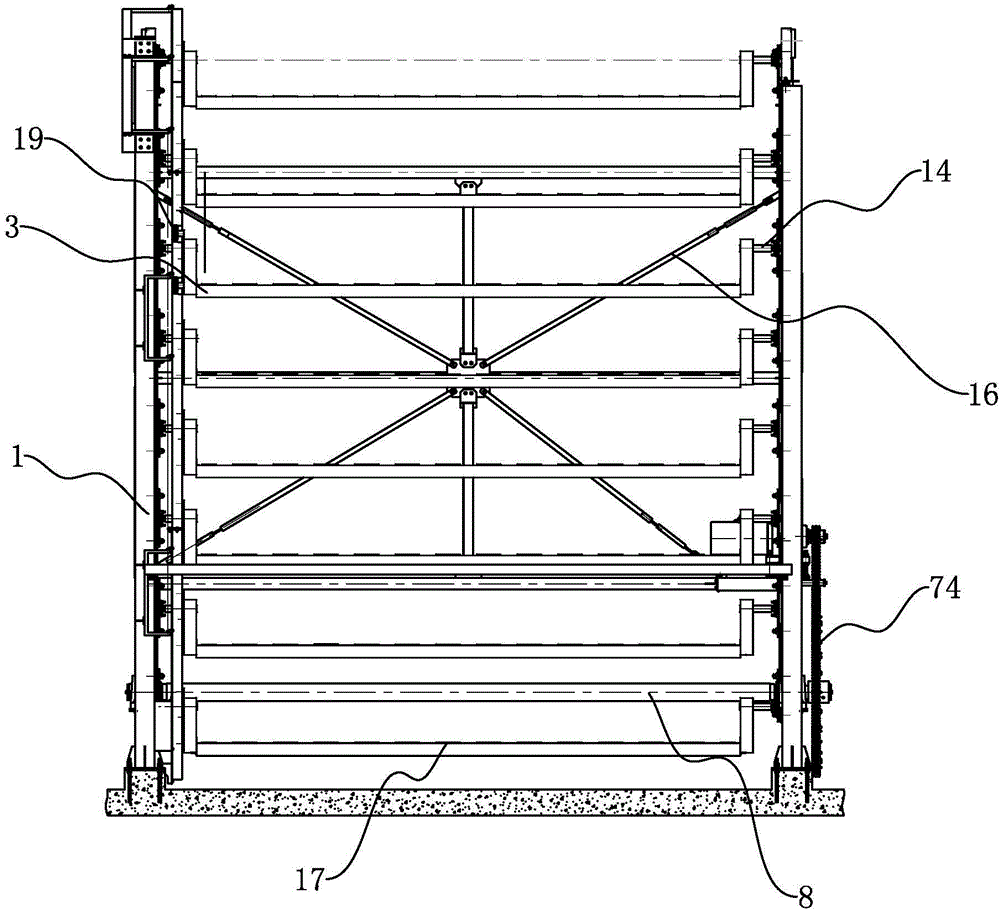

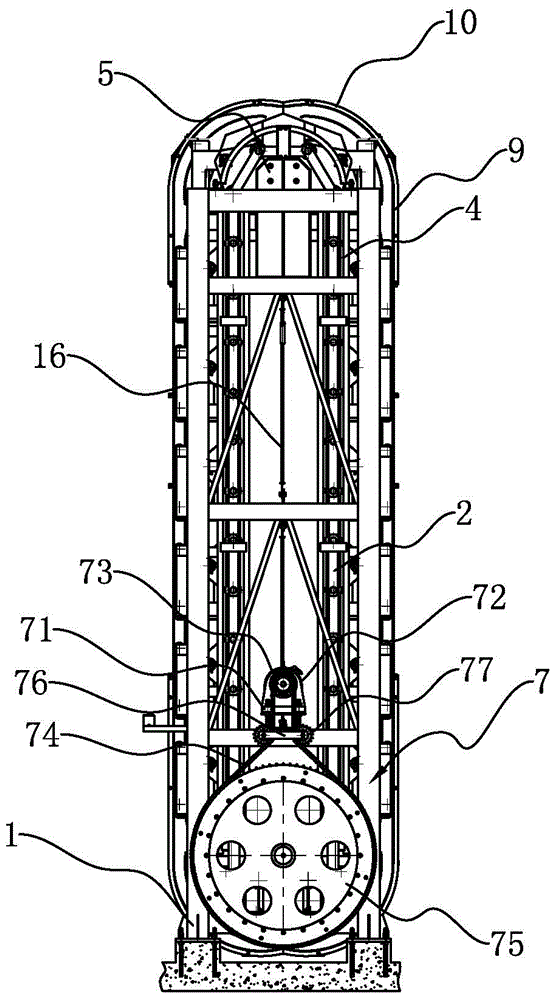

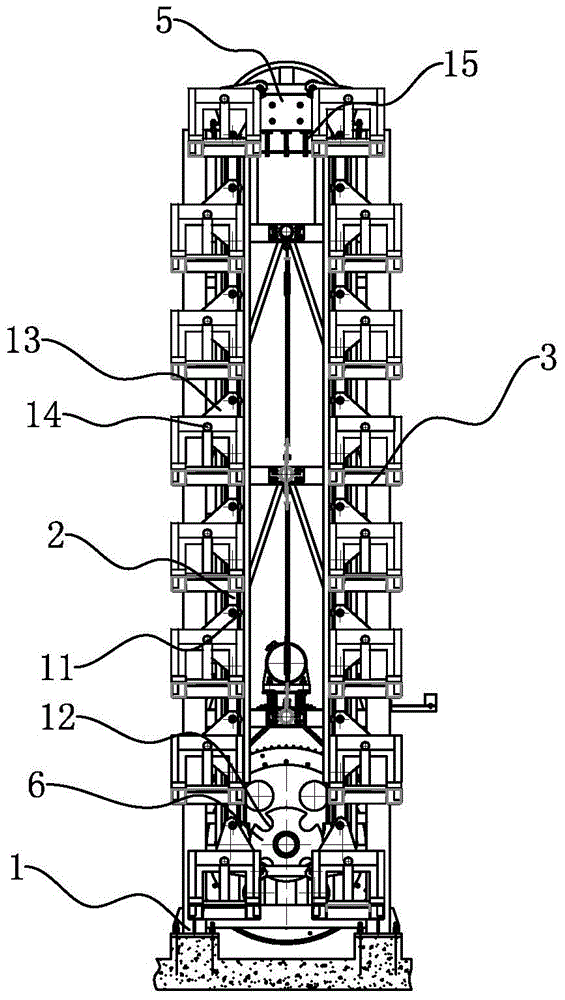

[0020] refer to Figure 1 to Figure 3 , a circular three-dimensional warehouse of the present invention, comprising a main frame 1, the left and right sides of the main frame 1 are respectively provided with vertical lifting chains 2, and the front and rear sides of the main frame 1 are respectively provided with a plurality of material storage units 3 , the material storage unit 3 is vertically arranged, and its two ends are respectively connected with the vertical lifting chains on the left and right sides, and the left and right sides of the main frame 1 are respectively provided with lifting chain guide rails 4, and the vertical lifting chain 2 is located at The lifting chain guide rail 4 can circulate along the lifting chain guide rail. The upper part of the main frame 1 is provided with a support member 5 for supporting the vertical lifting chain, and the lower part of the main frame 1 is installed with a toggle chain engaged with the vertical lifting chain. Wheel 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com