Temperature-controllable diesel generator piston

A diesel generator and piston technology, applied in the direction of pistons, engine components, machines/engines, etc., can solve the problems of poor cooling effect, scrapped piston cylinders, low cooling efficiency, etc., and achieve good cooling effect, long working life, cooling Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

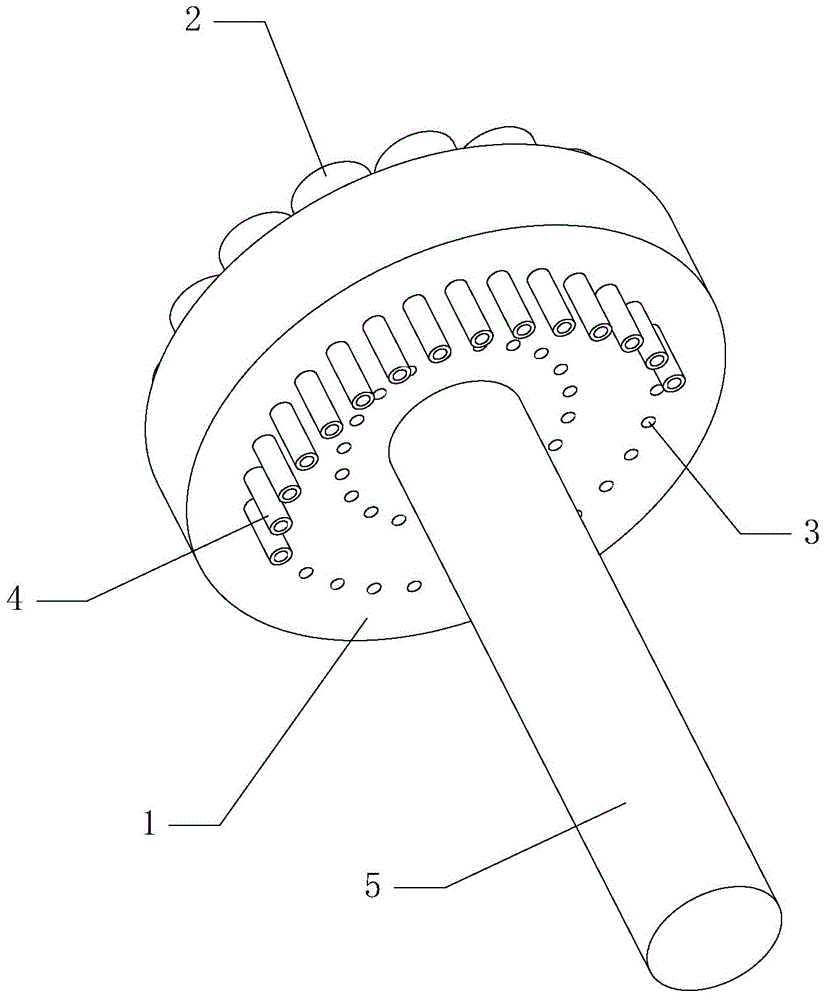

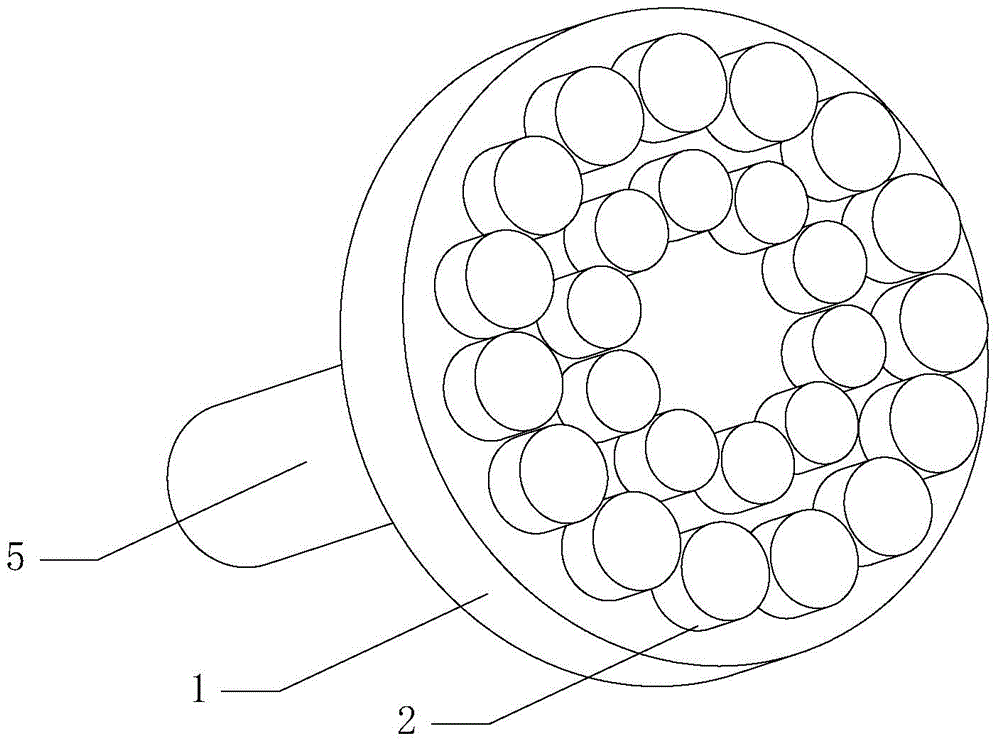

[0027] A temperature-controllable diesel generator piston includes a piston body 1 , a protrusion 2 is provided on the surface of the piston body 1 , and a cooling channel 3 is provided inside the protrusion 2 , and the cooling channel 3 runs through the piston body 1 .

[0028] In this embodiment, the cooling channel 3 includes a cooling medium inflow channel 31 and a cooling medium outflow channel 32 ; the cooling medium inflow channel 31 communicates with the cooling medium outflow channel 32 inside the protrusion 2 .

[0029] It also includes a heat exchange tube 4, the heat exchange tube 4 is divided into a cooling medium inflow tube 41 and a cooling medium outflow tube 42; the cooling medium inflow tube 41 is connected to the cooling medium inflow channel 31;

[0030] Use the heat exchange tube 4 to connect the cooling passage 3 of the piston body 1, and the cooling medium can heat or cool down the piston body 1 through the cooling passage 3; the protrusions 2 are small a...

Embodiment 2

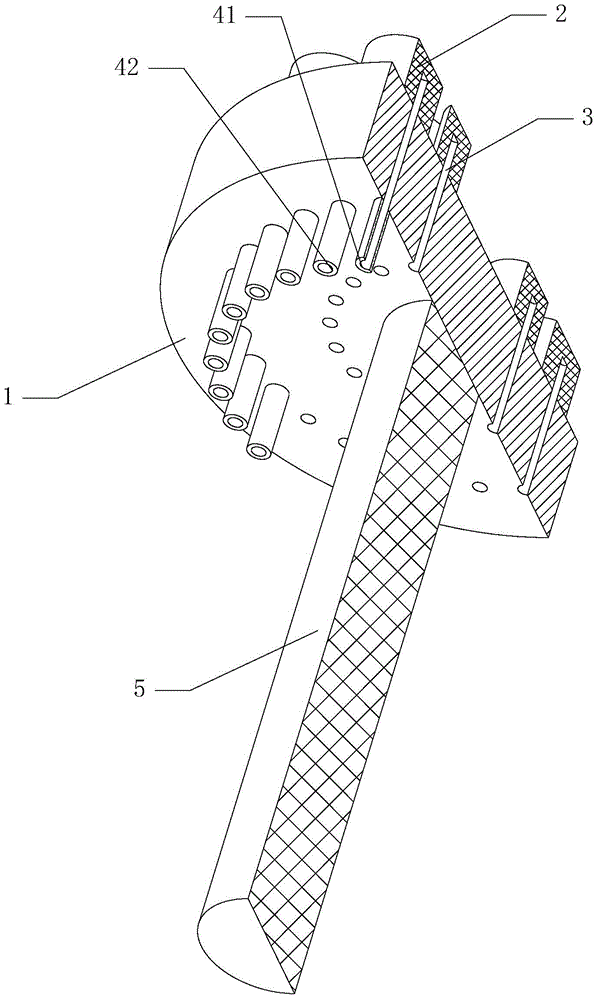

[0037] A temperature-controllable diesel generator piston includes a piston body 1 , a protrusion 2 is provided on the surface of the piston body 1 , and a cooling channel 3 is provided inside the protrusion 2 , and the cooling channel 3 runs through the piston body 1 .

[0038] In this embodiment, the cooling channel 3 includes a cooling medium inflow channel 31 and a cooling medium outflow channel 32 ; the cooling medium inflow channel 31 communicates with the cooling medium outflow channel 32 inside the protrusion 2 .

[0039] It also includes a heat exchange tube 4, the heat exchange tube 4 is divided into a cooling medium inflow tube 41 and a cooling medium outflow tube 42; the cooling medium inflow tube 41 is connected to the cooling medium inflow channel 31;

[0040] Use the heat exchange tube 4 to connect the cooling passage 3 of the piston body 1, and the cooling medium can heat or cool down the piston body 1 through the cooling passage 3; the protrusions 2 are small a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com