A kind of tailings powder wet mixing plastering mortar

A technology for plastering mortar and tailings, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of increasing carbon dioxide and dust emissions, energy consumption, and short operating time for mortar construction, etc. To achieve the effect of reducing carbon dioxide and dust emissions, reducing shrinkage, and prolonging construction operation time

Active Publication Date: 2016-09-07

CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These technical solutions solve the problem of tailings reuse to a certain extent, but the operation time of mortar construction is short, and the utilization rate of tailings generally does not exceed 20% of its own mass

Moreover, all these technical solutions involve dry-mixed mortar. During the preparation of mortar, fine aggregates such as natural sand and tailings must be dried, which will not only consume more energy, but also increase the emission of carbon dioxide and dust. quantity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~4

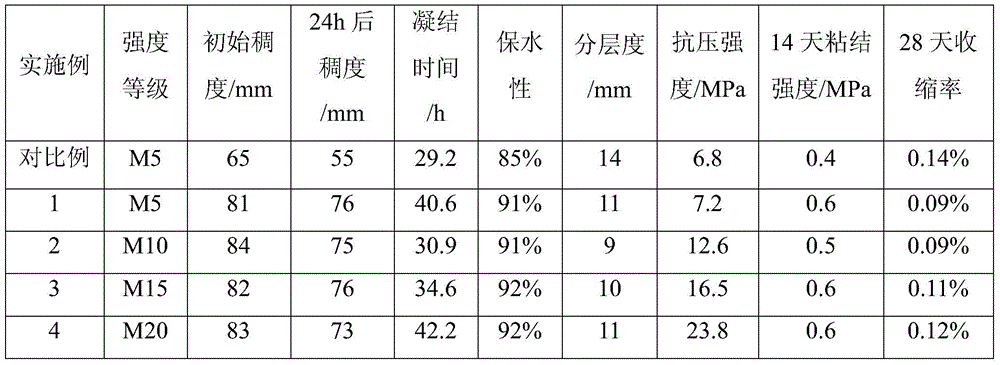

[0028] Table 1 The percentage by mass of each raw material in the mortar prepared in Examples 1 to 4 and Comparative Examples

[0029] Example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a tailing powder wet-mixed plastering mortar which is prepared from the following raw materials in mass percent via wet mixing: 5-10% of tailing powder, 60-75% of tailing manufactured sand,10-15% of cement, 0.5-1.5% of a plastic stabilizer, 0.1-0.5% of a retarder and the balance of water. The tailing powder wet-mixed plastering mortar can be used for effectively improving the resource recycling rate of the tailings so as to turn the tailings into wealth; tests show that the tailing powder can be used for improving the peaceability of mortar, improving the bonding strength of the mortar, reducing the shrinking percentage of the mortar, effectively preventing the mortar from cracking and hollowing, effectively reducing the consistency loss of the mortar and prolonging the construction operation time of the mortar. The mortar is low in production cost, stable in quality and long in construction operation time; by adopting a wet mixing technology, the fine aggregates such as the tailing manufactured sand and the like do not need to be dried, so that the energy-saving and environment-friendly green concept is met.

Description

technical field [0001] The invention belongs to the field of building materials, in particular to tailings powder wet-mixed plastering mortar. Background technique [0002] With the development of the national economy, the development scale of my country's metal mining industry is increasing day by day, and the amount of tailings discharged every year is as high as 1 billion tons. The long-term accumulation of a large number of tailings not only causes serious pollution to air, water and soil, but also occupies a large amount of agricultural land. In addition, if the management and design of the tailings pond are not good, collapse accidents will easily occur, causing casualties. For this reason, in April 2010, the Ministry of Industry and Information Technology of my country promulgated the "Special Plan for Comprehensive Utilization of Metal Tailings (2010-2015)", which clearly stated that the comprehensive utilization rate of tailings in the "Twelfth Five-Year Plan" should...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/00C04B18/30

CPCY02W30/91

Inventor 赵日煦刘通杨文高飞庞二波刘离缪凯

Owner CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com