Polyethylene composition and preparation method thereof

A technology of polyethylene and composition is applied in the field of polyethylene composition for preparing breathable film and its preparation, and achieves the effects of stable performance, good compatibility and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

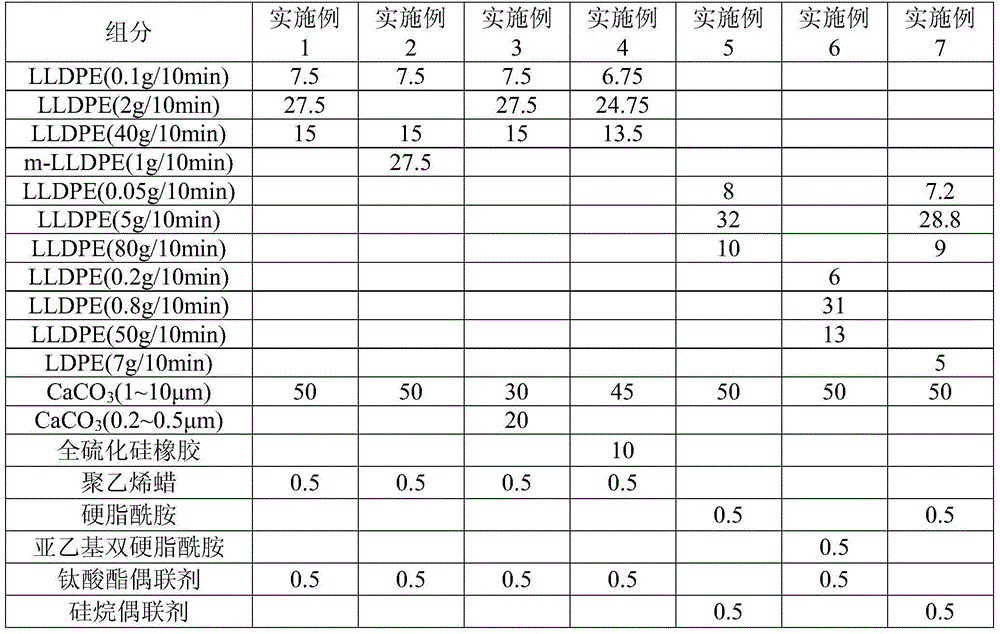

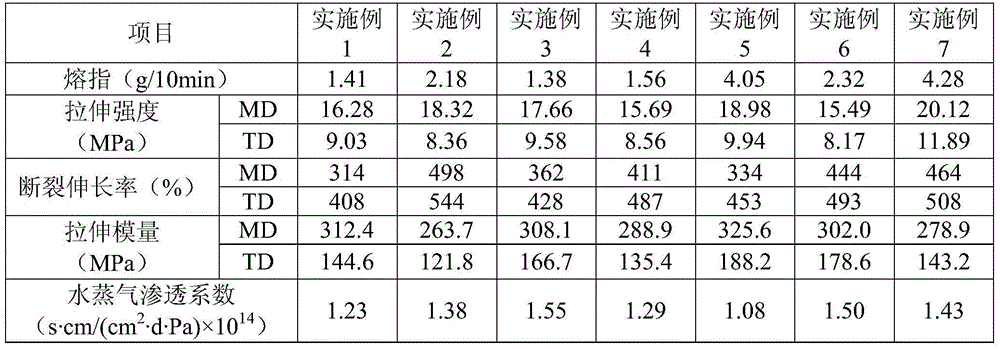

Embodiment 1

[0028] Add 50 parts of calcium carbonate with a particle size of 1-10 microns into the high-speed mixer, set the temperature at 110-120°C, stir at high speed for 10 minutes, add 0.5 parts of titanate coupling agent and continue stirring at high speed for 10 minutes; then , add 0.5 parts of dispersant polyethylene wax, stir at high speed for 10 minutes; finally, add 7.5 parts of linear low density polyethylene with a melting index of 0.1g / 10min, 27.5 parts of linear low density polyethylene with a melting index of 2g / 10min, melt Refers to 15 parts of 40g / 10min linear low-density polyethylene, mixed evenly at a low speed, added to a twin-screw extruder, melted and blended, extruded, and granulated to obtain a polyethylene composition. The polyethylene composition is cast and stretched to obtain a breathable film product, which can be widely used in the fields of disposable hygiene products, waterproof and moisture-permeable materials, and the like. The weight fraction of each co...

Embodiment 2

[0031]Add 50 parts of calcium carbonate with a particle size of 1-10 microns into the high-speed mixer, set the temperature at 110-120°C, stir at high speed for 10 minutes, add 0.5 parts of titanate coupling agent and continue stirring at high speed for 10 minutes; then , add 0.5 parts of dispersant polyethylene wax, stir at high speed for 10 minutes; finally, add 7.5 parts of linear low density polyethylene with a melting index of 0.1g / 10min, and add 7.5 parts of linear low density polyethylene with a melting index of 1g / 10min. 27.5 parts, 15 parts of linear low-density polyethylene with a melt index of 40 g / 10 min, mixed evenly at a low speed, added to a twin-screw extruder, melted and blended, extruded, and granulated to obtain a polyethylene composition. The polyethylene composition is cast and stretched to obtain a breathable film product. The weight fraction of each component in the polyethylene composition is shown in Table 1, and the performance of the breathable film ...

Embodiment 3

[0034] Add 30 parts of calcium carbonate with a particle size of 1-10 microns and 20 parts of calcium carbonate with a particle size of 0.2-0.5 microns into a high-speed mixer, set the temperature at 110-120°C, stir at high speed for 10 minutes, and then add 0.5 parts of titanate The coupling agent continues to stir at high speed for 10 minutes; then, add 0.5 parts of dispersant polyethylene wax, and stir at high speed for 10 minutes; finally, add 7.5 parts of linear low density polyethylene with a melt index of 0.1g / 10min, and a melt index of 2g / 10min 27.5 parts of linear low density polyethylene, 15 parts of linear low density polyethylene with a melt index of 40g / 10min, mixed evenly at a low speed and then added to a twin-screw extruder, extruded and pelletized after melt blending to obtain poly vinyl composition. The polyethylene composition is cast and stretched to obtain a breathable film product. The weight fraction of each component in the polyethylene composition is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com