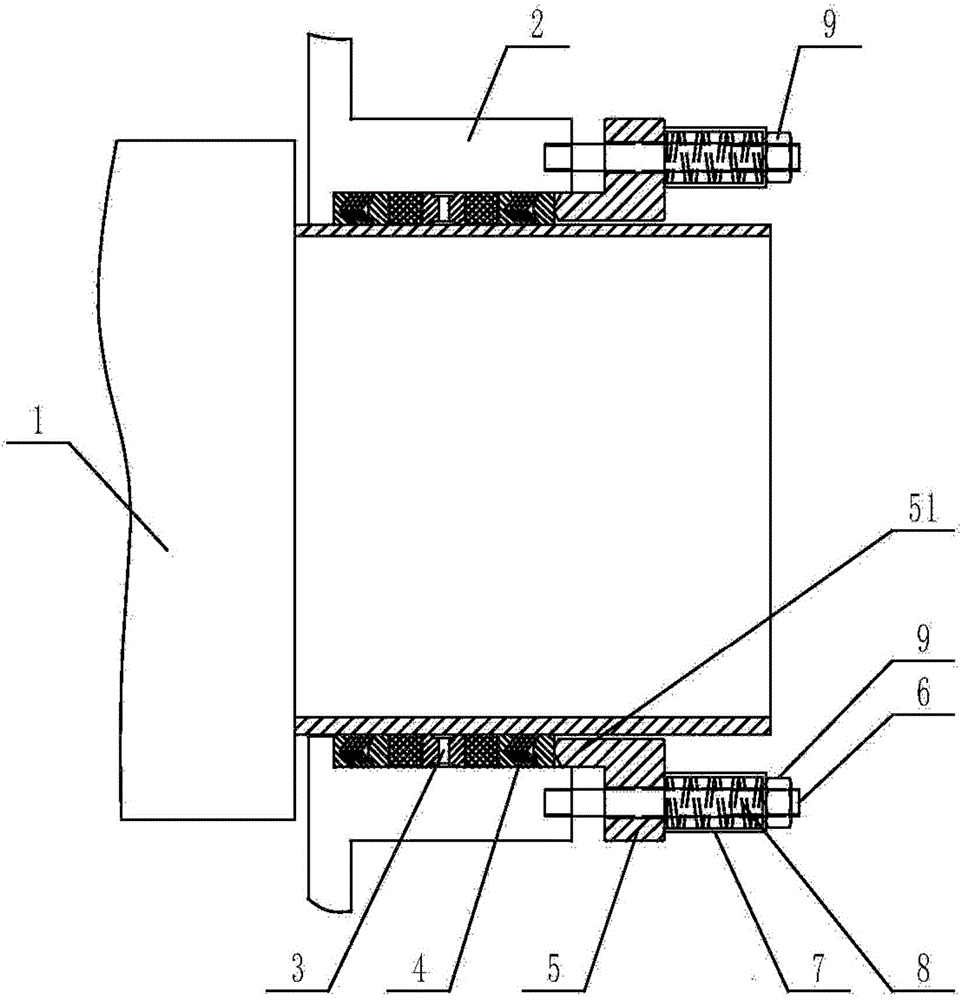

Shaft sealing device

A shaft seal and hard seal technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of easy wear and seal failure of the seal ring 4, so as to avoid wear and aging, improve the sealing effect, and slow down aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

