Trans-critical cycle double-stage heat absorption providing composite refrigeration system

An absorption cycle, composite refrigeration technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of inability to provide a large amount of waste heat, a large amount of external energy input, insufficient waste heat utilization, etc., to achieve good independence and Scope of application, good economy, the effect of improving the available waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

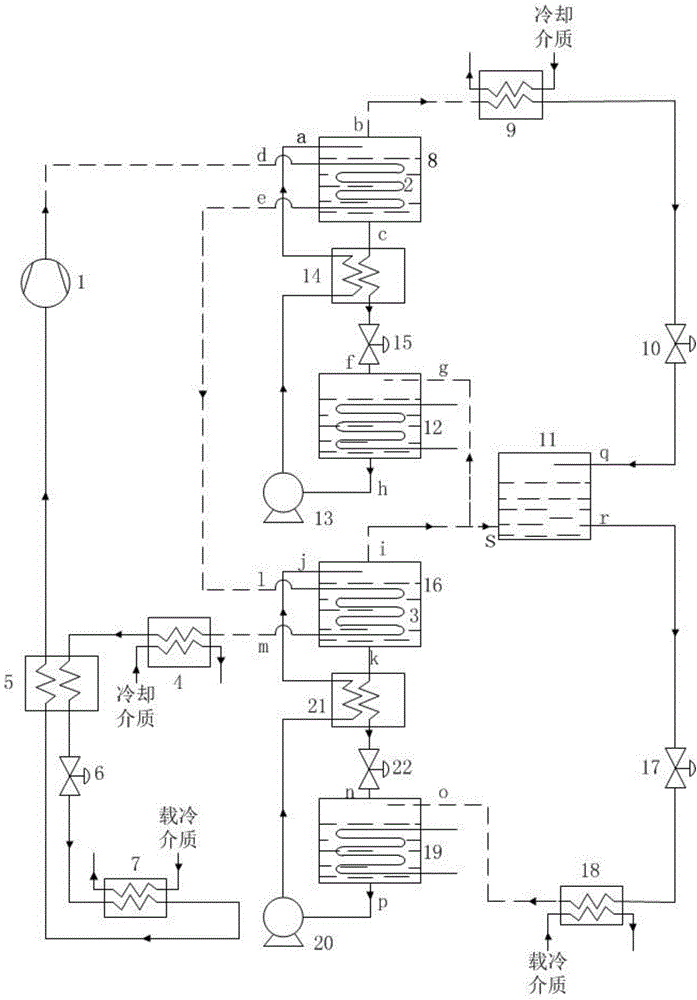

[0040] Such as figure 1 As shown, a transcritical cycle provides a composite refrigeration system with two-stage absorption heat, which consists of a transcritical compression subsystem, a high-pressure absorption subsystem, and a low-pressure absorption subsystem;

[0041] The steam outlet b of the high-pressure generator 8 of the high-pressure absorption subsystem is connected to the inlet of the condenser 9, the outlet of the condenser 9 is connected to the inlet of the first throttling device 10, and the outlet of the first throttling device 10 is connected to the condenser evaporator The liquid inlet q of 11 is connected, the liquid outlet h of the high-pressure absorber 12 is connected with the inlet of the first circulation pump 13, and the outlet of the first circulation pump 13 is connected with the first channel inlet of the first solution heat exchanger 14, and the first solution The first channel outlet of the heat exchanger 14 is connected with the liquid inlet a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com