Harmonic reducer and machining process thereof

A harmonic reducer and processing technology, which is applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problem that the concentricity and position of the output shaft cannot be guaranteed, reduce the service life of the reducer, and reduce the product Accuracy and other issues, to achieve the effect of simple structure, reduce assembly error, and improve product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

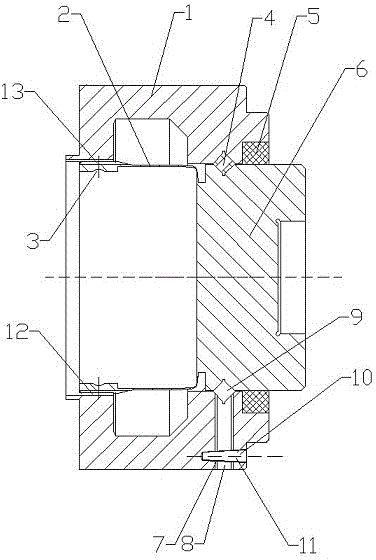

[0036] Examples such as figure 1 As shown, a harmonic reducer includes a rigid wheel 1, and a flexible output device is connected to the rigid wheel 1. The flexible output device includes a flexible wheel 2 and an output shaft 6, and the flexible wheel 2 and the output shaft 6 are integrally formed. .

[0037] The output shaft 6 and the rigid wheel 1 are rotationally connected by a cross roller bearing, the cross roller bearing is composed of a needle groove 9 and a cross needle roller 4, and the needle groove 9 is formed integrally with the rigid wheel 1 The outer needle groove and the inner needle groove integrally processed with the output shaft 6.

[0038] The end of the output shaft 6 is sealed and connected with the rigid wheel 1 through the sealing ring 5 .

[0039] The flexible spline 2 and the rigid spline 1 are driven through the meshing transmission of the internal teeth 12 and the external teeth 13;

[0040] The flexspline 2 is provided with a bearing raceway 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com