A synergistic aerobic fermentation process of sludge after biological drying of traditional Chinese medicine residue

A technology of biological drying and aerobic fermentation, which is applied in the direction of sewage/sludge fertilizer, biological organic part treatment, fertilizer made from biological waste, etc., to achieve the effects of improving fermentation efficiency, stable product properties, and short fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

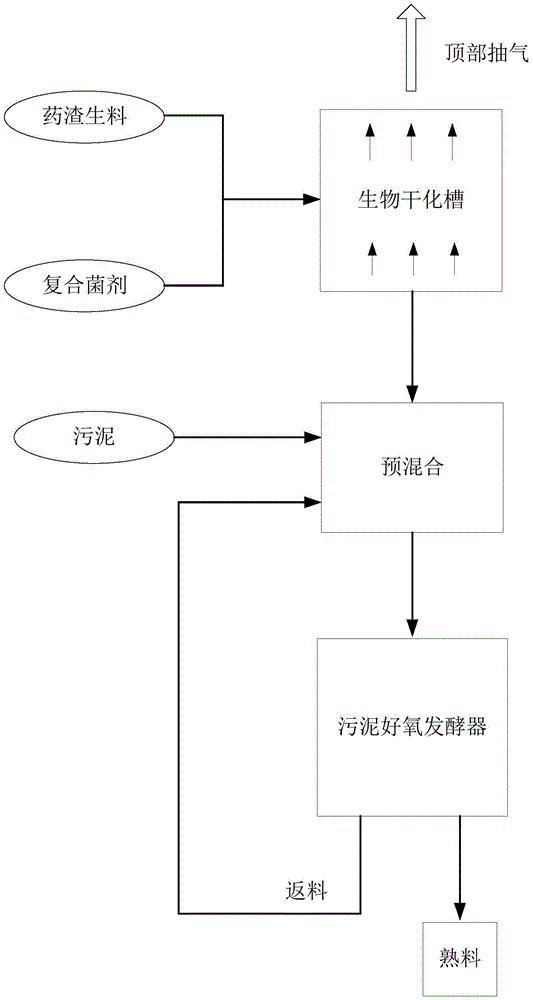

[0026] like figure 1 As shown, the present invention provides a collaborative sludge aerobic fermentation process after biological drying of traditional Chinese medicine residue, which is carried out in a sewage treatment plant:

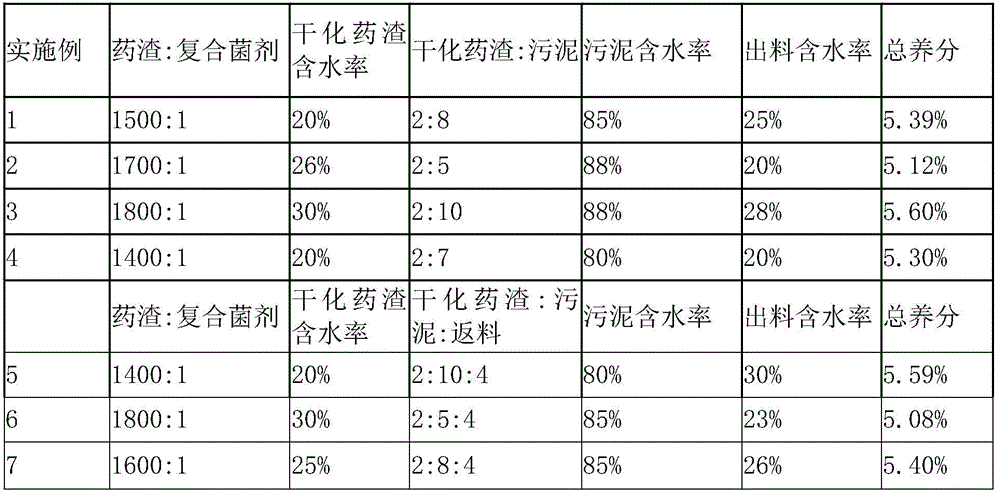

[0027] First, 15kg of traditional Chinese medicine slag and 10g of compound microbial agent after the initial dehydration of the traditional Chinese medicine factory are mixed evenly, wherein the compound microbial agent is 3:3:1:2 according to the weight and number ratio of alcoholic yeast, Aspergillus niger, Bacillus thuringiensis, and Trichoderma viride The ratio of the preparation, the initial moisture content of the dregs of the medicine is about 85%; then the mixed dregs and the compound bacterial agent are stacked in the biological drying tank, the bottom is forced to ventilate, and the top fan is drawn, and dried for 4 days. The moisture content after drying was measured to be 20%. Take the sludge with a water content of about 85% after prel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com