Solar photovoltaic roof structure body

A solar photovoltaic and structure technology, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of high-altitude manual operation, low safety factor, low work efficiency, etc., which is a waste of human resources, and improve the operation safety factor. and operation efficiency, avoid roof damage, reduce the effect of dangerous operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

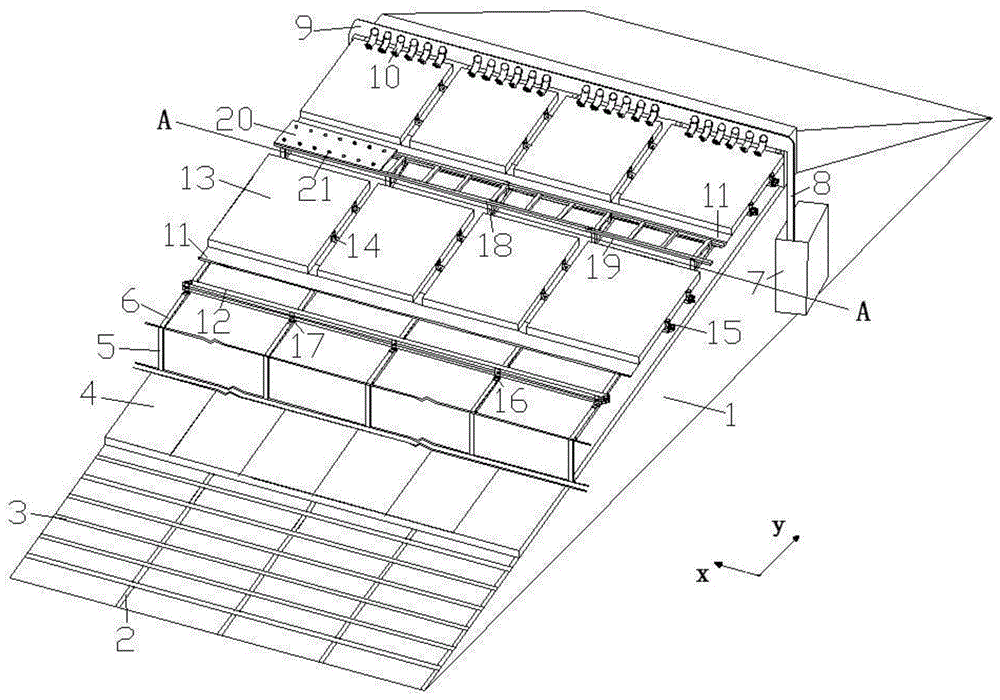

[0034] The solar light roof structure in this embodiment is a solar photovoltaic roof structure applied to industrial plants.

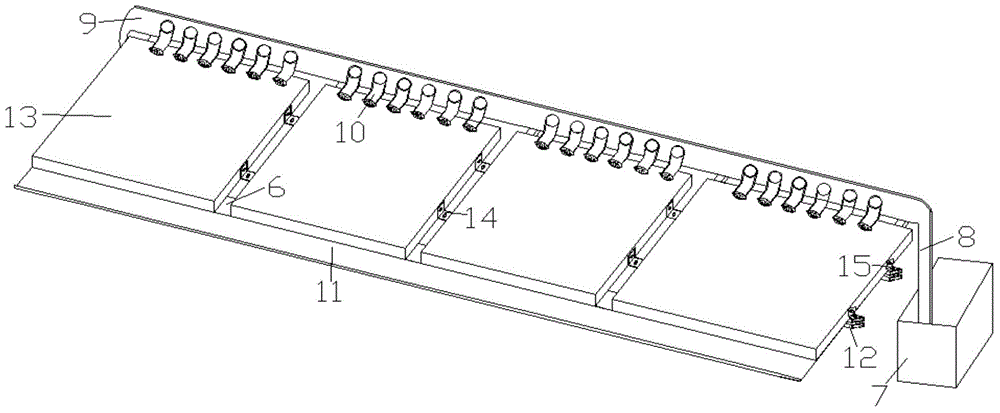

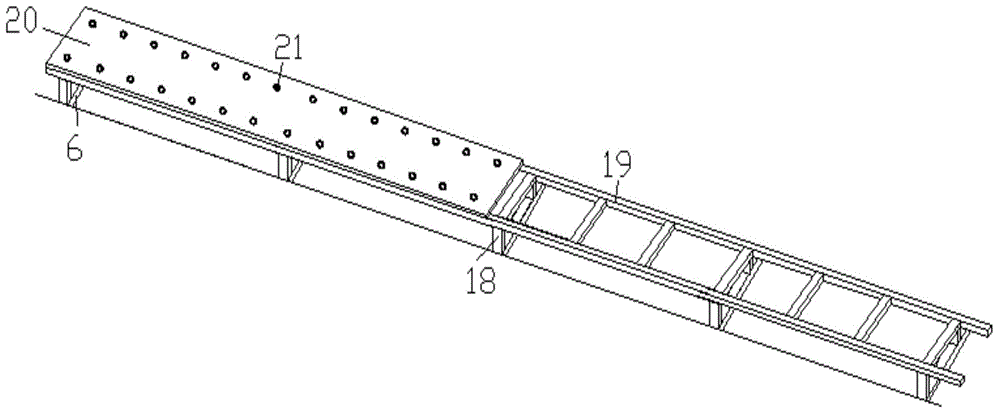

[0035] like figure 1 As shown, the solar photovoltaic roof structure of an industrial plant in this embodiment includes a roof body 1 (including roof truss beams 2, roof purlins 3 and roof color steel plates 4), a support frame fixed on the roof body 1 (including support frame columns 5 and Supporting frame beam 6), photovoltaic modules 13 installed on the supporting frame through guide rails 12, and photovoltaic module cleaning system (including water storage tank 7, water pipeline 8, cleaning pipeline 9, nozzle 10 and cleaning water tank 11) and roof maintenance and Maintenance access (including inspection frame beam 19, inspection frame beam column 18 and pedestrian board 20). figure 1 The part above A-A is a complete system of solar photovoltaic roof structures, and the part below A-A is a solar photovoltaic roof structure that is not drawn in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com