A Prediction Method of Durable and Instantaneous Limit Mechanical Properties of Polymers

A polymer and mechanical technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of large workload, small predicted time scale, and unsatisfactory time-temperature equivalent performance, achieving wide time scale, Simplify the test process and predict the effect of the method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

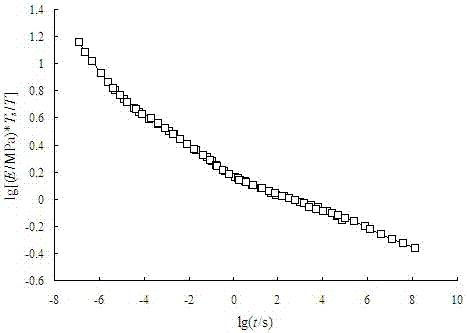

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described.

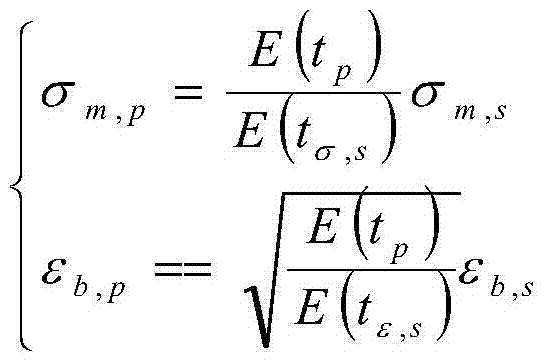

[0012] Predict the tensile strength and breaking strain of nitrate plasticized polyether (NEPE) propellant in the ignition state at -20℃, and predict whether permanent damage will occur after storage for 5 years. It is known that the glass transition temperature of the propellant is -47.8°C, and the tensile strength at room temperature σ m =0.75MPa, fracture strain ε b =1.13 (test conditions: 25°C, 100mm / min). The ignition peak time of the propellant-charged engine is t f =25ms, the stress at the most dangerous part of the grain column during storage is not greater than 0.20MPa, the strain is not greater than 0.15, and the upper limit of the storage temperature is 25°C.

[0013] Step 1, condition selection and sample preparation.

[0014] In the stage of condition selection and sample preparation, the predicted objects are all viscoelastic materials.

[0015] The materials that need ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com