Structure for testing residual stress on thick film silicon material on insulating substrate

A technology for testing structures on an insulating substrate, applied in the direction of applying stable tension/pressure to test material strength, force/torque/power measuring instruments, measuring devices, etc., can solve problems such as unstable measurement data accuracy, and achieve The test process and test parameter values are stable, the test method is simple, and the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

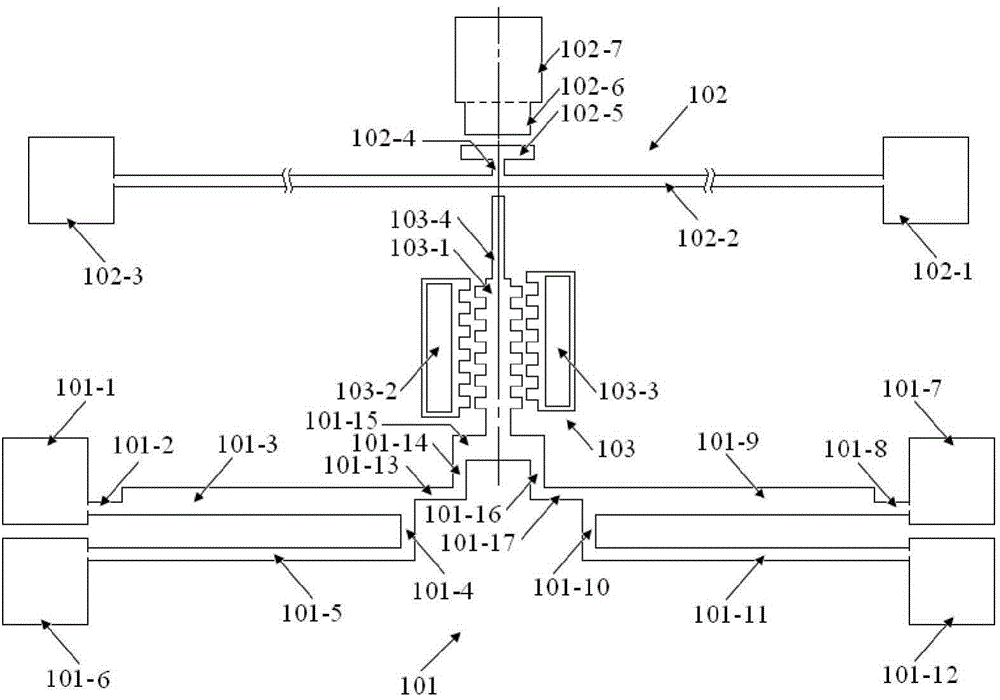

[0020] Attached below figure 1 The present invention will be further described.

[0021] The test structure consists of three parts: a relative electrothermal drive unit 101 ; a deflection measurement unit 103 with a micrometer vernier; and an electrostatically driven fixed beam unit 102 .

[0022] The relative electrothermal driving unit 101 is composed of two identical left and right MEMS conventional electrothermal actuators connected in the first part and the second part. The first MEMS electrothermal actuator on the left is composed of the first anchor area 101-1, the first thin beam 101-2, the first wide beam 101-3, the first connecting beam 101-4, the first thermal expansion thin beam 101-5, The second anchor region 101-6 is connected clockwise. The second part of the MEMS electrothermal actuator on the right consists of a third anchor area 101-7, a second thin beam 101-8, a second wide beam 101-9, a second connecting beam 101-10, and a second thermal expansion thin b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com