Sound-absorbing method and sound-absorbing device for magnetic levitation traffic line

A technology of sound-absorbing device and traffic line, applied in the direction of roads, tracks, buildings, etc., can solve the problems that are rarely involved in research, sound source location, reasonable covering location and area, life span, safety in-depth research, no formation Maglev noise reduction technology and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

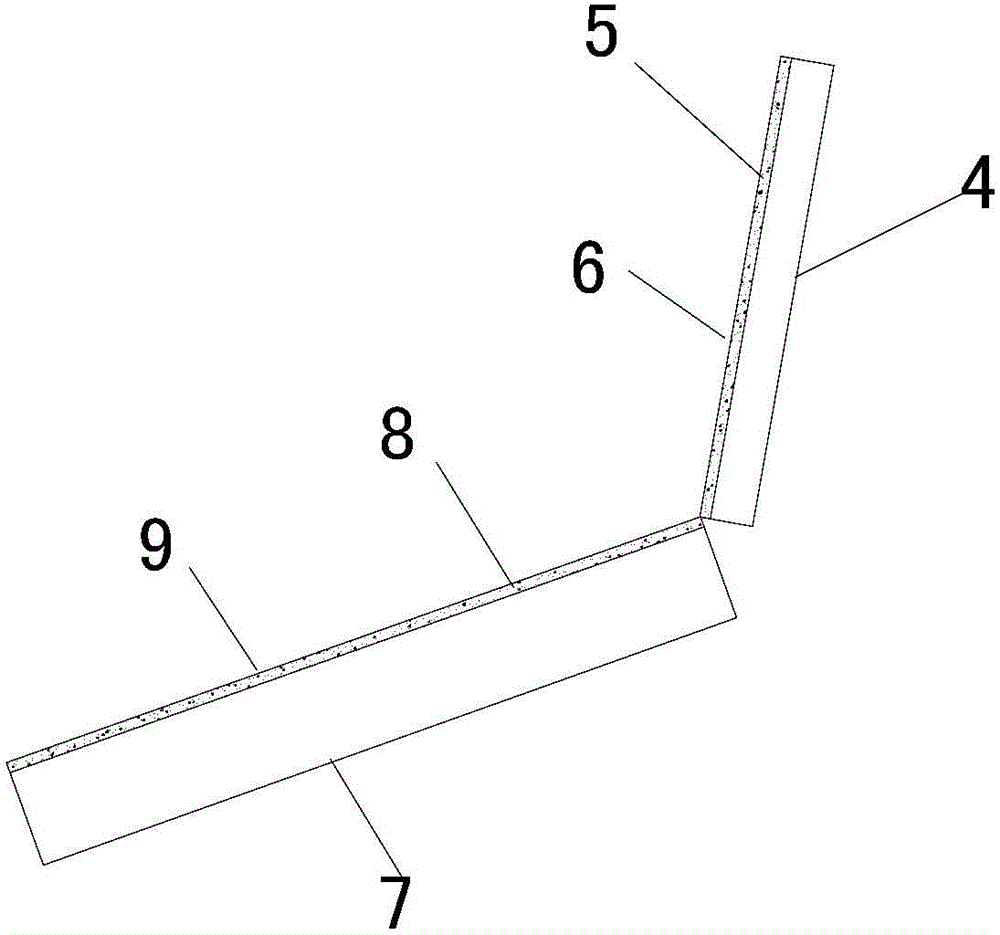

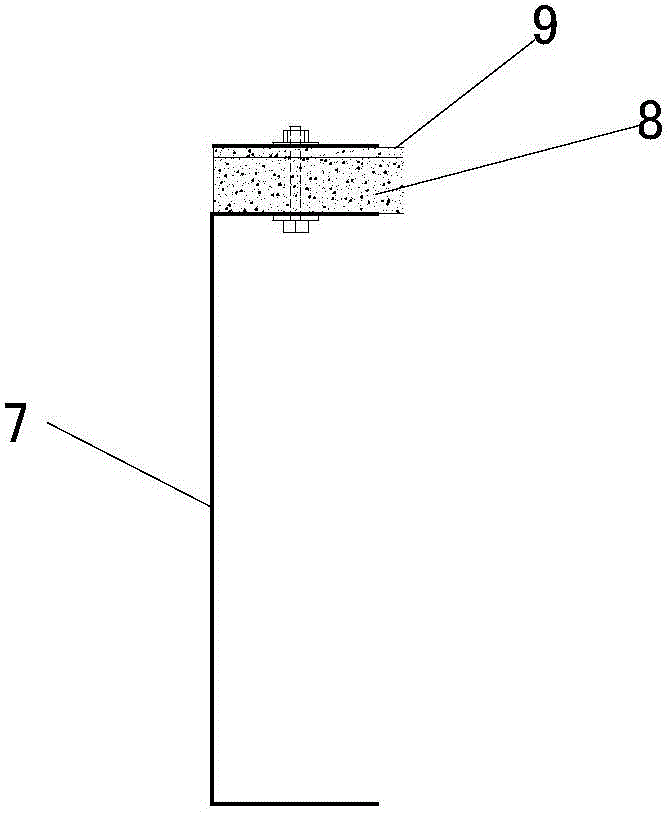

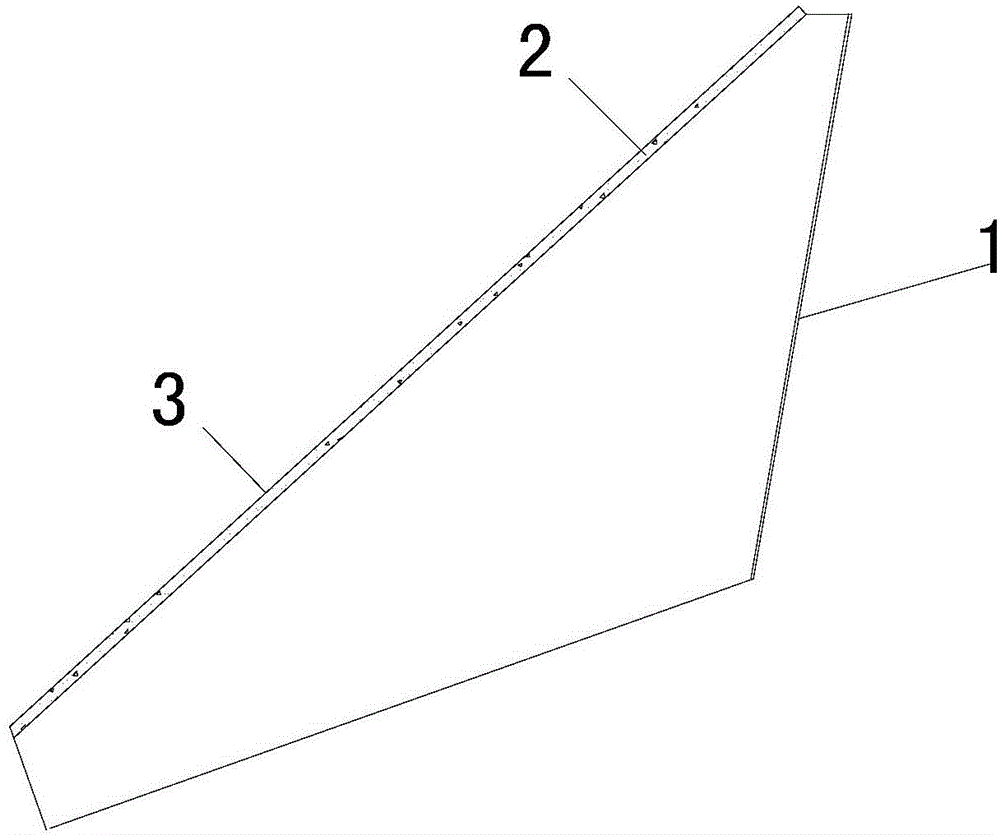

[0026] The sound absorption method of the maglev traffic line of the present invention comprises the following measures:

[0027] a. Install sound-absorbing devices on the track beam at the middle and lower part of the track beam, that is, 100mm below the limit line at the bottom of the train; according to the analysis of the maglev sound source, the directionality of the maglev train passing by is obvious. Combined with the sound absorption theory, The closer the sound-absorbing material is laid to the mirrored sound source on the beam, the better the sound-absorbing effect will be. The invention adopts the geometric sound ray method to determine that the mirrored sound source point on the maglev track beam is outside the limit range of the vehicle, which provides technical support for laying sound-absorbing materials and ensuring driving safety.

[0028] In order to ensure the safety of the location where the sound-absorbing material is laid, while ensuring the sound-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com