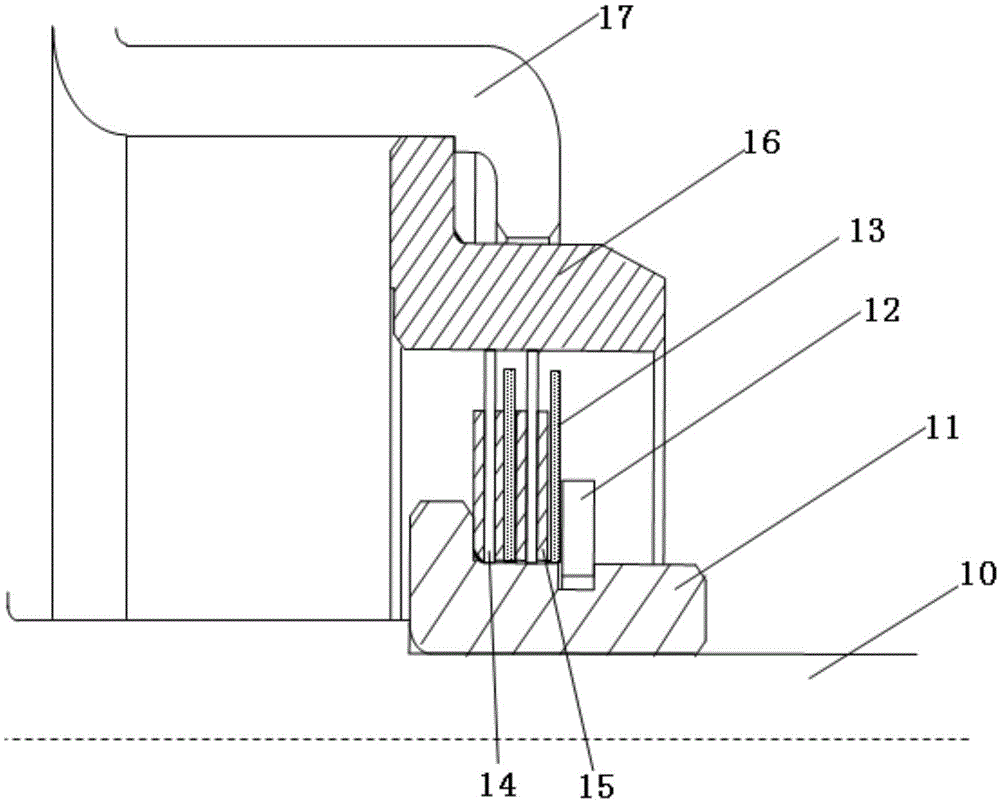

Embodiment 1

[0036] Embodiment 1, the shaft sealing device such as figure 2 As shown, it includes a rotating shaft 10, a labyrinth inner sleeve 11, a snap ring 12, a hard seal ring 13, a spacer ring 15, a soft seal ring 14, a labyrinth outer sleeve 16, and a seal ring seat 17;

[0037] The sealing ring seat 17 is pivotably sleeved on the rotating shaft 10;

[0038] The labyrinth jacket 16 is fixed on the sealing ring seat 17;

[0039] The labyrinth inner sleeve 11 is fixedly sleeved on the rotating shaft 10;

[0040] The labyrinth outer cover 16, the labyrinth inner cover 11, and the rotating shaft 10 are coaxial, and the labyrinth outer cover 16 is set outside the labyrinth inner cover 11;

[0041] The labyrinth inner sleeve 11 is provided with an annular groove in the middle;

[0042] The inner edge of the clasp 12 is embedded in the annular groove, and fixed on the outer edge of the middle part of the labyrinth inner sleeve 11;

[0043] The labyrinth inner sleeve 11 has a boss on t...

Embodiment 2

[0055] Based on the first embodiment, there may be one or more sets of hard sealing rings 13 , spacer rings 15 , soft sealing rings 14 and spacer rings 15 .

[0056] The more groups of hard seal ring 13, spacer ring 15, soft seal ring 14 and spacer ring 15, the better the sealing effect.

[0057] Preferably, there are two groups of hard seal rings 13, spacer rings 15, soft seal rings 14, and spacer rings 15. The ring, the soft sealing ring, and the spacer ring are sequentially sleeved and fixed on the outer edge of the labyrinth inner sleeve 11 between the snap ring 12 and the boss at the bottom outer edge of the labyrinth inner sleeve 11 . Two sets of hard sealing rings 13, spacer rings 15, soft sealing rings 14, and spacer rings 15 can not only achieve ideal sealing effects, but also effectively control costs.

Embodiment 3

[0059] Based on the first embodiment, the hard sealing ring 13 can be made of steel or other hard non-metallic materials;

[0060] The soft sealing ring 14 can be made of polytetrafluoroethylene, rubber or polycarbonate;

[0061] The spacer ring 15 can be made of steel or epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com