Non-return device of coal loading conveyor belt

A non-return device and conveyor belt technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as not having coal blocking function, conveyor belt deviation, breakage, etc., to save labor intensity and time , prolong service life, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

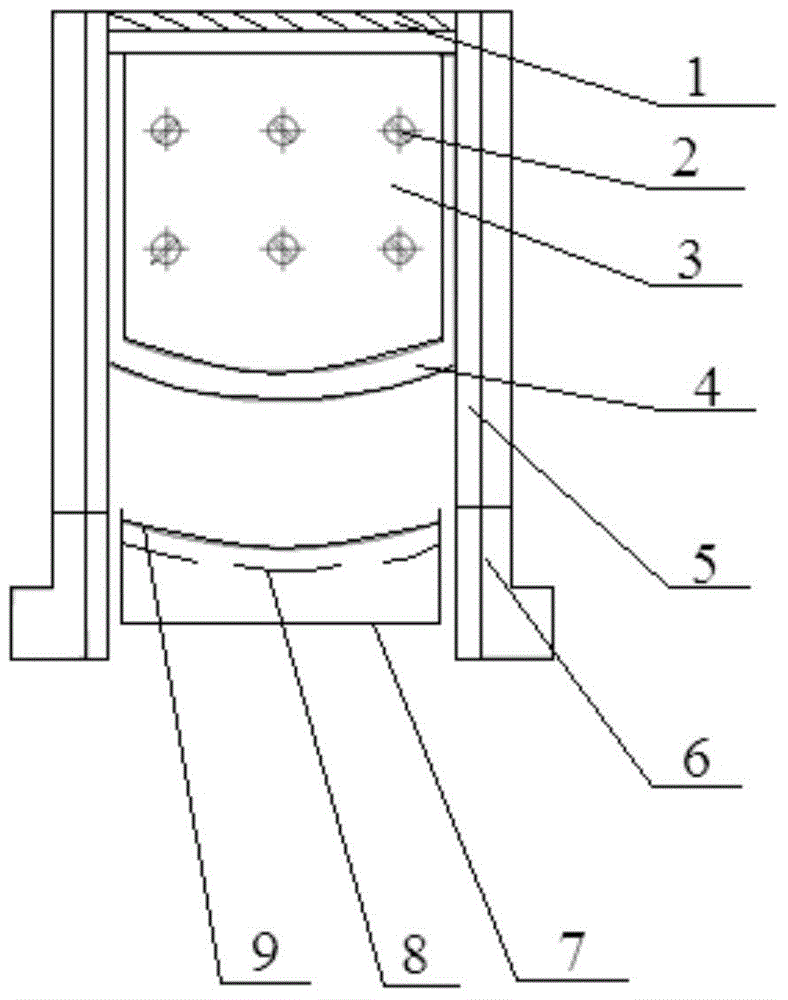

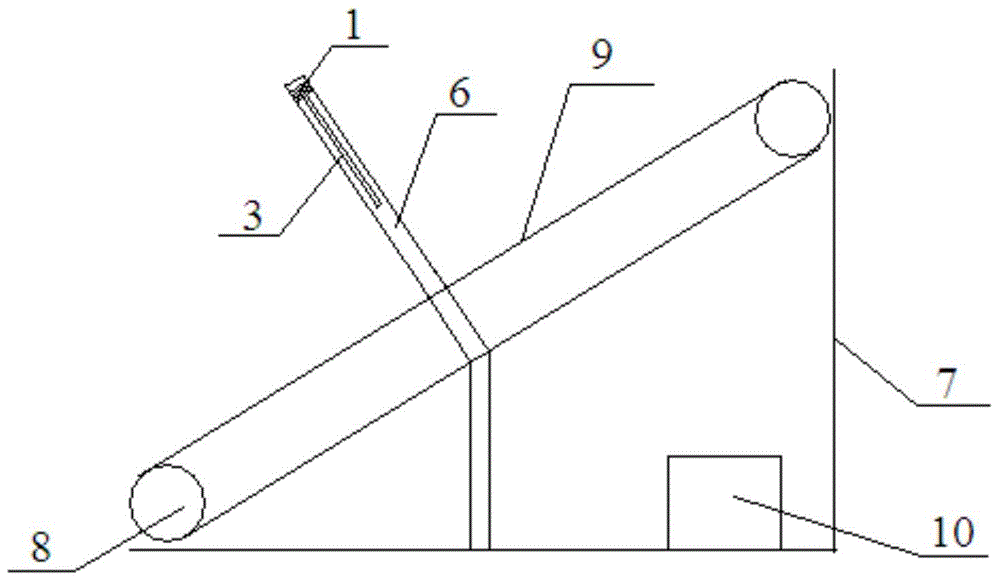

[0017] A kind of coal conveyor belt non-return device, such as figure 1 , figure 2 As shown, it is arranged above the conveyor belt 9, and a roller 8 connected to the motor is provided below the conveyor belt 9, and the roller 8 drives the conveyor belt 9 to rotate up and down, and a conveyor belt bracket 7 is also provided below the conveyor belt 9. The non-return device includes Baffle support 6, steel baffle 3, electromagnet 1 and controller 10, baffle support 6 is arranged on the both sides of conveyer belt 9, and is positioned at the middle and lower part of conveyer belt 9, and baffle support 6 and conveyer belt 9 surface Vertically, the electromagnet 1 is located at the top of the baffle bracket 6, and when the electromagnet 1 is energized, it will hold the steel baffle 3 so that the steel baffle 3 is located at the top of the baffle bracket 6, and when the electromagnet 1 is powered off, the steel baffle 3 will fall Intercept the lump of coal on the conveyor belt 9 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com