Damping-structure-optimized blade testing experiment table and experimental method thereof

A technology of damping structure and testing experiment, which is applied in the field of experimental devices, can solve problems such as huge centrifugal force, and achieve the effect of ensuring the optimization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

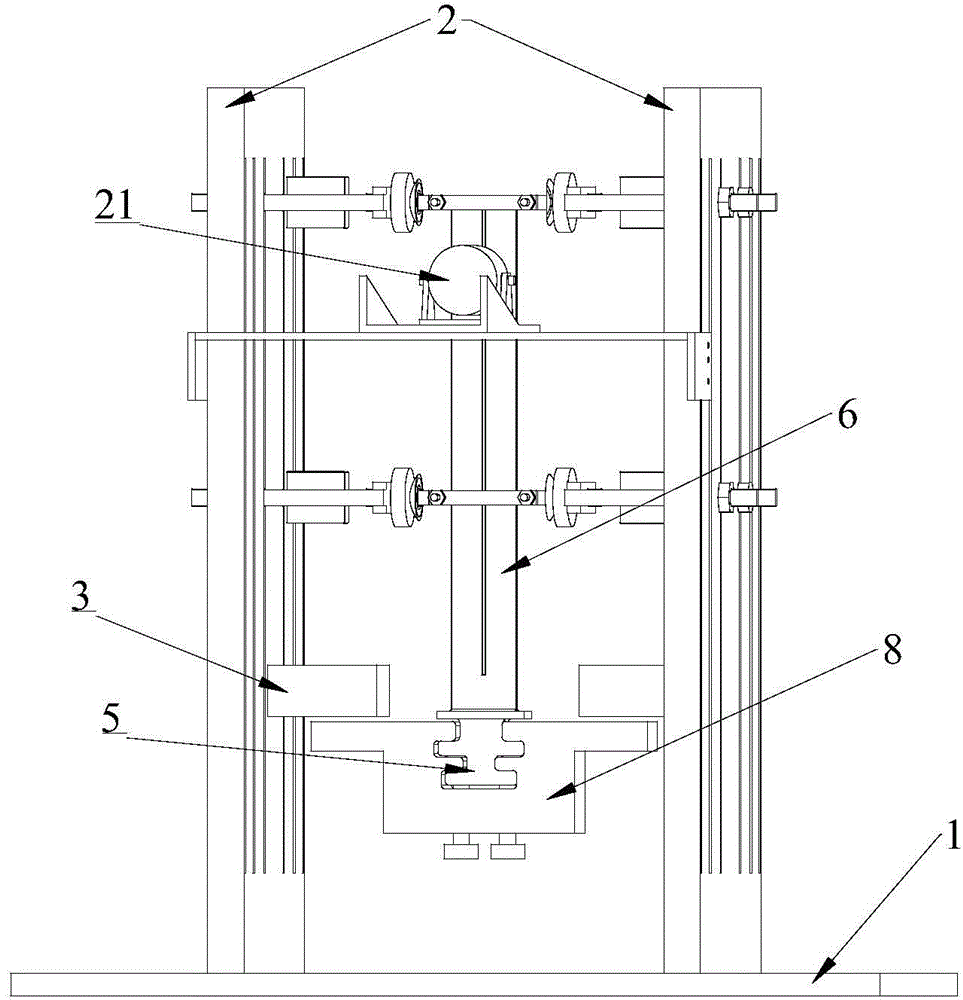

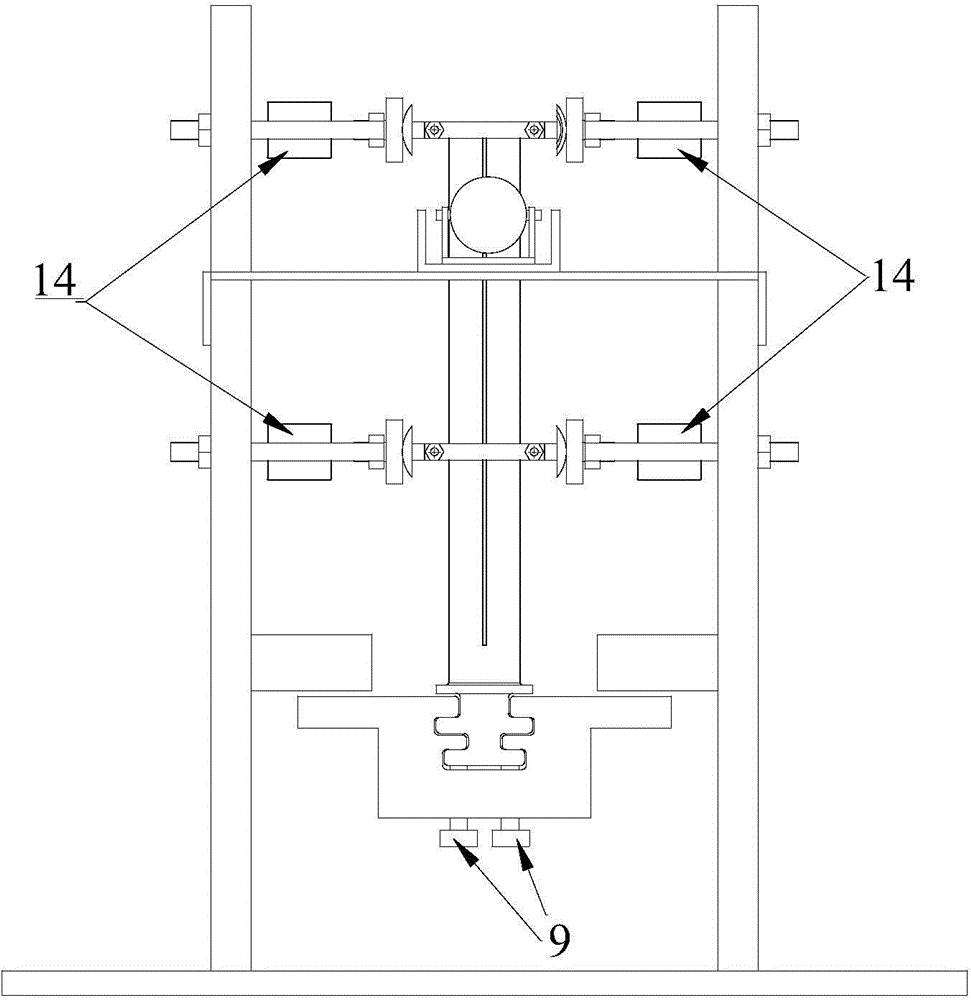

[0040] see figure 1 and figure 2 , the present invention aims to test the damping structure optimization performance of steam turbine damping blades. Based on this purpose, a set of damping structure optimization consisting of a base platform, a blade root fixing