Sensor fault detection device

A technology of sensor failure and detection device, applied in the direction of instruments, etc., can solve the problems of increasing the workload of maintenance personnel, wasting time, occupying space, etc., and achieving the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

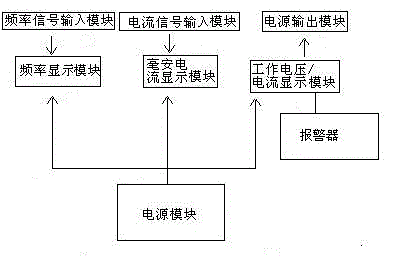

[0008] Such as figure 1 As shown, the sensor fault detection device has a power module, and the alternating current is converted into direct current through the power module to supply power for each part of the whole device. The frequency display module detects and displays the analog signal output function of the mine sensor. The function of the mA current display module is to detect and display the output function of the mA current signal of the mine transmission switch sensor. The frequency signal input module and the current signal input module can judge whether the signal output interface of the mine sensor is normal. The power output module supplies power to the mine sensor to be detected, and at the same time displays the current working parameters of the mine sensor through the working voltage / working current display module. The working voltage / working current display module is connected with an alarm.

[0009] Wherein, the frequency signal input module adopts a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com