A Modular Process Variable Type Direct Drinking Water System

A variable and direct drinking water technology, applied in the field of water treatment, can solve the problems of water activity reduction, neglect, loss of supplementary minerals, etc., to prevent conflicts or duplication, eliminate waste of resources, and maximize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

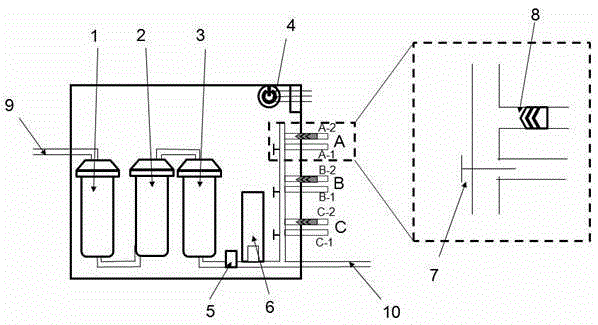

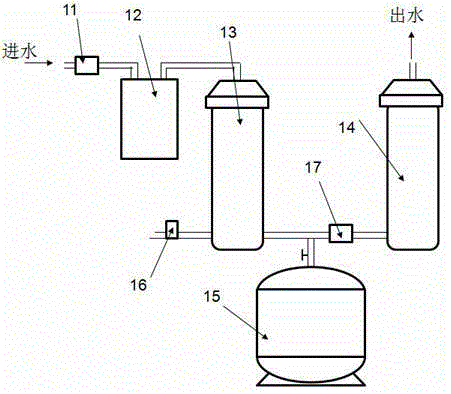

[0028] Such as figure 1 The modular process-variable direct drinking water system shown includes a basic purification module, which includes pp cotton filter 1, activated carbon adsorption filter 2, precision filter 3 and ultraviolet sterilizer 6, and the upper part of pp cotton filter 1 Connected with a water inlet 9, the lower part is connected to the bottom of the activated carbon adsorption filter 2, the upper part of the activated carbon adsorption filter 2 is connected to the top of the precision filter 3, the bottom of the precision filter 3 is connected to the bottom of the ultraviolet sterilizer 6; the ultraviolet sterilizer 6 The outlet is connected with a water outlet 10; the basic purification module is provided with a plurality of three-way ball valves 7 and one-way valves 8, which are used to connect external RO purification modules, mineralization modules, softening modules or refrigeration and heating modules. The basic purification module is provided with a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com