Full-automatic web combined die cutting machine

A roll paper, fully automatic technology, applied in the direction of winding strips, sending objects, stacking receiving devices, etc., can solve the problems of wasting manpower, wasting paper, and low work efficiency, so as to reduce corner waste and improve utilization rate Improvement, simple structure and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

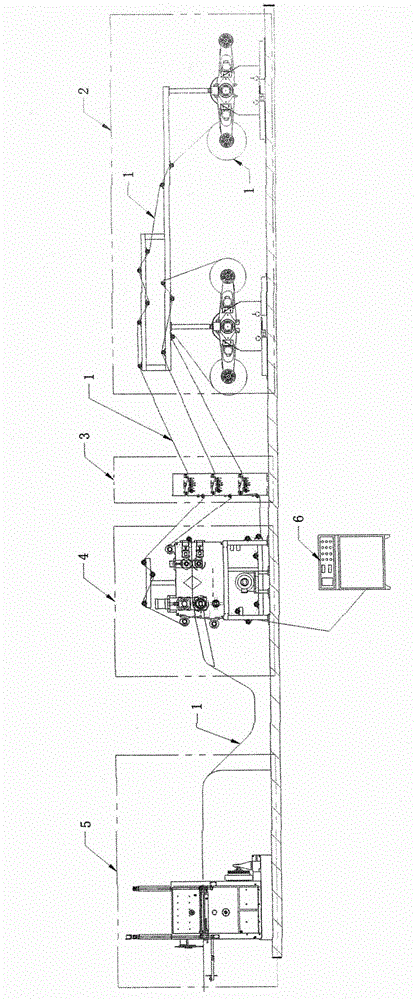

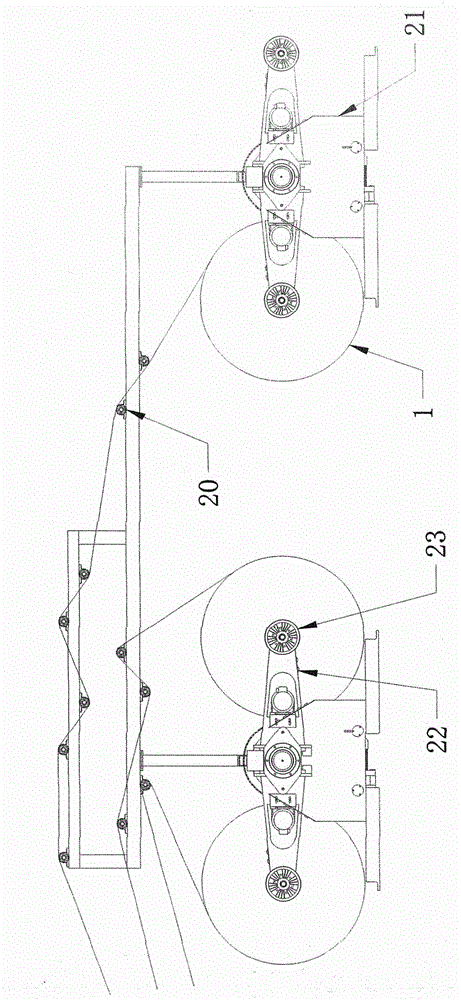

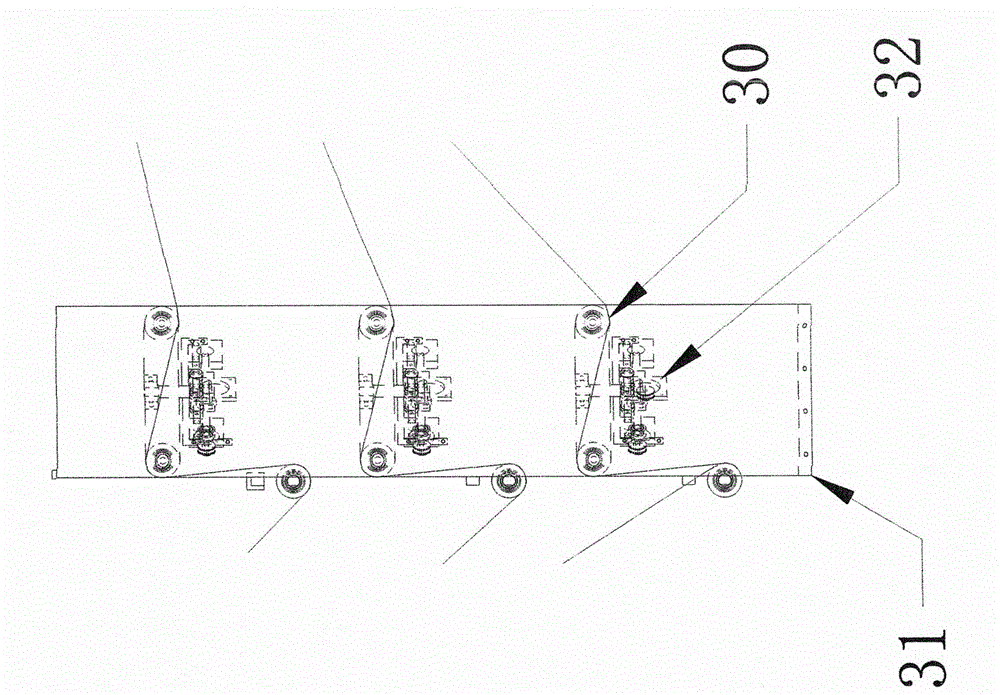

[0014] refer to figure 1 It can be seen that the automatic web compound die-cutting machine of the present invention applied to printing and packaging machinery includes paper feeding mechanism 2 (see figure 2 ), the side of the paper feeding mechanism 2 is sequentially equipped with a deviation correction mechanism 3 (see image 3 ), composite mechanism 4 (see Figure 4 ), die-cutting mechanism 5 (see Figure 5 ), the paper feeding mechanism 2, the correction mechanism 3, the composite mechanism 4, and the die-cutting mechanism 5 are all electrically connected to the microcomputer control mechanism 6, and are uniformly regulated by it. The paper unwound from the roll paper 1 installed on the paper feeding mechanism 2 runs through the paper feeding mechanism, the deviation correction mechanism (deviation correction processing), the composite mechanism (composite processing), and the die-cutting mechanism (die-cut processing).

[0015] Wherein, the paper feeding mechanism 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap