Elastic compensation device/group/bracket and absorption tower device

An elastic compensation and device group technology, applied in the direction of spring/shock absorber, shock absorber, gas shock absorber, etc., can solve problems such as inconvenient operation, and achieve a compact structure with convenient maintenance and replacement, compact structure and good shape structure. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

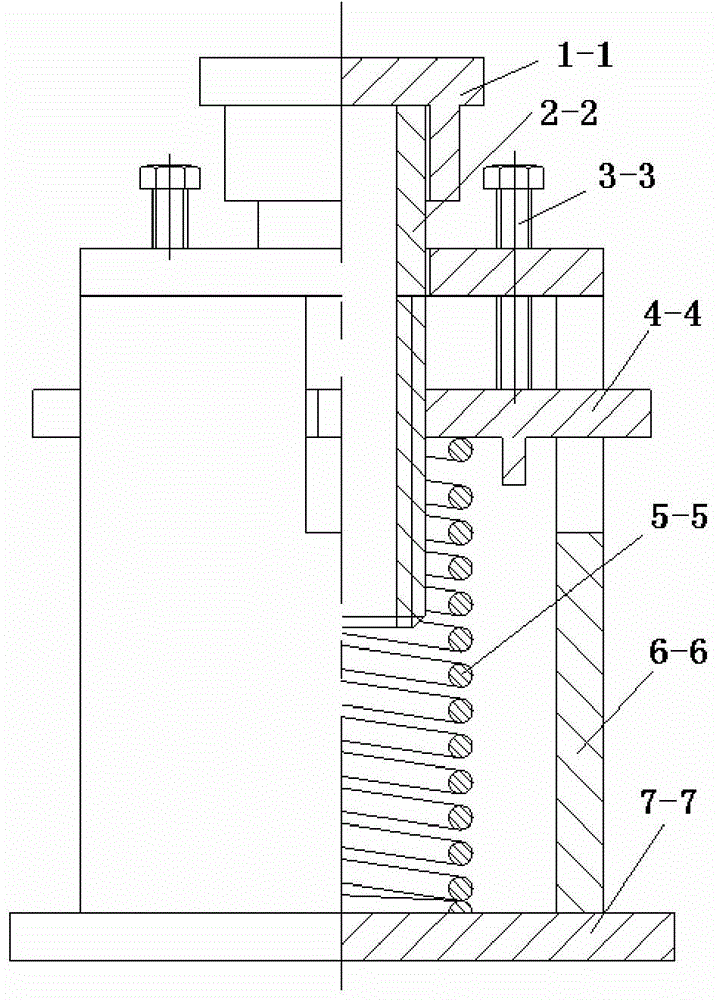

[0046] figure 2 As shown, an elastic compensation device of the present invention has a top plate 1-1, a pressure plate 4-4, an elastic shock absorbing part 5-5, a bottom plate 7-7, a shell 6-6, a load column 2-2 and several setting bolts 3 -3. The load column 2-2, the pressure plate 4-4 and the elastic shock absorbing part 5-5 are arranged in the shell 6-6, and the shell 6-6 is firmly connected with the bottom plate 7-7; the elastic shock absorbing part 5-5 is located on the bottom plate 7- Between the upper end surface of 7 and the lower end surface of the pressure plate 4-4, the elastic action end surface is respectively in contact with the upper end surface of the bottom plate 7-7 and the lower end surface of the pressure plate 4-4; 2-2 is fastened to the pressing plate 4-4; the top plate 1-1 is fastened to the load column 2-2.

Embodiment 2

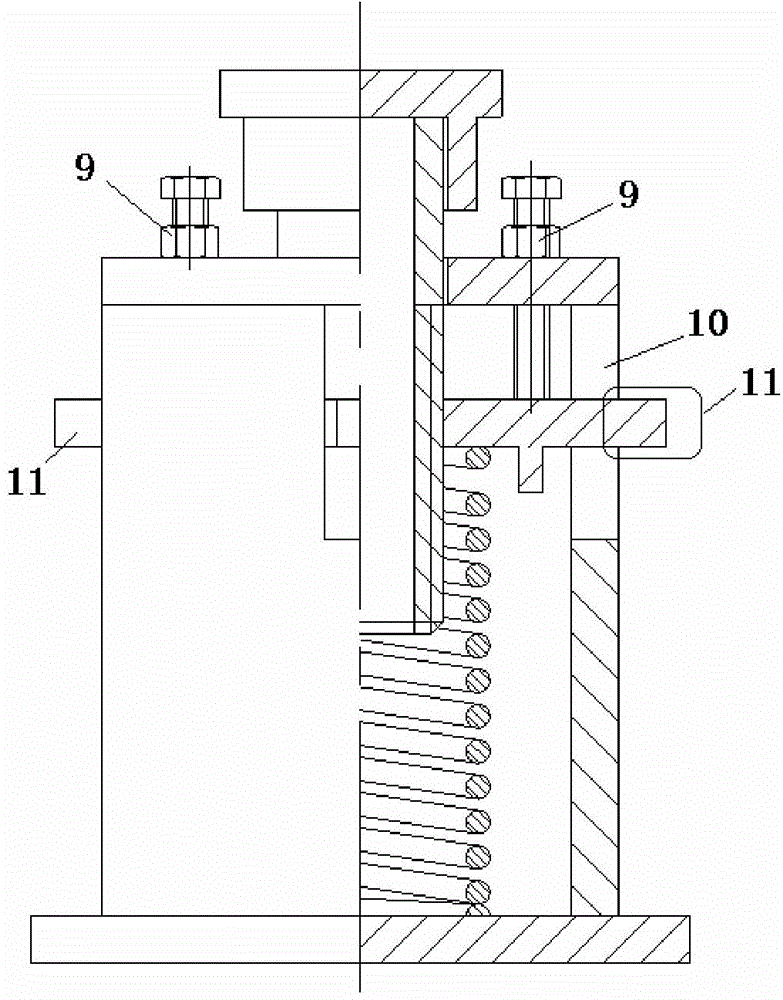

[0048] image 3 shown in figure 2 On the basis of the scheme shown, a lock nut 9 is added to further enhance the locking effect. Among them, the schematic diagram of the fastening connection between the load column 2-2 and the pressure plate 4-4 is as follows Figure 4 As shown, the fastening method selected in the figure is threaded connection. In this embodiment, the middle of the pressing plate 4-4 is provided with a threaded through hole that matches the external thread of the load column 2-2; the edge is provided with a guide and limit protrusion 10 that matches the outer shell 6-6 (the outer shell 6-2). 6 is correspondingly provided with the guide limit chute 11 that is matched with it, the guide limit protrusion 10 and the guide limit chute 11 jointly form the guide limit device that limits the movable space of the pressing plate 4-4), the specific structure is as Figure 5shown.

Embodiment 3

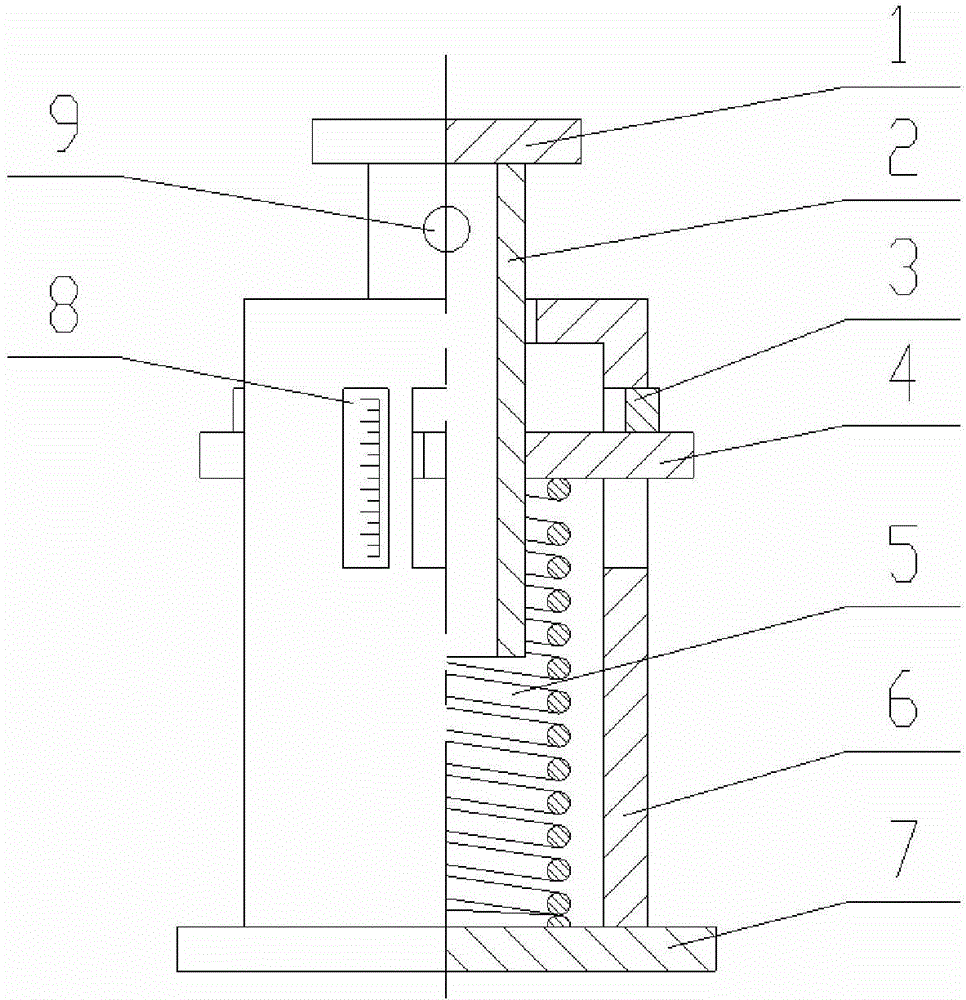

[0050] Figure 6 shown in image 3 On the basis of the scheme shown, a scale indicating part 8-8 is added to provide a numerical indication of the load borne by the top plate, to quantify the predetermined load to the displacement distance of the pressure plate 4-4, and to accurately control the elastic deformation error after precompression Within the allowable error range of the predetermined load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com