device, a damping structure device, an excitation loading device and a measuring device is designed. Blade test bench.

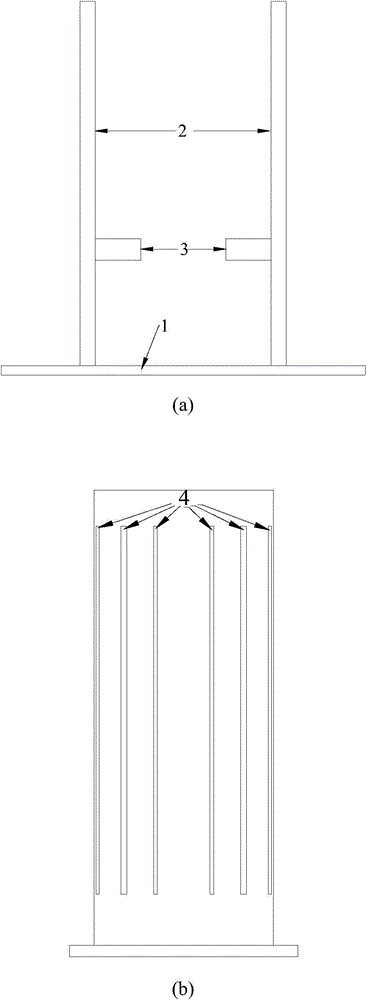

[0041] see image 3 , firstly, the basic bench for the test is introduced. The test bench is composed of a bottom plate 1 and two side plates 2 welded thereon, and two pads 3 are welded on the side plates for fastening the blade root fixing device. The bottom plate 1 is placed on the foundation platform, the upper surface of the blade root groove 8 is closely attached to the lower surface of the pad 3, and the three-dimensional laser vibrometer bracket is fixed on the bottom plate 1 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com